PFASs consist of a fully (per) or partly (poly) fluorinated carbon chain connected to different functional groups. Based on the length of the fluorinated carbon chain, short and long chain PFASs can be distinguished. Long chains refers to:

• perfluorocarboxylic acids (PFCAs) with carbon chain lengths C8 and higher, including perfluorooctanoic acid (PFOA);

• perfluoroalkane sulfonic acids (PFSAs) with carbon chain lengths C6 and higher, including perfluorohexane sulfonic acid (PFHxS) and perfluorooctane sulfonate (PFOS); and

• precursors of these substances that may be produced or present in products.

(Source: The Organisation for Economic Co-operation and Development (OECD) https://www.oecd.org/chemicalsafety/portal-perfluorinated-chemicals/).

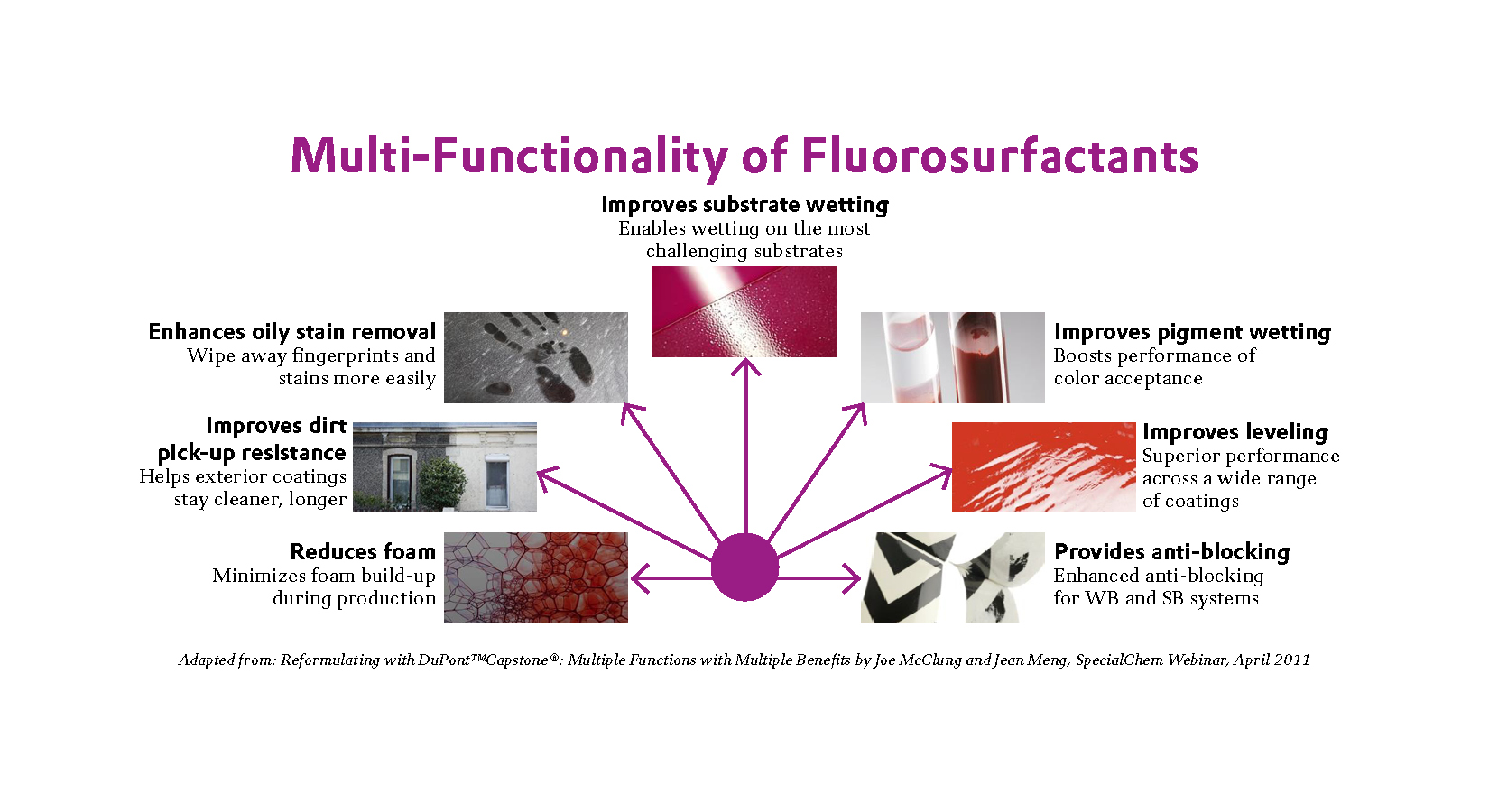

Fluorosurfacts are highly efficient at low additives doses and are effective for improved leveling and oleophobic effects, although they can be difficult to defoam. In the paint and coatings market fluorosurfactants are in used in variety of applications.

“They are used in many different types of coatings, including interior and exterior architectural coatings, wood coatings, flooring and industrial coatings for metal and plastics,” said Jim Reader, lead chemist at Evonik. “They are used as additives to help wetting of different surfaces, prevent surface defects such as craters, fish eyes and edge pull and to improve the surface appearance – flow and leveling, depth of Image – of the finished coating. They can also improve the stain resistance and water resistance of some coating formulations.”

According to information from the OECD, some of the unique physicochemical properties of per- and polyfluoroalkyl substances (PFASs), such as water-, oil- and grease-repellence and high thermal stability that popularized their widespread use are associated with environmental and human health concerns. Formulators are seeking alternatives to fluorosurfactants mainly for regulatory reasons or concerns about future regulation of these products due to environmental concerns.

Alternatives

“Formulators can look to use organo-modified siloxanes or organic (hydrocarbon) based additives as alternatives, although it may not be possible to find a single, drop-in alternative and additive combinations may be needed,” said Reader.

He noted that adjustments will need to be made.

“1:1 replacement of fluorosurfactants, especially with hydrocarbon based additives, is difficult and formulators will probably need to increase the additive dose to achieve the same performance,” said Reader. “Fluorosurfactants are often quite expensive, so this may not affect the overall pricing significantly but formulators will need to test that other coating properties are not affected. Fluorosurfactants are stable in a very wide range of temperatures and chemical environments so formulators will also need to confirm that the alternative products are stable in the coating environment. I have also noticed that defoamer performance can also sometimes be affected by changing these additives and these may also need reformulating.”

Here is a look at a number of alternatives to fluorosurfactants used as wetting agents and what they application they are best suited for.

• Acetylenic Diols - Control of defects like retraction, air entrapment and film formation

High speed applications like roll coat, spray and printing.

• Alkyl Polyethers - Cost effective performance.m Grind aids for particle dispersion and stabilization. O/W Emulsification.

• Polyether Siloxanes – Control of defects like leveling, craters and edge retraction.

• Silicone Gemini Surfactants - Control of defects like leveling, craters and edge retraction. Wetting very difficult surfaces.

• Sulfo-Succinates - Cost effective performance. Control of defects like retraction, craters and edge effects. Wetting very difficult surfaces.

• Thioethers - Control of defects like retraction, air entrapment plus aids film formation and coalescence. High speed applications.

• Alkane Diol - Control of defects like retraction, air entrapment plus aids film formation and coalescence. Effective foam control. High speed applications.