10.17.18

Evonik Corporation released the results of its first U.S. landfill biogas upgrading installation at Enerdyne’s large-scale biomethane production facility at Lawrence, Kansas.

Since May, the plant has been running a membrane system to remove carbon dioxide at 1,600 standard cubic feet per meter feed flow with two percent methane slip. Besides desulfurization and water removal, the facility operates with a proprietary system to remove VOC’s, siloxanes, oxygen, and moisture which was designed and fabricated by Advanced Biogas Systems, an affiliate of Enerdyne.

“The Evonik membranes have outperformed the older PSA technology originally installed at the site,” said Steve Allman, technical director at Enerdyne.

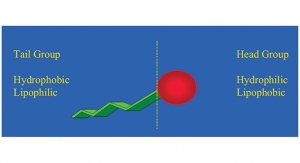

Evonik’s SEPURAN hollow-fiber membranes have the highest CO2/CH4 selectivity. This exceptional selectivity enables high purity RNG with superior methane efficiency and low methane slip.

“The SEPURAN Green membranes have proven their performance in North America landfill gas operations, adding to the more than 150 biogas upgrading installations operating worldwide,” said Mimi Schaefer, group manager, membranes, Americas at Evonik.

The SEPURAN product family includes membranes for upgrading biogas, nitrogen generation, helium and hydrogen recovery, and natural gas sweetening. These are produced at Evonik’s site in Schörfling, Austria. The neighboring Evonik site in Lenzing produces the high-performance polymer raw material.

Photo courtesy Evonik

Since May, the plant has been running a membrane system to remove carbon dioxide at 1,600 standard cubic feet per meter feed flow with two percent methane slip. Besides desulfurization and water removal, the facility operates with a proprietary system to remove VOC’s, siloxanes, oxygen, and moisture which was designed and fabricated by Advanced Biogas Systems, an affiliate of Enerdyne.

“The Evonik membranes have outperformed the older PSA technology originally installed at the site,” said Steve Allman, technical director at Enerdyne.

Evonik’s SEPURAN hollow-fiber membranes have the highest CO2/CH4 selectivity. This exceptional selectivity enables high purity RNG with superior methane efficiency and low methane slip.

“The SEPURAN Green membranes have proven their performance in North America landfill gas operations, adding to the more than 150 biogas upgrading installations operating worldwide,” said Mimi Schaefer, group manager, membranes, Americas at Evonik.

The SEPURAN product family includes membranes for upgrading biogas, nitrogen generation, helium and hydrogen recovery, and natural gas sweetening. These are produced at Evonik’s site in Schörfling, Austria. The neighboring Evonik site in Lenzing produces the high-performance polymer raw material.

Photo courtesy Evonik