Ramesh Tripathi, Chugoku Paints (India) Pvt Ltd, Mumbai10.10.16

Marine coating systems are applied to ships and offshore structures both in sea and fresh water environments. They serve the dual purpose of protecting the structure from deterioration and keeping the ships looking good. The world merchant fleet is comprised of bulk carriers, tankers, container ships, cargo ships, and passenger and cruise ships, among others.

Marine coatings have specific functional properties that provide superior corrosion protection to the surfaces on which they are applied. The coatings protect submerged materials such as vessels, ships, or yachts from sea water. Marine coatings also protect materials from corrosion and abrasion. The application of such coatings improves the durability and overall performance of the vessel.

The latest survey report on the global antifouling paint market, published by Markets and Markets, projects the market to grow from U.S. $5.61 billion in 2015 to U.S. $9.22 billion by 2021 at a CAGR (Compound Annual Growth Rate) of 8.6 percent between 2016 and 2021. High demand for antifouling coatings from the shipping industry is expected to drive the growth of the market in the near future, the report states.

Asia-Pacific dominates the global distribution of marine coatings for both new shipbuilding and repairs. China is fast becoming the world’s largest shipbuilding nation and has set a goal of becoming number one in the industry by 2017.

As per record from ‘The Shipbuilders Association of Japan’ the New Shipbuilding share for 2015 is: Japan 19.2%, South Korea 34.4%, China 37.2%, Europe 1.4%, and the rest of the world 7.7%.

High demand for marine coatings in Asia-Pacific, especially due to the emergence of China as a major player in the shipbuilding industry, is driving the marine coatings market in the region.

Need for fuel-saving and low emission coatings are factors that have driven the growth of the marine coatings market over the past few years. Growth in the shipbuilding industry in India, Vietnam and the Philippines is expected to provide large opportunities for players in the marine coatings market during the forecast period.

The global marine coatings market is heavily consolidated, with 80% of the market shared by five companies—AkzoNobel (through its International Paint business), Chugoku Marine Paints, Hempel’s Marine Paints, Jotun and PPG.

What Are Antifouling Coatings?

Antifouling coatings are specialized paints applied to the ship’s hull to slow the marine growth on the underwater area which can affect the vessels performance and durability. In addition to preventing marine growth, the hull coating can also act as a barrier against hull corrosion that will degrade and weaken the metal. It also improves the flow of water passing the hull of a fishing vessel or high-performance racing yacht.

Prevention of Marine Growth (Biofouling)

Antifouling paint, applied to the underwater hull of ships, discourages or prevents the growth of organisms that attach to the hull. Its self-polishing resin and biocide, such as cuprous oxide along with a booster biocide, help to prevent biofouling organisms.

A self-polishing copolymer (SPC) antifouling paint will release biocide at a nearly constant rate throughout its life. The diffusion of the biocide on the hull surface is primarily due to a chemical reaction between the paint and seawater. The self-polishing mechanism of an antifouling paint film ensures a consistent renewal of paint film and release of biocide on the surface to prevent settlement and attachment of biofoulants.

The self-polishing activity is very dependent on the speed and activities of the vessels. Based on various studies, the polishing rate of anti-fouling paint reduces almost by half when it is stationary as compared to when the vessel travels at 14 knots. Hence, the duration of the vessel staying stationary will enable the colonizing of micro- and macrofouling as explained below.

Mechanism of Marine Growth (Biofouling)

Marine biofouling can be defined as the unwanted deposition or accumulation of microorganisms, plants and animals on the ship hull immersed in sea water. Fouling of the ship’s hull will result in speed reduction, increased fuel consumption, loss in time and money and a higher frequency of dry-dockings.

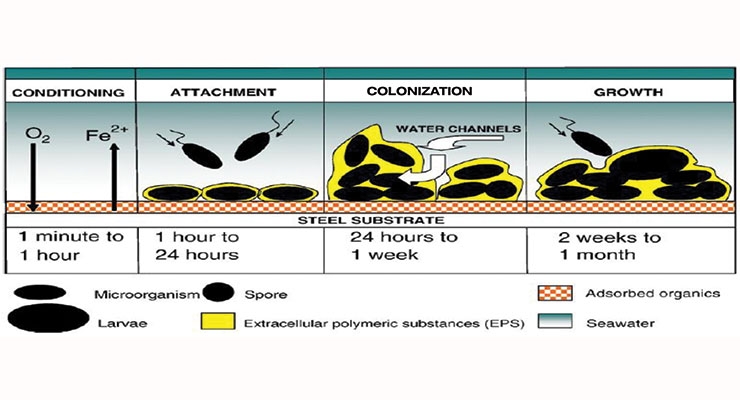

The process of biological fouling is often grouped into key growth stages as shown in Figure 1 which illustrates the accumulation of adsorbed organics, settlement and growth of bacteria creating a biofilm matrix and subsequent succession of micro- and macrofoulers.

Biofouling consists of two main components: microfouling and macrofouling. Microfouling refers to the formation of biofilm and adhesion to the surface, and macrofouling refers to the attachment of organisms such as barnacles, diatoms and sea weed to produce a fouling community. The growing bacteria and the chemicals they secrete make up microfouling, also referred to as ‘slime’, which develops within hours of an object’s immersion in water. Within a few days, macrofouling develops as unicellular eukaryotes, such as protozoa and diatoms, that colonize the surface. Multicellular eukaryotes begin colonizing the surface within several weeks and include settlement of meroplankton larvae and algal spores.

New Technology Growth

Marine environment is a harsh environment in terms of corrosion and biofouling. Biofouling generates huge operational losses for the shipping Industry. A high degree of fouling on the ship’s hull significantly increases drag, reducing the overall hydrodynamic performance of the vessel and increasing the fuel consumption. Due to these reasons, it is in the best interest of the ship owners to use high-performance coatings that prevent corrosion and antifouling growth on the ship’s hull.

Reduced fuel consumption and increasingly stringent environmental regulations have prompted the development of new antifouling technologies. Marine coatings manufacturers are generally cautious in adopting new technologies. However, increasingly stringent environmental legislation, paralleled by customer preference for more eco-friendly products, is pushing innovation in the market.

The need to lower fuel consumption and to reduce CO2 emission has become a strong driving force for paint companies to develop new technologically-advanced antifouling coatings for ship’s hulls which reduces the fuel consumption.

Foul-release technology, which also results in substantial fuel savings, is particularly useful for large cargo ships, which consume a lot of fuel. Many companies are investing time and money in developing eco-friendly products such as low friction coatings, metal-free antifouling coatings, etc. Most recent participants now offer silicone- or fluororesin-based foul-release products.

Regulations Force New Developments

The present working principle for most of the marine paint systems is based on a slow release of toxins (self-polishing coatings). Although the antifouling performance of such systems is excellent, the amount of toxin released per ship may be quite substantial. The impact of such toxins on nature can be detrimental. Because of this impact, the use of organotins, such as tributyltin (TBT), on ship hulls was completely banned in 2001. In addition, the use of other toxins in antifouling coatings is restricted by law.

Although the use of copper-based paints is not yet prohibited it may be banned in the near future. Recently, the use of copper-based coatings for recreational boats has been banned in the ports of San Diego and Washington. This drives both science and industry to evaluate new types of antifouling mechanisms.

Alternatives to Self-Polishing Coatings

The following systems are commonly suggested and are also applied as alternatives to self-polishing coatings. Hydrophilic antifouling coatings prevent or slow down adherence of marine organisms to ship hulls. (The latest solutions that are provided by a marine coating manufacturer formulates anti-fouling paint based on hydrogel technology which is comprised of a network of advanced polymer chains that absorb high amounts of water to create a water-like boundary layer. This water-like layer misguides the fouling organisms into believing that the hull is a liquid and solid surface and this minimizes protein and bacterial adhesion to the hull.)

• Low energy, hydrophobic foul-release coatings facilitate an easy release of marine organisms.

Traditional fouling release coatings consist of a silicone elastomer (PDMS) which relies on low surface tension (hydrophobic) and low modulus of elasticity, usually with a good initial foul-free performance. Over time, the coatings ability to self-clean is lowered, which results in a higher hull skin friction. The technology behind the third generation fouling release coatings is a unique blend of silicone polymers which maintains a more hydrophobic surface, with fouling release performance that lasts. The foul-free period is longer, and required speed for self-cleaning is lower. This results in a lower hull skin friction over time with potentially lower fuel consumption.

• Enzyme-based coating systems.

Current antifouling technologies for ship hulls are based on metals such as cuprous oxide and co-biocides like zinc pyrithione. Due to the adverse effect of these biocides on the environment, enzyme-based antifouling paints are proposed as a bio-based, non-accumulating alternative. Scientists tested a hydrogen peroxide-producing system composed of hexose oxidase, glucoamylase and starch for the chemical and physical functionalities necessary for successful incorporation into a marine coating. The activity and stability of the enzymes in seawater was evaluated at different temperatures, and paint compatibility was assessed by measuring the distribution and activity of the enzymes incorporated into prototype coating formulations. The scientists used a biomimetic encapsulation procedure for HOX through polyethylenimine-templated silica co-precipitation. Silica co-precipitation significantly improved the stability and performance of the antifouling system in marine-like conditions.

• New biocide free, two-component, fouling release coating.

Non-stick fouling release coatings are based on a technology which prevents the adhesion of fouling organisms by providing a low-friction, ultra-smooth surface on which organisms have great difficulty in adhering. The coatings do not inhibit the fouling settlement, but provide self-cleaning when sailing at a certain speed at a certain activity, typically minimally 15 knots at minimum 75 percent of the time. Fouling release coatings have their origin in the desire for a biocide-free system and have been in existence for 30 years. On these types of coatings fouling is not prevented from settling, as in the case of traditional antifouling, but in practice the bond between the fouling organisms and the coating surface is so weak that it breaks by the weight of the organism itself or by the water pressure and current to which it is exposed.

• Copper-Free Antifouling coating

CuO is a still a very effective biocide but it requires a high concentration to give fully effective protection against most types of marine fouling. Paints that contain less copper metal, or use less powerful ingredients such as copper thiocyanate, often contain extra biocides such as zinc pyrithione or organic algaecides to cope with slime and weed growth. It is these organic boosters that are currently causing a stir, as some people think they could cause similar problems to TBT.

One of the latest biocides to be authorized is Selektope (generic name medetomidine), made by the pharmaceutical giant AstraZeneca. Instead of killing off marine growth, it is said to temporarily stimulate the octopamine receptor in the larvae of molluscs, causing them to be harmlessly repelled from the hull. Various research has apparently proved that it works at extremely low concentration levels (3 g/L) in any paint, and needs no other biocide for a barnacle-free hull. Sadly it’s not as effective on weeds, so paint formulations will also have to contain approved algaecides to be effective.

• Self-adhesive /fouling-release coatings.

The ‘eSHaRk’ (eco-friendly Ship Hull film system with fouling Release and fuel-saving properties) project aims to bring to the market a fouling-protection technology which not only maintains the current state-of-the-art fouling-protection standards, but is superior to existing paint-based solutions in terms of eco-friendliness, ease of application, robustness and drag-reduction effects, all of which will lead to fuel savings and the reduction of GHG (greenhouse gas) emissions.

The system incorporates a fine-tuned fouling-release system based on PPG’s 100% silicone binder technology and a self-adhesive film designed by MACtac for underwater use. As part of the ‘eSHaRk’ project, new, robotized application technology is being developed by VertiDrive that will be used to automate application of the film on large commercial vessels. Furthermore, the surface morphology of the film will be optimized to enhance drag-reduction, fuel-savings and emission-reduction benefits to previously unattainable levels.

• Nano antifouling coating

A number of manufacturers have come up with some sensible and effective alternative coatings, but none of them has solved the problem completely. But some interesting new products are on trial at the moment, which could well come to fruition within the next decade.

Among these are Teflon- and silicone-based nanotech coatings, using technology already found in marine gel coat polish. Cornwall-based Nanotech Marine is working on a self-cleaning nanotech antifoul and the first three-year test results look promising. It’s only intended for motorboats at the moment, but the company is looking into ways of applying the same principles for sailing boats.

Nanotech Marine’s antifoul is a silicone-based product, said to create a surface so slippery (at a molecular level) that no weed or mollusc can get a grip on the hull.

Research has shown it does indeed work, but only on boats capable of high speed (10 knots or more), which are used regularly, as the coating relies on the boat’s motion through the water to wash off biofouling. They’re not so effective for a boat left on a mooring or in a marina for weeks on end, so even if one has a fast yacht, a nanotech coating may have to be used in conjunction with another product, such as an ‘ultrasonic’ bio-deterrent system.

Conclusion

Companies are investing a lot in research and development to expand the efficiency of antifouling coatings which, in turn, is expected to increase the demand from end-users. Technology advancement worldwide is one of the trends expected to add to the growth of the global antifouling coatings market.

Increased demand for oil and gas, increasing population and urbanization are drivers for the growth of the antifouling coatings market. These are also widely used for the protection of structural infrastructure and machinery in rigs. One of the major challenges faced by the antifouling coatings market is predictable decline in the shipbuilding industry. The market has also been witnessing the growing consumer preference for eco-friendly products due to which strict environmental regulations have been imposed that pose a challenge to the growth of this market.

Marine coatings have specific functional properties that provide superior corrosion protection to the surfaces on which they are applied. The coatings protect submerged materials such as vessels, ships, or yachts from sea water. Marine coatings also protect materials from corrosion and abrasion. The application of such coatings improves the durability and overall performance of the vessel.

The latest survey report on the global antifouling paint market, published by Markets and Markets, projects the market to grow from U.S. $5.61 billion in 2015 to U.S. $9.22 billion by 2021 at a CAGR (Compound Annual Growth Rate) of 8.6 percent between 2016 and 2021. High demand for antifouling coatings from the shipping industry is expected to drive the growth of the market in the near future, the report states.

Asia-Pacific dominates the global distribution of marine coatings for both new shipbuilding and repairs. China is fast becoming the world’s largest shipbuilding nation and has set a goal of becoming number one in the industry by 2017.

As per record from ‘The Shipbuilders Association of Japan’ the New Shipbuilding share for 2015 is: Japan 19.2%, South Korea 34.4%, China 37.2%, Europe 1.4%, and the rest of the world 7.7%.

High demand for marine coatings in Asia-Pacific, especially due to the emergence of China as a major player in the shipbuilding industry, is driving the marine coatings market in the region.

Need for fuel-saving and low emission coatings are factors that have driven the growth of the marine coatings market over the past few years. Growth in the shipbuilding industry in India, Vietnam and the Philippines is expected to provide large opportunities for players in the marine coatings market during the forecast period.

The global marine coatings market is heavily consolidated, with 80% of the market shared by five companies—AkzoNobel (through its International Paint business), Chugoku Marine Paints, Hempel’s Marine Paints, Jotun and PPG.

What Are Antifouling Coatings?

Antifouling coatings are specialized paints applied to the ship’s hull to slow the marine growth on the underwater area which can affect the vessels performance and durability. In addition to preventing marine growth, the hull coating can also act as a barrier against hull corrosion that will degrade and weaken the metal. It also improves the flow of water passing the hull of a fishing vessel or high-performance racing yacht.

Prevention of Marine Growth (Biofouling)

Antifouling paint, applied to the underwater hull of ships, discourages or prevents the growth of organisms that attach to the hull. Its self-polishing resin and biocide, such as cuprous oxide along with a booster biocide, help to prevent biofouling organisms.

A self-polishing copolymer (SPC) antifouling paint will release biocide at a nearly constant rate throughout its life. The diffusion of the biocide on the hull surface is primarily due to a chemical reaction between the paint and seawater. The self-polishing mechanism of an antifouling paint film ensures a consistent renewal of paint film and release of biocide on the surface to prevent settlement and attachment of biofoulants.

The self-polishing activity is very dependent on the speed and activities of the vessels. Based on various studies, the polishing rate of anti-fouling paint reduces almost by half when it is stationary as compared to when the vessel travels at 14 knots. Hence, the duration of the vessel staying stationary will enable the colonizing of micro- and macrofouling as explained below.

Mechanism of Marine Growth (Biofouling)

Marine biofouling can be defined as the unwanted deposition or accumulation of microorganisms, plants and animals on the ship hull immersed in sea water. Fouling of the ship’s hull will result in speed reduction, increased fuel consumption, loss in time and money and a higher frequency of dry-dockings.

The process of biological fouling is often grouped into key growth stages as shown in Figure 1 which illustrates the accumulation of adsorbed organics, settlement and growth of bacteria creating a biofilm matrix and subsequent succession of micro- and macrofoulers.

Biofouling consists of two main components: microfouling and macrofouling. Microfouling refers to the formation of biofilm and adhesion to the surface, and macrofouling refers to the attachment of organisms such as barnacles, diatoms and sea weed to produce a fouling community. The growing bacteria and the chemicals they secrete make up microfouling, also referred to as ‘slime’, which develops within hours of an object’s immersion in water. Within a few days, macrofouling develops as unicellular eukaryotes, such as protozoa and diatoms, that colonize the surface. Multicellular eukaryotes begin colonizing the surface within several weeks and include settlement of meroplankton larvae and algal spores.

New Technology Growth

Marine environment is a harsh environment in terms of corrosion and biofouling. Biofouling generates huge operational losses for the shipping Industry. A high degree of fouling on the ship’s hull significantly increases drag, reducing the overall hydrodynamic performance of the vessel and increasing the fuel consumption. Due to these reasons, it is in the best interest of the ship owners to use high-performance coatings that prevent corrosion and antifouling growth on the ship’s hull.

Reduced fuel consumption and increasingly stringent environmental regulations have prompted the development of new antifouling technologies. Marine coatings manufacturers are generally cautious in adopting new technologies. However, increasingly stringent environmental legislation, paralleled by customer preference for more eco-friendly products, is pushing innovation in the market.

The need to lower fuel consumption and to reduce CO2 emission has become a strong driving force for paint companies to develop new technologically-advanced antifouling coatings for ship’s hulls which reduces the fuel consumption.

Foul-release technology, which also results in substantial fuel savings, is particularly useful for large cargo ships, which consume a lot of fuel. Many companies are investing time and money in developing eco-friendly products such as low friction coatings, metal-free antifouling coatings, etc. Most recent participants now offer silicone- or fluororesin-based foul-release products.

Regulations Force New Developments

The present working principle for most of the marine paint systems is based on a slow release of toxins (self-polishing coatings). Although the antifouling performance of such systems is excellent, the amount of toxin released per ship may be quite substantial. The impact of such toxins on nature can be detrimental. Because of this impact, the use of organotins, such as tributyltin (TBT), on ship hulls was completely banned in 2001. In addition, the use of other toxins in antifouling coatings is restricted by law.

Although the use of copper-based paints is not yet prohibited it may be banned in the near future. Recently, the use of copper-based coatings for recreational boats has been banned in the ports of San Diego and Washington. This drives both science and industry to evaluate new types of antifouling mechanisms.

Alternatives to Self-Polishing Coatings

The following systems are commonly suggested and are also applied as alternatives to self-polishing coatings. Hydrophilic antifouling coatings prevent or slow down adherence of marine organisms to ship hulls. (The latest solutions that are provided by a marine coating manufacturer formulates anti-fouling paint based on hydrogel technology which is comprised of a network of advanced polymer chains that absorb high amounts of water to create a water-like boundary layer. This water-like layer misguides the fouling organisms into believing that the hull is a liquid and solid surface and this minimizes protein and bacterial adhesion to the hull.)

• Low energy, hydrophobic foul-release coatings facilitate an easy release of marine organisms.

Traditional fouling release coatings consist of a silicone elastomer (PDMS) which relies on low surface tension (hydrophobic) and low modulus of elasticity, usually with a good initial foul-free performance. Over time, the coatings ability to self-clean is lowered, which results in a higher hull skin friction. The technology behind the third generation fouling release coatings is a unique blend of silicone polymers which maintains a more hydrophobic surface, with fouling release performance that lasts. The foul-free period is longer, and required speed for self-cleaning is lower. This results in a lower hull skin friction over time with potentially lower fuel consumption.

• Enzyme-based coating systems.

Current antifouling technologies for ship hulls are based on metals such as cuprous oxide and co-biocides like zinc pyrithione. Due to the adverse effect of these biocides on the environment, enzyme-based antifouling paints are proposed as a bio-based, non-accumulating alternative. Scientists tested a hydrogen peroxide-producing system composed of hexose oxidase, glucoamylase and starch for the chemical and physical functionalities necessary for successful incorporation into a marine coating. The activity and stability of the enzymes in seawater was evaluated at different temperatures, and paint compatibility was assessed by measuring the distribution and activity of the enzymes incorporated into prototype coating formulations. The scientists used a biomimetic encapsulation procedure for HOX through polyethylenimine-templated silica co-precipitation. Silica co-precipitation significantly improved the stability and performance of the antifouling system in marine-like conditions.

• New biocide free, two-component, fouling release coating.

Non-stick fouling release coatings are based on a technology which prevents the adhesion of fouling organisms by providing a low-friction, ultra-smooth surface on which organisms have great difficulty in adhering. The coatings do not inhibit the fouling settlement, but provide self-cleaning when sailing at a certain speed at a certain activity, typically minimally 15 knots at minimum 75 percent of the time. Fouling release coatings have their origin in the desire for a biocide-free system and have been in existence for 30 years. On these types of coatings fouling is not prevented from settling, as in the case of traditional antifouling, but in practice the bond between the fouling organisms and the coating surface is so weak that it breaks by the weight of the organism itself or by the water pressure and current to which it is exposed.

• Copper-Free Antifouling coating

CuO is a still a very effective biocide but it requires a high concentration to give fully effective protection against most types of marine fouling. Paints that contain less copper metal, or use less powerful ingredients such as copper thiocyanate, often contain extra biocides such as zinc pyrithione or organic algaecides to cope with slime and weed growth. It is these organic boosters that are currently causing a stir, as some people think they could cause similar problems to TBT.

One of the latest biocides to be authorized is Selektope (generic name medetomidine), made by the pharmaceutical giant AstraZeneca. Instead of killing off marine growth, it is said to temporarily stimulate the octopamine receptor in the larvae of molluscs, causing them to be harmlessly repelled from the hull. Various research has apparently proved that it works at extremely low concentration levels (3 g/L) in any paint, and needs no other biocide for a barnacle-free hull. Sadly it’s not as effective on weeds, so paint formulations will also have to contain approved algaecides to be effective.

• Self-adhesive /fouling-release coatings.

The ‘eSHaRk’ (eco-friendly Ship Hull film system with fouling Release and fuel-saving properties) project aims to bring to the market a fouling-protection technology which not only maintains the current state-of-the-art fouling-protection standards, but is superior to existing paint-based solutions in terms of eco-friendliness, ease of application, robustness and drag-reduction effects, all of which will lead to fuel savings and the reduction of GHG (greenhouse gas) emissions.

The system incorporates a fine-tuned fouling-release system based on PPG’s 100% silicone binder technology and a self-adhesive film designed by MACtac for underwater use. As part of the ‘eSHaRk’ project, new, robotized application technology is being developed by VertiDrive that will be used to automate application of the film on large commercial vessels. Furthermore, the surface morphology of the film will be optimized to enhance drag-reduction, fuel-savings and emission-reduction benefits to previously unattainable levels.

• Nano antifouling coating

A number of manufacturers have come up with some sensible and effective alternative coatings, but none of them has solved the problem completely. But some interesting new products are on trial at the moment, which could well come to fruition within the next decade.

Among these are Teflon- and silicone-based nanotech coatings, using technology already found in marine gel coat polish. Cornwall-based Nanotech Marine is working on a self-cleaning nanotech antifoul and the first three-year test results look promising. It’s only intended for motorboats at the moment, but the company is looking into ways of applying the same principles for sailing boats.

Nanotech Marine’s antifoul is a silicone-based product, said to create a surface so slippery (at a molecular level) that no weed or mollusc can get a grip on the hull.

Research has shown it does indeed work, but only on boats capable of high speed (10 knots or more), which are used regularly, as the coating relies on the boat’s motion through the water to wash off biofouling. They’re not so effective for a boat left on a mooring or in a marina for weeks on end, so even if one has a fast yacht, a nanotech coating may have to be used in conjunction with another product, such as an ‘ultrasonic’ bio-deterrent system.

Conclusion

Companies are investing a lot in research and development to expand the efficiency of antifouling coatings which, in turn, is expected to increase the demand from end-users. Technology advancement worldwide is one of the trends expected to add to the growth of the global antifouling coatings market.

Increased demand for oil and gas, increasing population and urbanization are drivers for the growth of the antifouling coatings market. These are also widely used for the protection of structural infrastructure and machinery in rigs. One of the major challenges faced by the antifouling coatings market is predictable decline in the shipbuilding industry. The market has also been witnessing the growing consumer preference for eco-friendly products due to which strict environmental regulations have been imposed that pose a challenge to the growth of this market.