07.11.17

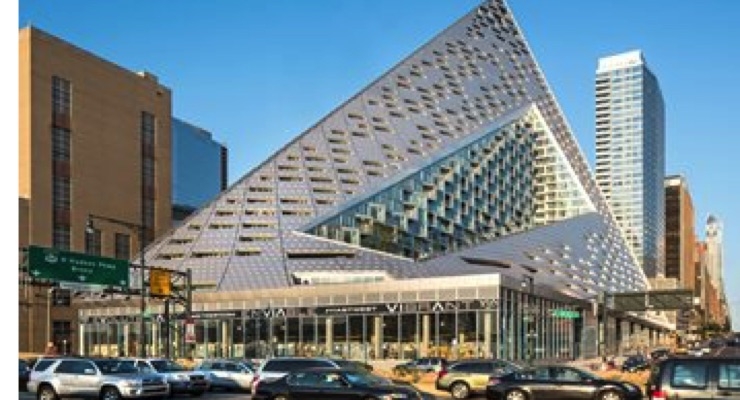

DURANAR coatings by PPG protect and enhance the façade of VIA 57 West, one of New York’s newest and most striking architectural landmarks.

Design by renowned architect Bjarke Ingels, the structure rises 460 feet above the Hudson River to form a swooping metallic pyramid that houses more than 700 upscale river-view apartments.

The sail-shaped façade, which encompasses 515,200 square-feet of metal, glass and concrete, incorporates more than 350,000 square-feet of curtain wall and extruded aluminum window frames partially finished in Duranar Arcadia Silver coatings by PPG. The curtain wall was engineered and fabricated by Tecnoglass, a member of the PPG CAP CERTIFIED APPLICATOR PROGRAM (PPG/CAP) network.

Brian Knapp, PPG director, coil and building products, noted that Duranar coatings have been specified for a number of high-profile projects in New York City recently, including 432 Park Avenue, the world’s tallest residential tower, as well as numerous buildings in Hudson Yards, the largest private real estate development in U.S. history, which is now under construction in Manhattan.

“The durability and colorfastness of Duranar coatings, one of the industry’s first 70-percent fluoropolymer coatings, have been proven for 50 years,” he explained. “From the construction of Javitz Center to the preservation of the Empire State Building, Flatiron Building and Madison Square Garden, generations of New York architects have trusted Duranar coatings to protect the city’s new and cherished landmarks.”

The Duranar Silver Arcadia coating was selected for VIA 57 West to complement a 110,000 square-foot slope wall on the building’s southwest elevation, created from 1,200 stainless steel cladding components. The entire building façade was supplied by Enclos.

Duranar coatings are based on 70-percent polyvinylidene fluoride (PVDF) resin combined with proprietary resin and pigment technologies by PPG. Introduced in 1967, they have added color and beauty to many of the world’s most widely recognized buildings while providing exceptional resistance to chalking, fading, chipping, peeling, dirt collection and chemical staining.

Design by renowned architect Bjarke Ingels, the structure rises 460 feet above the Hudson River to form a swooping metallic pyramid that houses more than 700 upscale river-view apartments.

The sail-shaped façade, which encompasses 515,200 square-feet of metal, glass and concrete, incorporates more than 350,000 square-feet of curtain wall and extruded aluminum window frames partially finished in Duranar Arcadia Silver coatings by PPG. The curtain wall was engineered and fabricated by Tecnoglass, a member of the PPG CAP CERTIFIED APPLICATOR PROGRAM (PPG/CAP) network.

Brian Knapp, PPG director, coil and building products, noted that Duranar coatings have been specified for a number of high-profile projects in New York City recently, including 432 Park Avenue, the world’s tallest residential tower, as well as numerous buildings in Hudson Yards, the largest private real estate development in U.S. history, which is now under construction in Manhattan.

“The durability and colorfastness of Duranar coatings, one of the industry’s first 70-percent fluoropolymer coatings, have been proven for 50 years,” he explained. “From the construction of Javitz Center to the preservation of the Empire State Building, Flatiron Building and Madison Square Garden, generations of New York architects have trusted Duranar coatings to protect the city’s new and cherished landmarks.”

The Duranar Silver Arcadia coating was selected for VIA 57 West to complement a 110,000 square-foot slope wall on the building’s southwest elevation, created from 1,200 stainless steel cladding components. The entire building façade was supplied by Enclos.

Duranar coatings are based on 70-percent polyvinylidene fluoride (PVDF) resin combined with proprietary resin and pigment technologies by PPG. Introduced in 1967, they have added color and beauty to many of the world’s most widely recognized buildings while providing exceptional resistance to chalking, fading, chipping, peeling, dirt collection and chemical staining.