Gihan Hewage, Research Associate, Lux Research 12.06.16

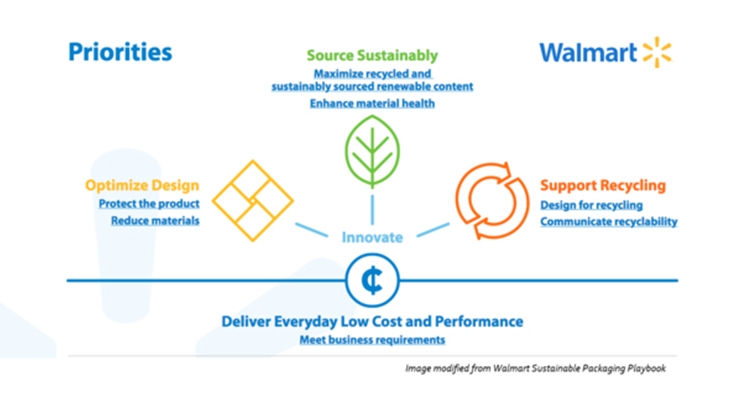

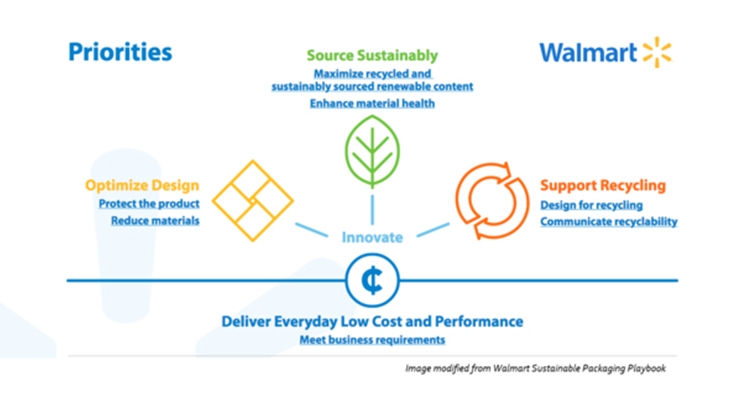

Walmart recently released its “Sustainable Packaging Playbook,” where it provides best practices for suppliers looking to improve and innovate sustainable packaging. It emphasizes that these sustainable packaging best practices are meant to compliment business needs, which is to say going “green” does not mean sacrificing performance. Walmart highlighted three innovation pillars in its playbook:

• Optimize design: Protect the product while limiting material used

• Source sustainably: Maximize the amount of recycled and sustainably sourced renewable content while minimizing materials that are harmful to human health and the environment

• Support recycling: Use materials in forms that can be recycled while communicating how consumers should recycle the packaging

In light of this playbook, we have identified three innovative technologies in the packaging space that promote sustainability while complimenting business needs:

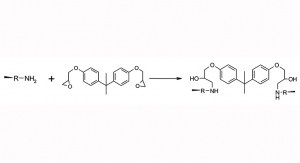

• Polyethylene furanoate (PEF): Compared to polyethylene terephthalate (PET), PEF has improved barriers to O2, CO2, and water, which could potentially allow for reduced material. Companies, such as Avantium, are developing PEF using bio-based feedstocks, such as cellulosic sugars, instead of the fossil-based sources traditionally used for PET.

However, while a recycling stream dedicated to PEF has not yet been developed, PEF can be introduced into the PET recycling stream to a small extent. It is thereby reasonable to envision a straightforward development of a PEF-only recycling stream.

• Pulp-based packaging: While use of pulp-based packaging for applications like egg cartons has been prevalent for decades, a few companies have recently modernized this technology. PulpWorks, for example, has developed an environmentally- and consumer-friendly pulp-based alternative to PVC and PET blister packs. Likewise, ecoXpac is developing a fiber-based replacement for glass beer bottles – not only would this bottle come from more sustainable sources, but its lighter weight compared to glass bottles should help decrease shipping costs. Because these materials are cellulosic in nature, their incorporation into paper recycling streams is straightforward.

• Improved coatings: Given difficulties with recycling polyethylene (PE) and wax-coated paper, a handful of companies are working to develop more sustainable coatings. TopChim, for example, develops vegetable-oil-loaded nanoparticle coatings with tunable hydrophobicity, grease resistance, water vapor transmission rate, and flame retardancy. Its materials also improve the recyclability of coated paper over traditional PE and wax coatings. Similarly, Smart Planet Technologies develops petroleum-based coatings with increased water and oil barriers, enabling thinner and cheaper coatings. Additionally, its mixed-material folding cartons have been certified as “Widely Recycled” by How2Recycle.

Multinationals like Walmart and IKEA drive growth in the bio-based materials and chemicals (BBMC) space with sustainability initiatives like this playbook. However, it should be noted that this playbook does not simply call out for products that are “greener.” In fact, it calls for sustainable materials that can better protect products with reduced material following a recent trend in the BBMC space for high-performing bio-based materials. Those looking to improve sustainability should follow in Walmart’s lead by looking for measures that are not just green, but also support business needs.

Gihan Hewage is a Research Associate on the Bio-based Materials and Chemicals Intelligence team at Lux Research, which provides strategic advice and on-going intelligence for emerging technologies. For more information, visit Lux Research.

• Optimize design: Protect the product while limiting material used

• Source sustainably: Maximize the amount of recycled and sustainably sourced renewable content while minimizing materials that are harmful to human health and the environment

• Support recycling: Use materials in forms that can be recycled while communicating how consumers should recycle the packaging

In light of this playbook, we have identified three innovative technologies in the packaging space that promote sustainability while complimenting business needs:

• Polyethylene furanoate (PEF): Compared to polyethylene terephthalate (PET), PEF has improved barriers to O2, CO2, and water, which could potentially allow for reduced material. Companies, such as Avantium, are developing PEF using bio-based feedstocks, such as cellulosic sugars, instead of the fossil-based sources traditionally used for PET.

However, while a recycling stream dedicated to PEF has not yet been developed, PEF can be introduced into the PET recycling stream to a small extent. It is thereby reasonable to envision a straightforward development of a PEF-only recycling stream.

• Pulp-based packaging: While use of pulp-based packaging for applications like egg cartons has been prevalent for decades, a few companies have recently modernized this technology. PulpWorks, for example, has developed an environmentally- and consumer-friendly pulp-based alternative to PVC and PET blister packs. Likewise, ecoXpac is developing a fiber-based replacement for glass beer bottles – not only would this bottle come from more sustainable sources, but its lighter weight compared to glass bottles should help decrease shipping costs. Because these materials are cellulosic in nature, their incorporation into paper recycling streams is straightforward.

• Improved coatings: Given difficulties with recycling polyethylene (PE) and wax-coated paper, a handful of companies are working to develop more sustainable coatings. TopChim, for example, develops vegetable-oil-loaded nanoparticle coatings with tunable hydrophobicity, grease resistance, water vapor transmission rate, and flame retardancy. Its materials also improve the recyclability of coated paper over traditional PE and wax coatings. Similarly, Smart Planet Technologies develops petroleum-based coatings with increased water and oil barriers, enabling thinner and cheaper coatings. Additionally, its mixed-material folding cartons have been certified as “Widely Recycled” by How2Recycle.

Multinationals like Walmart and IKEA drive growth in the bio-based materials and chemicals (BBMC) space with sustainability initiatives like this playbook. However, it should be noted that this playbook does not simply call out for products that are “greener.” In fact, it calls for sustainable materials that can better protect products with reduced material following a recent trend in the BBMC space for high-performing bio-based materials. Those looking to improve sustainability should follow in Walmart’s lead by looking for measures that are not just green, but also support business needs.

Gihan Hewage is a Research Associate on the Bio-based Materials and Chemicals Intelligence team at Lux Research, which provides strategic advice and on-going intelligence for emerging technologies. For more information, visit Lux Research.