Clariant unveiled solutions fit for elevating industrial coatings to the demanding performance and increasing sustainability requirements of North America’s diverse end-users – the automotive, transportation, building & construction, and consumer & household goods industries.

Delivering innovations in key areas, such as light stability and durability, fire resistance, waterborne and low VOC coatings, and higher solid solvent-borne coatings, the latest additions to Clariant’s portfolio equip local manufacturers to get to the crux of new sector needs and make the most of opportunities in the globally-growing industrial coatings market.

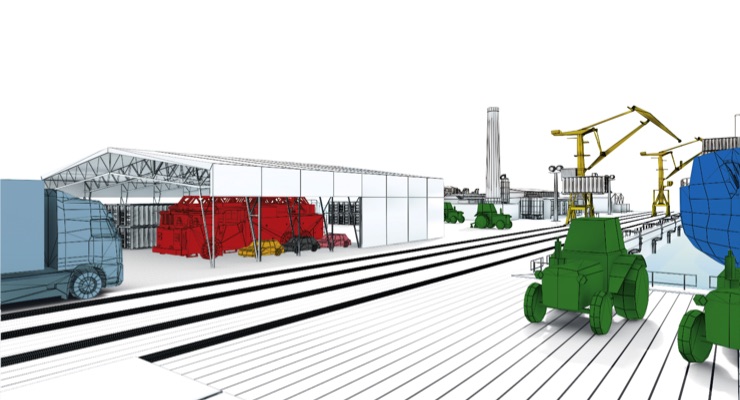

“More is required of industrial coatings, whether for a car or truck, earth-moving equipment or for structural steelwork, than just a finishing decorative touch. Their users look for protection that will extend the lifecycle of industrial applications and deliver high performance in areas such as wear and corrosion resistance," said Tyler Kilgannon, head of sales, BU Additives North America. "At the same time, reduced environmental impact is an increasing priority. Our additives expand the manufacturers’ toolbox so that future coatings can really raise the bar in meeting customer needs."

Clariant now offers manufacturers of intumescent, fire-protective steel coatings the chance to take their products’ sustainability and protection performance a step further.

New halogen-free flame retardant Exolit AP 418 (TP) helps solvent-based intumescent coatings for steel structures to reach up to 10 percent longer fire resistance time compared to conventional solutions.

Clariant’s EcoTain-labelled flame retardant has a favorable environmental and health profile, making no contribution to a solvent-based coating’s VOC emissions.

Clariant also introduced its North American customers to a new solution for water-based intumescent coatings, to sustainably improve the negative impact of cold weather exposure during shipping and storage.

Halogen-free Exolit AP 435 prolongs the shelf life, keeping the coating fluid and workable for longer by preventing paints from either drying out quickly in their pail or becoming unusable due to increased stiffness.

The EcoTain-labelled innovation supports greater use of waterborne coatings and reduces the environmental impact of intumescent coatings.

Clariant is supporting producers of paints and clear coats for metal and plastics automotive components by offering solutions aimed at extending the service life of coatings.

The synergistic high-performance light stabilizer solution AddWorks LXR 313 contributes to increased durability of waterborne and solvent-based clear and pigmented coatings. Formulated without xylene, it extends its benefits from automotive to general industrial applications. AddWorks LXR 313 enables coating formulators to develop new solutions for today’s modern coating systems where light and heat stabilization are key requirements.

The European parliament decided to ban PTFE substances that contain PFOA in a concentration equal to or above 25 parts per billion (grams per thousand tons) with reference to entry 68 of Annex XVII of REACH. The effective date is July 4, 2020, and exemptions that are currently under discussion will only be temporary.

Conforming with this new REACH regulation, Clariant is expanding its portfolio and introducing its new Ceridust 3942 F TP and Ceridust 3943 F TP to give its customers more options to select REACH compliant PTFE wax solutions.

These new micronized PTFE modified polyethylene wax additives enable powder coatings with a fine and homogeneous textured structure and a matte finish.

The new solutions show excellent properties in terms of mar resistance, dirt repellence and anti-slip performance. The need for PFOA REACH-compliant PTFE waxes can also be observed for other coating and also ink applications.

Clariant’s new Ceridust 9203 F TP helps to improve scratch and metal marking resistance as well as the slip performance. Customers benefit from an improved appearance and longevity of coated surfaces and prints.