Kerry Pianoforte, Editor12.04.17

Powder coatings unlike some traditional liquid coatings, do not require solvents in their formulation and are considered to be 100 percent solids. Powder coatings are typically applied electrostatically and then oven-cured. The end result is a hard finish that is often tougher than most conventional liquid coatings. Powder coatings can be used for a wide variety of applications and end-use markets such as automotive parts, outdoor furniture, home appliances and metal furniture and architectural metal.

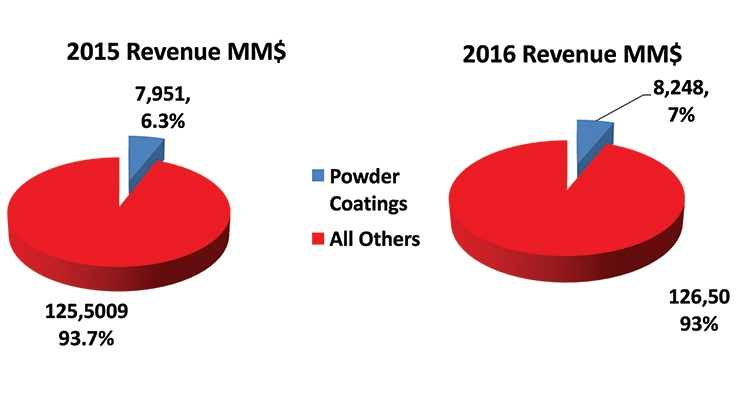

According to Chemark Consulting Group, powder coatings continue to take small meaningful SOM (share-of-the-market) chunks of the global coatings market segment real-estate. While aggregating all types of global coatings together, it grew from $125.5 million in sales revenue in 2015 to $126.5 million in 2016, only a 1.1 percent AGR. Conversely, powder coatings increased its SOM by 1 percent (from 6 percent in 2015 to 7 percent in 2016) and grew at 3.7 times the remainder of the coatings industry rates, at 3.9 percent.

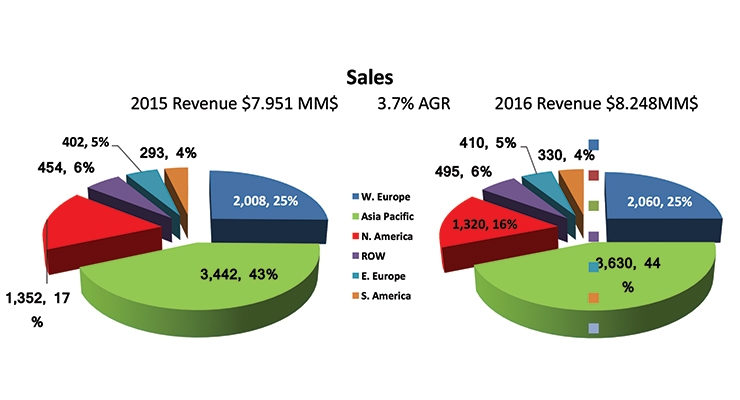

According to Chemark analysts, powder coatings 2015 revenue at $7,951MM in 2015 grew at 3.7 percent to $8,248MM in 2016.

Powder coatings manufacturers Coatings World spoke with reported growth for 2017.

“The powder coatings market has continued to see substantial growth in 2017,” said Michael Cash, president, Industrial Coatings, Axalta Coating Systems. “We attribute this to a strong global economy and the ongoing desire to use the most sustainable and environmentally safe coating solutions. Continued advancements in technology have increased customer confidence in powder coatings, as they prove competitive to liquid solutions in color, design and durability, as well cost of application.”

“Powder coatings comprises a meaningful part of Axalta’s overall business and has proven to be one of our fastest growing segments,” Cash added. “Our sales growth in powder has remained at around twice the market rate consistently over the past four years. This year we’ve had the privilege of supplying powder coatings for monumental, global projects such as the 2016 Rio Olympic and Paralympic torches and the sound barriers installed on Shanghai’s new Metro Line 17.”

Sherwin-Williams saw continued demand for powder coatings globally in 2017 with growth levels above GDP, and expect that this trend will continue throughout 2018. “This demand is in part driven by all the advantages that powder coatings can offer to the finishing marketplace,” said Tabitha McLeish, global marketing director-Powder, General Industrial Coatings, The Sherwin-Williams Company. “As customers continue to push the capability envelope on improved appearance of finishes; the ability to cure at lower temperatures or at much faster cure rates; extended durability for color, gloss and corrosion; thinner films; and greater metallic color space, powder coatings continue to step up to meet the challenge.”

Powder Vs. Liquid

Powder coatings often have an advantage over liquid for a number of reasons.

“In suitable applications, powders provide excellent coverage, especially on corrosion-vulnerable edges,” said McLeish. “They also can deliver higher film thicknesses, up to 99 percent of powders can be recycled or reclaimed and the ability to oven cure induces the chemical reaction that provides a smooth finish.”

“Powder coatings are traditionally applied at a lower cost and are better for the environment, emitting zero or nearly zero volatile organic compounds (VOC),” said Cash. “Overspray can be recycled, eliminating product waste in contrast to liquid waste which can be more energy intensive to recycle and/or dispose of. Powder also has some aesthetic advantages, such as specialty effects like textures, veins and hammertones being easier to achieve than with other coating processes.”

Chemark reports that Asia-Pacific region continues to dominate in size at 43 percent SOM in 2015 and moved up a point to 44 percent SOM a year later in 2016. Western Europe follows at 25 percent for both years, with North America third but losing a SOM point at 16 percent in 2016, down from 17 percent in 2015. The remaining regions combine for a total of 14 percent in 2015 and remaining at 14 percent in 2016.

According to McLeish the heavy equipment market has been strong in both Asia and South America due to the comeback of the construction market in Asia and a stronger agricultural equipment market in South America. “Growth in these regions is expected to continue,” she continued. “Although the military market had been experiencing flat growth, that market is beginning to rebound and some nice growth is anticipated. The U.S. Department of Defense budget increases under the new administration are resulting in contract awards specific to asset protection programs requiring paint for durability and corrosion resistance. Environmental compliance will drive continued powder growth.”

Cash noted that he sees North America following the trend in Europe and China of using more powder coatings in the architectural extrusion market. “For example, in Philadelphia we’ve been constructing our Global Innovation Center using Axalta products throughout and have found, whether it be in extrusions for the building, windows and doors, or lab furniture, that it’s logistically and economically beneficial to coat most of the building components with our powder coatings,” he added. “Automotive and Agricultural, Construction and Earthmoving equipment (ACE) are two other markets in which we see strong potential for growth. While powder has been a part of these markets historically, we’re finding businesses in these segments becoming more confident in the durability and performance of powder, using it on more parts and larger surfaces, including priming the exterior of vehicles.”

New Products

Sherwin-Williams recently launched POWDURA 4000 Super Durable Polyester Powder TGIC-free line of products, for metal building product OEMs and job shops needing to provide AAMA 2604 level of performance. They are designed to address resistance to abrasion, impact, scuffing and scratching, and deliver a finish with long-term durability for a broad range of architectural applications Most popular colors are available in stock, and available in 48 hours.

“It has long been recognized that although super-durable polyester TGICs are very robust systems, there are limitations in their flexibility, especially at higher film thicknesses or in multi-layer scenarios,” said McLeish. “To overcome this gap, Sherwin-Williams has developed a line of flexible super-durable TGIC coatings that will be launching in 2018. These coatings are formulated to have great flexibility at those higher film builds and in multi-coat applications, without sacrificing the appearance and durability characteristics our customers have come to expect from our products. We also continue to be excited about the acceleration of our One Cure systems.”

In January 2017, Axalta launched Alesta Lync, a Dry-on-Dry (DOD) powder coating application system with an energy-efficient process, excellent edge corrosion protection and the ability to provide two paint layers with only one cure cycle. The result is a reduction of process time, carbon output and capital investment while increasing productivity. This year Axalta also launched Nap-Gard 7-0015 internal pipe coatings, a good option for customers who need a flexible coating that provides corrosion protection in severe downhole environments up to 105°C (221°F) and Alesta non-slip powder coatings, which hold up to heavy traffic and harsh chemicals to provide an excellent solution for hazardous slip-prone areas on heavy duty equipment and platforms. Other notable additions have been its next generation powder coatings for automotive coil springs, allowing enhanced chip stone resistance in a single coat application, and a string of new Plascoat thermoplastic technologies designed to protect substrates like battery trays, park furniture, and the undercarriages of military vehicles in the harshest of environments.

“In addition to new products, Axalta introduced the ICONICA collection in Europe, an assortment of 40 new metallic colors from our Alesta Super Durable powder coatings portfolio that represent modern dynamics of nature and humanity,” said Cash. “The ICONICA launch was synchronized with the world’s leading furniture and design fair in Milan, and visitors were encouraged to interact with and explore the outdoor installation of 40 colors under constantly changing light.”

Cash said that Axalta has a full pipeline of new technologies for a wide array of markets set to launch in 2018. “We remain heavily focused on developing powder coatings to both make a difference in our customers’ businesses and lead the market in producing cutting edge technology,” he said. “For instance, we’ve invested heavily into our new generation of bonded metallics, which will be an exciting addition for us in the first quarter of next year. We also expect to launch powder coatings that can be applied successfully to plastic and fiberglass composites, powder products with leading crevice coverage properties for extreme faraday cage challenges, a new range of powder products for electrical wire encapsulation, and the next generation Ultra Durable architectural product line for AAMA 2605 applications.”

Axalta also plans to continue to leverage popular technologies and expand them globally, such as working with its manufacturing facilities in North America and China to produce the ICONICA collection and rolling out Alesta ZeroZinc Primers globally. “With the cost of zinc on the rise, we’ve seen increased demand in these primers, which provide performance, cost and environmental benefits,” Cash said.

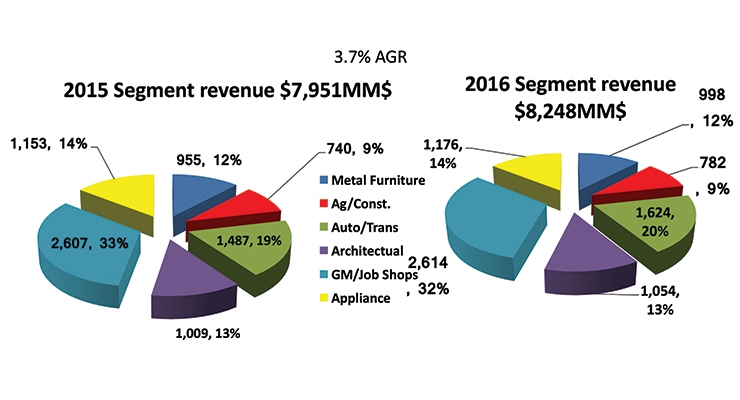

• General Metals/Job Shops remains the largest at $2,614M (32% SOM) in 2016, moving from $2,607M (33% SOM) in 2015;

• Automotive/Transportation is second at $1,624M (20% SOM) in 2016 & $1,487M in 2015 (19% SOM);

• Appliance is third at $1,176 in 2016 from $1,153M in 2015 (14% SOM);

• Architectural is fourth at $1,054M (13% SOM) in 2016 moving from $1,009M (13% SOM) in 2015;

• Metal Furniture is fifth with $998M in 2016 (13% SOM) moving up from $955M (12% SOM) in 2015;

• Agriculture/Construction sixth at $782M (10% SOM) in 2016 from $740M (9% SOM in 2015).

Architects, designers and developers have an exciting new source of inspiration to draw from following the launch of Collection Futura 2018-2021 by AkzoNobel’s Interpon powder coatings brand.

Full of the latest material and design trends, the collection - which is updated every four years - features an extensive range of highly durable and sustainable colors and finishes developed together with trend experts PeclersParis. It is based on several globally-identified trends for 2018-2021: Glam City, Time Out, Treasured Light and Wild Nature.

“Our color expertise and continued development of durable and sustainable solutions drives the creation of our Collection Futura,” explained Jean-Paul Moonen, AkzoNobel’s Powder Coatings Global Segment for Architecture. “The new collection includes a range of special finishes for use on exterior architectural metal components; products which are innovative, sustainable and always on trend.”

Each theme in the collection includes a unique range of colors, textures and effects that reflect the design and societal trends seen throughout the world. Innovation is also highly visible through two completely new finishes: silky texture and cotton.

Glam City includes modernist influences and baroque trends with intense, dark tones centered on reds, blues and greens. Time Out provides inspiration for soothing living spaces, with light tones based on colored whites and soft neutrals. Treasured Light offers sensual and more refined versions of metallic brilliance including brass, pink gold, pale copper and silver. Wild Nature explores more primitive, wild expressions of nature and features earthy browns, peaty khakis, anthracite greys and charcoal blacks.

Continued Moonen: “The new range of finishes will enable customers to achieve just the right effect in any environment while helping them contribute to the future of green building and sustainable development.” He added that the company’s Interpon powder coatings have achieved a third party Environmental Product Declaration (EPD) certification, which includes a lifecycle analysis of the raw materials used in the product itself, the manufacture of the product, its shipment and application.

It’s now 20 years since AkzoNobel launched the first special finishes collection for the powder coatings market worldwide. This is also the 15th year that the company has worked with Peclers to create a new trend collection for architects and designers as the global leader in powder coatings. In addition, AkzoNobel was the first powder coatings producer to launch the fine texture Sablé finishes, which have since become a major success in the powder coatings industry.

According to Chemark Consulting Group, powder coatings continue to take small meaningful SOM (share-of-the-market) chunks of the global coatings market segment real-estate. While aggregating all types of global coatings together, it grew from $125.5 million in sales revenue in 2015 to $126.5 million in 2016, only a 1.1 percent AGR. Conversely, powder coatings increased its SOM by 1 percent (from 6 percent in 2015 to 7 percent in 2016) and grew at 3.7 times the remainder of the coatings industry rates, at 3.9 percent.

According to Chemark analysts, powder coatings 2015 revenue at $7,951MM in 2015 grew at 3.7 percent to $8,248MM in 2016.

Powder coatings manufacturers Coatings World spoke with reported growth for 2017.

“The powder coatings market has continued to see substantial growth in 2017,” said Michael Cash, president, Industrial Coatings, Axalta Coating Systems. “We attribute this to a strong global economy and the ongoing desire to use the most sustainable and environmentally safe coating solutions. Continued advancements in technology have increased customer confidence in powder coatings, as they prove competitive to liquid solutions in color, design and durability, as well cost of application.”

“Powder coatings comprises a meaningful part of Axalta’s overall business and has proven to be one of our fastest growing segments,” Cash added. “Our sales growth in powder has remained at around twice the market rate consistently over the past four years. This year we’ve had the privilege of supplying powder coatings for monumental, global projects such as the 2016 Rio Olympic and Paralympic torches and the sound barriers installed on Shanghai’s new Metro Line 17.”

Sherwin-Williams saw continued demand for powder coatings globally in 2017 with growth levels above GDP, and expect that this trend will continue throughout 2018. “This demand is in part driven by all the advantages that powder coatings can offer to the finishing marketplace,” said Tabitha McLeish, global marketing director-Powder, General Industrial Coatings, The Sherwin-Williams Company. “As customers continue to push the capability envelope on improved appearance of finishes; the ability to cure at lower temperatures or at much faster cure rates; extended durability for color, gloss and corrosion; thinner films; and greater metallic color space, powder coatings continue to step up to meet the challenge.”

Powder Vs. Liquid

Powder coatings often have an advantage over liquid for a number of reasons.

“In suitable applications, powders provide excellent coverage, especially on corrosion-vulnerable edges,” said McLeish. “They also can deliver higher film thicknesses, up to 99 percent of powders can be recycled or reclaimed and the ability to oven cure induces the chemical reaction that provides a smooth finish.”

“Powder coatings are traditionally applied at a lower cost and are better for the environment, emitting zero or nearly zero volatile organic compounds (VOC),” said Cash. “Overspray can be recycled, eliminating product waste in contrast to liquid waste which can be more energy intensive to recycle and/or dispose of. Powder also has some aesthetic advantages, such as specialty effects like textures, veins and hammertones being easier to achieve than with other coating processes.”

Chemark reports that Asia-Pacific region continues to dominate in size at 43 percent SOM in 2015 and moved up a point to 44 percent SOM a year later in 2016. Western Europe follows at 25 percent for both years, with North America third but losing a SOM point at 16 percent in 2016, down from 17 percent in 2015. The remaining regions combine for a total of 14 percent in 2015 and remaining at 14 percent in 2016.

According to McLeish the heavy equipment market has been strong in both Asia and South America due to the comeback of the construction market in Asia and a stronger agricultural equipment market in South America. “Growth in these regions is expected to continue,” she continued. “Although the military market had been experiencing flat growth, that market is beginning to rebound and some nice growth is anticipated. The U.S. Department of Defense budget increases under the new administration are resulting in contract awards specific to asset protection programs requiring paint for durability and corrosion resistance. Environmental compliance will drive continued powder growth.”

Cash noted that he sees North America following the trend in Europe and China of using more powder coatings in the architectural extrusion market. “For example, in Philadelphia we’ve been constructing our Global Innovation Center using Axalta products throughout and have found, whether it be in extrusions for the building, windows and doors, or lab furniture, that it’s logistically and economically beneficial to coat most of the building components with our powder coatings,” he added. “Automotive and Agricultural, Construction and Earthmoving equipment (ACE) are two other markets in which we see strong potential for growth. While powder has been a part of these markets historically, we’re finding businesses in these segments becoming more confident in the durability and performance of powder, using it on more parts and larger surfaces, including priming the exterior of vehicles.”

New Products

Sherwin-Williams recently launched POWDURA 4000 Super Durable Polyester Powder TGIC-free line of products, for metal building product OEMs and job shops needing to provide AAMA 2604 level of performance. They are designed to address resistance to abrasion, impact, scuffing and scratching, and deliver a finish with long-term durability for a broad range of architectural applications Most popular colors are available in stock, and available in 48 hours.

“It has long been recognized that although super-durable polyester TGICs are very robust systems, there are limitations in their flexibility, especially at higher film thicknesses or in multi-layer scenarios,” said McLeish. “To overcome this gap, Sherwin-Williams has developed a line of flexible super-durable TGIC coatings that will be launching in 2018. These coatings are formulated to have great flexibility at those higher film builds and in multi-coat applications, without sacrificing the appearance and durability characteristics our customers have come to expect from our products. We also continue to be excited about the acceleration of our One Cure systems.”

In January 2017, Axalta launched Alesta Lync, a Dry-on-Dry (DOD) powder coating application system with an energy-efficient process, excellent edge corrosion protection and the ability to provide two paint layers with only one cure cycle. The result is a reduction of process time, carbon output and capital investment while increasing productivity. This year Axalta also launched Nap-Gard 7-0015 internal pipe coatings, a good option for customers who need a flexible coating that provides corrosion protection in severe downhole environments up to 105°C (221°F) and Alesta non-slip powder coatings, which hold up to heavy traffic and harsh chemicals to provide an excellent solution for hazardous slip-prone areas on heavy duty equipment and platforms. Other notable additions have been its next generation powder coatings for automotive coil springs, allowing enhanced chip stone resistance in a single coat application, and a string of new Plascoat thermoplastic technologies designed to protect substrates like battery trays, park furniture, and the undercarriages of military vehicles in the harshest of environments.

“In addition to new products, Axalta introduced the ICONICA collection in Europe, an assortment of 40 new metallic colors from our Alesta Super Durable powder coatings portfolio that represent modern dynamics of nature and humanity,” said Cash. “The ICONICA launch was synchronized with the world’s leading furniture and design fair in Milan, and visitors were encouraged to interact with and explore the outdoor installation of 40 colors under constantly changing light.”

Cash said that Axalta has a full pipeline of new technologies for a wide array of markets set to launch in 2018. “We remain heavily focused on developing powder coatings to both make a difference in our customers’ businesses and lead the market in producing cutting edge technology,” he said. “For instance, we’ve invested heavily into our new generation of bonded metallics, which will be an exciting addition for us in the first quarter of next year. We also expect to launch powder coatings that can be applied successfully to plastic and fiberglass composites, powder products with leading crevice coverage properties for extreme faraday cage challenges, a new range of powder products for electrical wire encapsulation, and the next generation Ultra Durable architectural product line for AAMA 2605 applications.”

Axalta also plans to continue to leverage popular technologies and expand them globally, such as working with its manufacturing facilities in North America and China to produce the ICONICA collection and rolling out Alesta ZeroZinc Primers globally. “With the cost of zinc on the rise, we’ve seen increased demand in these primers, which provide performance, cost and environmental benefits,” Cash said.

• General Metals/Job Shops remains the largest at $2,614M (32% SOM) in 2016, moving from $2,607M (33% SOM) in 2015;

• Automotive/Transportation is second at $1,624M (20% SOM) in 2016 & $1,487M in 2015 (19% SOM);

• Appliance is third at $1,176 in 2016 from $1,153M in 2015 (14% SOM);

• Architectural is fourth at $1,054M (13% SOM) in 2016 moving from $1,009M (13% SOM) in 2015;

• Metal Furniture is fifth with $998M in 2016 (13% SOM) moving up from $955M (12% SOM) in 2015;

• Agriculture/Construction sixth at $782M (10% SOM) in 2016 from $740M (9% SOM in 2015).

Architects, designers and developers have an exciting new source of inspiration to draw from following the launch of Collection Futura 2018-2021 by AkzoNobel’s Interpon powder coatings brand.

Full of the latest material and design trends, the collection - which is updated every four years - features an extensive range of highly durable and sustainable colors and finishes developed together with trend experts PeclersParis. It is based on several globally-identified trends for 2018-2021: Glam City, Time Out, Treasured Light and Wild Nature.

“Our color expertise and continued development of durable and sustainable solutions drives the creation of our Collection Futura,” explained Jean-Paul Moonen, AkzoNobel’s Powder Coatings Global Segment for Architecture. “The new collection includes a range of special finishes for use on exterior architectural metal components; products which are innovative, sustainable and always on trend.”

Each theme in the collection includes a unique range of colors, textures and effects that reflect the design and societal trends seen throughout the world. Innovation is also highly visible through two completely new finishes: silky texture and cotton.

Glam City includes modernist influences and baroque trends with intense, dark tones centered on reds, blues and greens. Time Out provides inspiration for soothing living spaces, with light tones based on colored whites and soft neutrals. Treasured Light offers sensual and more refined versions of metallic brilliance including brass, pink gold, pale copper and silver. Wild Nature explores more primitive, wild expressions of nature and features earthy browns, peaty khakis, anthracite greys and charcoal blacks.

Continued Moonen: “The new range of finishes will enable customers to achieve just the right effect in any environment while helping them contribute to the future of green building and sustainable development.” He added that the company’s Interpon powder coatings have achieved a third party Environmental Product Declaration (EPD) certification, which includes a lifecycle analysis of the raw materials used in the product itself, the manufacture of the product, its shipment and application.

It’s now 20 years since AkzoNobel launched the first special finishes collection for the powder coatings market worldwide. This is also the 15th year that the company has worked with Peclers to create a new trend collection for architects and designers as the global leader in powder coatings. In addition, AkzoNobel was the first powder coatings producer to launch the fine texture Sablé finishes, which have since become a major success in the powder coatings industry.