Shamrock Technologies Technical Service Group01.23.20

PTFE resin is made by the polymerization of TFE (tetrafluoroethylene monomer) to very high molecular weight (MW), in the millions. Low MW PTFE micro-powders are typically made by the degradation of such high MW PTFE resin.

Degradation may be affected by thermal or radiation-induced processes, where the backbone carbon-carbon bond is broken to form an active free radical. In such thermal or radiation-induced degradation processes, there is a random distribution of varying chain lengths, and some small percent of the molecules may be 8 carbons long.

One chemical property of the 8-carbon fluorinated molecule is that the reactive radical group can combine with oxygen and moisture in the air to form a terminal carboxylic acid group.

This group results in Per-Fluoro-Octanoic-Acid (PFOA). The concentration of PFOA in the process of making PTFE micro-powder may be in the range of parts per million.

The European Union has put forth a regulation[i], requiring a limitation of no more than 25 parts per billion (grams per thousand tons) of PFOA in PTFE micro-powder to take effect on July 4, 2020. To conform to this new REACH regulation, PTFE micro-powders need to be tested and, if necessary, treated to ensure PFOA content is less than 25 parts per billion.

As of this time, there is no globally accepted standard test method for measuring PFOA content in PTFE micro-powders, nor is there any indication as to how the regulation will be enforced. Shamrock has pro-actively adopted a method similar to 3M’s Standard Test Method (Edition 1.0, Nov 2016), based on the extraction of PTFE powders with methanol and the use of liquid chromatography-mass spectrometry (LC-MS) to determine the concentration of PFOA.

Shamrock’s internal Test Method, QSOP-202E[ii], has correlated well with test data (of the same powder samples) from external test centers to validate accuracy and precision. Scientists generally agree that an accepted test method is calibration with known standards whereby the results of the same samples in different labs are within experimental error.

With a validated Test Method, Shamrock established a fully dedicated PFOA Test Center with 2 LC-MS systems and started building the database of PFOA in its portfolio of PTFE-containing products. With statistically significant lot-verified data, Shamrock mapped out pathways to ensuring that its product lines are PFOA REACH Compliant (RC) on an industrial scale, product by product, lot by lot.

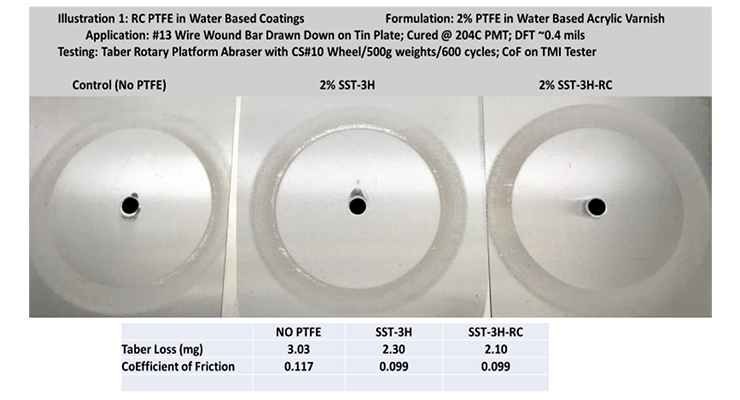

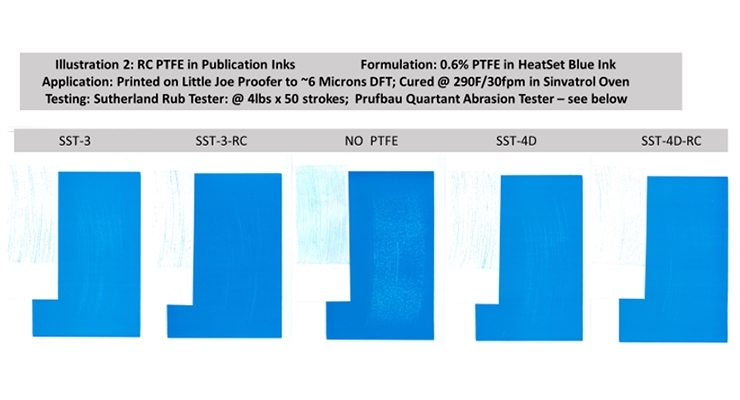

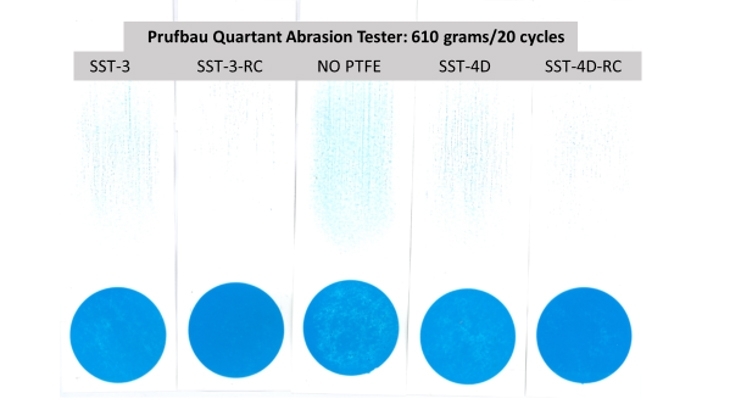

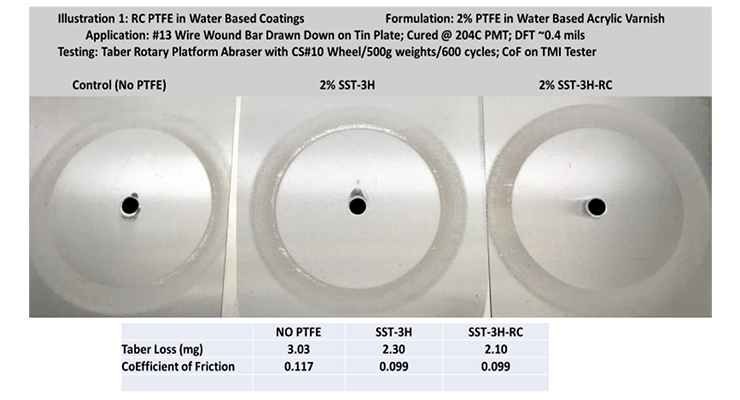

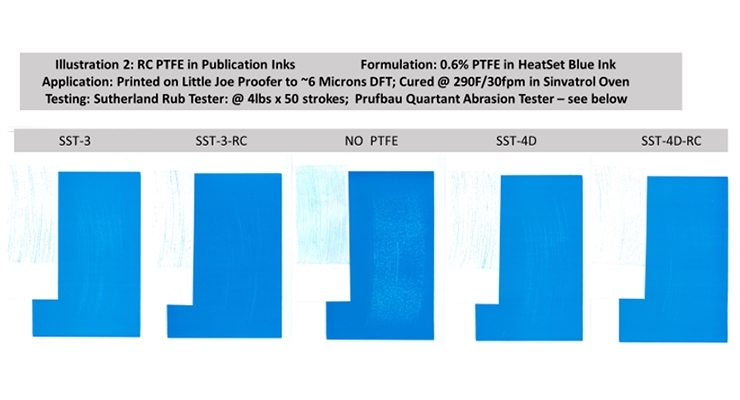

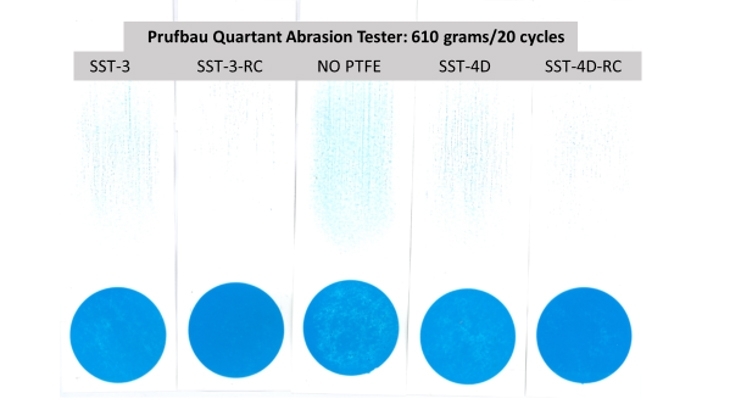

PTFE micro-powder products based on a controlled degradation process may be made with virgin or recycled based PTFE. In some applications, the recycled based PTFE micro-powder products out-perform virgin based products, and in others, the opposite. Different degrees of degradation seem to work better in some specific applications. Combinations of raw material type and varying degrees of degradation result in different pathways to achieve the desired RC product with specific performance similar to the original non-RC version. PTFE micro-powders are used in several industries for a wide range of properties, and in particular, for their superior ability to lower the surface coefficient of friction (slip) and to withstand rub, wear and abrasion in many coating and ink applications. The following are illustrations of how the RC PTFE micro-powders perform relative to the already established non-RC versions.

Taber Abrasion test comparison between REACH compliant PTFE and PTFE

Sutherland Rub Tester result comparison between REACH compliant PTFE and PTFE standard product

Test result comparing REACH Compliant PTFE and standard PTFE

As evident from the test data above, and with customer-validated production-based conversions across multiple industries, Shamrock has successfully transitioned the major products in our current PTFE micro-powder portfolio towards REACH Compliance, and are shipping these lot-verified RC products globally. However, given the global regulatory environment, Shamrock is pushing towards even more stringent standards: non-detectable (ND) level of PFOA in our PTFE-containing products, complemented by an expanded portfolio of non-PTFE Products that approach the same performance benefits in surface coatings and inks. Contact our Marketing REACH Compliance team to explore the possibilities at MRC@shamrocktechnologies.com.

[i] “ANNEX XVII TO REACH – Conditions of restriction” ECHA, 14 June. 2014, https://echa.europa.eu/documents/10162/7a04b630-e00a-a9c5-bc85-0de793f6643c

[ii] Chen, Bin. “QSOP – 202E.” Shamrock Technologies, 15 Jan. 2020, https://shamrocktechnologies.com/research/#QSOP202E

Degradation may be affected by thermal or radiation-induced processes, where the backbone carbon-carbon bond is broken to form an active free radical. In such thermal or radiation-induced degradation processes, there is a random distribution of varying chain lengths, and some small percent of the molecules may be 8 carbons long.

One chemical property of the 8-carbon fluorinated molecule is that the reactive radical group can combine with oxygen and moisture in the air to form a terminal carboxylic acid group.

This group results in Per-Fluoro-Octanoic-Acid (PFOA). The concentration of PFOA in the process of making PTFE micro-powder may be in the range of parts per million.

The European Union has put forth a regulation[i], requiring a limitation of no more than 25 parts per billion (grams per thousand tons) of PFOA in PTFE micro-powder to take effect on July 4, 2020. To conform to this new REACH regulation, PTFE micro-powders need to be tested and, if necessary, treated to ensure PFOA content is less than 25 parts per billion.

As of this time, there is no globally accepted standard test method for measuring PFOA content in PTFE micro-powders, nor is there any indication as to how the regulation will be enforced. Shamrock has pro-actively adopted a method similar to 3M’s Standard Test Method (Edition 1.0, Nov 2016), based on the extraction of PTFE powders with methanol and the use of liquid chromatography-mass spectrometry (LC-MS) to determine the concentration of PFOA.

Shamrock’s internal Test Method, QSOP-202E[ii], has correlated well with test data (of the same powder samples) from external test centers to validate accuracy and precision. Scientists generally agree that an accepted test method is calibration with known standards whereby the results of the same samples in different labs are within experimental error.

With a validated Test Method, Shamrock established a fully dedicated PFOA Test Center with 2 LC-MS systems and started building the database of PFOA in its portfolio of PTFE-containing products. With statistically significant lot-verified data, Shamrock mapped out pathways to ensuring that its product lines are PFOA REACH Compliant (RC) on an industrial scale, product by product, lot by lot.

PTFE micro-powder products based on a controlled degradation process may be made with virgin or recycled based PTFE. In some applications, the recycled based PTFE micro-powder products out-perform virgin based products, and in others, the opposite. Different degrees of degradation seem to work better in some specific applications. Combinations of raw material type and varying degrees of degradation result in different pathways to achieve the desired RC product with specific performance similar to the original non-RC version. PTFE micro-powders are used in several industries for a wide range of properties, and in particular, for their superior ability to lower the surface coefficient of friction (slip) and to withstand rub, wear and abrasion in many coating and ink applications. The following are illustrations of how the RC PTFE micro-powders perform relative to the already established non-RC versions.

Taber Abrasion test comparison between REACH compliant PTFE and PTFE

Sutherland Rub Tester result comparison between REACH compliant PTFE and PTFE standard product

Test result comparing REACH Compliant PTFE and standard PTFE

As evident from the test data above, and with customer-validated production-based conversions across multiple industries, Shamrock has successfully transitioned the major products in our current PTFE micro-powder portfolio towards REACH Compliance, and are shipping these lot-verified RC products globally. However, given the global regulatory environment, Shamrock is pushing towards even more stringent standards: non-detectable (ND) level of PFOA in our PTFE-containing products, complemented by an expanded portfolio of non-PTFE Products that approach the same performance benefits in surface coatings and inks. Contact our Marketing REACH Compliance team to explore the possibilities at MRC@shamrocktechnologies.com.

[i] “ANNEX XVII TO REACH – Conditions of restriction” ECHA, 14 June. 2014, https://echa.europa.eu/documents/10162/7a04b630-e00a-a9c5-bc85-0de793f6643c

[ii] Chen, Bin. “QSOP – 202E.” Shamrock Technologies, 15 Jan. 2020, https://shamrocktechnologies.com/research/#QSOP202E