09.14.23

Research and development company Universal Matter and the National Energy Technology Laboratory (NETL) have created an innovative technology that can transform carbon-rich materials such as coal and coal-wastes into high quality graphene.

Universal Matter received help from NETL’s Carbon Ore Processing Program in a cooperative agreement in order to produce technology called Flash Joule Heating (FJH). The technology transforms carbonous material feedstocks into high quality graphene which could be used in a wide array of materials.

“Universal Matter’s FJH process can convert diverse carbon sources into graphene with tunable characteristics for an almost unlimited number of applications. Universal Matter’s scale-up of FJH graphene production is key because it means the nation’s carbon ore resources can have significant additional application beyond their traditional use in power generation and metallurgy,” said NETL Carbon Ore Processing Program technology manager Joe Stoffa.

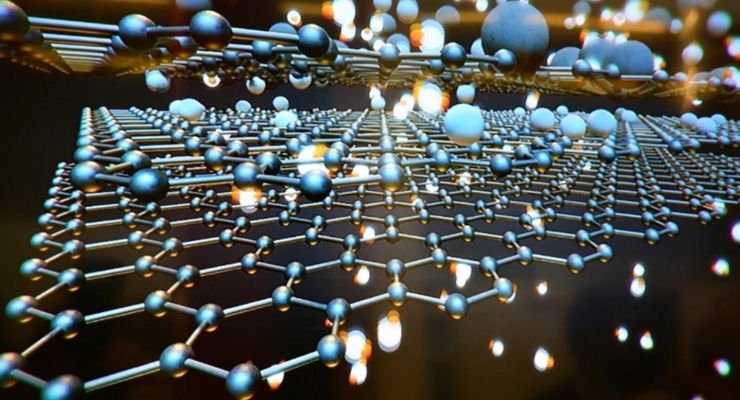

A nanomaterial that is 200 times stronger than steel, graphene consists of a hexagonal lattice of tightly bonded carbon atoms can stretch up to 25% of its original length. Graphene is more electrically conductive than copper, stronger in tensile strength than any know metal, with a high thermal conductivity rate, it has a wide array of uses.

According to the Graphene Council, graphene and other advanced materials are important for next generation aircraft and space vehicles, as well as be useful in the automotive industry.

Graphene also has use in composites, anti-corrosion coatings, concrete and cement, structural materials, asphalt, semiconductors, electronics, sensors, textiles, thermal management, water filtration and more.

Universal Matter received help from NETL’s Carbon Ore Processing Program in a cooperative agreement in order to produce technology called Flash Joule Heating (FJH). The technology transforms carbonous material feedstocks into high quality graphene which could be used in a wide array of materials.

“Universal Matter’s FJH process can convert diverse carbon sources into graphene with tunable characteristics for an almost unlimited number of applications. Universal Matter’s scale-up of FJH graphene production is key because it means the nation’s carbon ore resources can have significant additional application beyond their traditional use in power generation and metallurgy,” said NETL Carbon Ore Processing Program technology manager Joe Stoffa.

A nanomaterial that is 200 times stronger than steel, graphene consists of a hexagonal lattice of tightly bonded carbon atoms can stretch up to 25% of its original length. Graphene is more electrically conductive than copper, stronger in tensile strength than any know metal, with a high thermal conductivity rate, it has a wide array of uses.

According to the Graphene Council, graphene and other advanced materials are important for next generation aircraft and space vehicles, as well as be useful in the automotive industry.

Graphene also has use in composites, anti-corrosion coatings, concrete and cement, structural materials, asphalt, semiconductors, electronics, sensors, textiles, thermal management, water filtration and more.