Kerry Pianoforte, Editor01.23.19

Coatings World: Protecting a substrate from corrosion is one of the most important functions of coatings. What types of products does your company recommend to protect high-value assets (pipelines, outdoor structures, oil rigs, etc.) from corrosion?

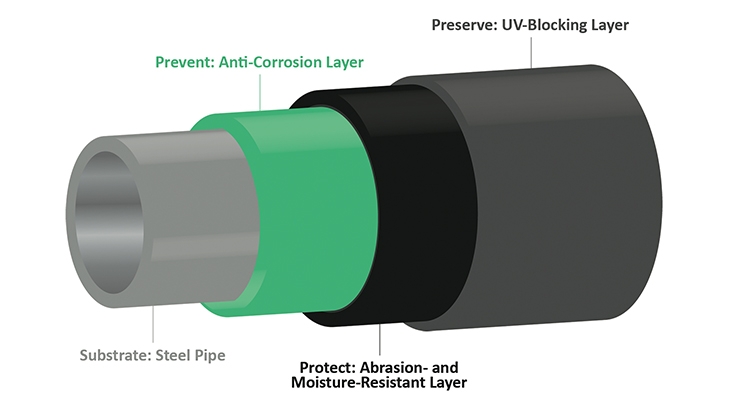

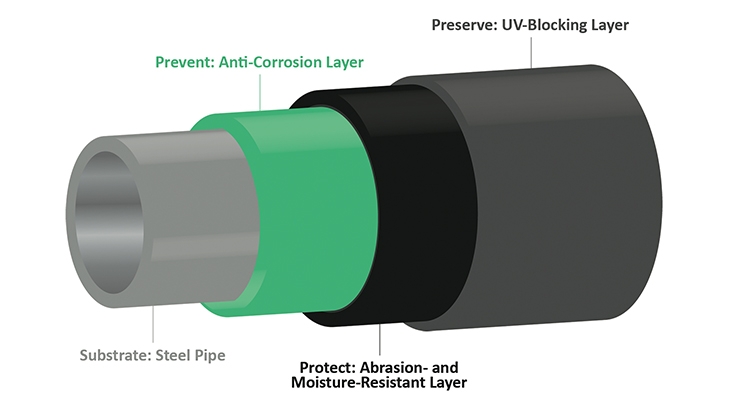

Dr. Jeffrey David Rogozinski, global product director for Sherwin-Williams Protective & Marine Coatings: In the oil and gas pipeline market, a multi-layered coatings approach is advised to prevent pipeline corrosion, protect anti-corrosion coatings and preserve fusion-bonded epoxy (FBE) coatings before pipes are buried in the ground. For example, the ideal base coating layer is an anti-corrosion FBE coating designed to prevent corrosive elements from reaching the steel pipe substrate and working synergistically with cathodic protection systems. Next, a protective, abrasion- and damage resistant FBE coating layer is advised to resist the scratches and scrapes a pipe may encounter from transportation to installation. Such scrapes could otherwise expose the bare steel below and increase corrosion potential. Finally, it’s helpful to consider a preservation layer as an optional topcoat to protect the lower FBE layers against prolonged UV exposure in oftentimes inevitable cases of pipeline installation delays. When building this sort of pipeline protection one layer at a time, remember that all three coating layers will work synergistically and should be selected based on the most stringent performance needs to ensure success.

A multi-layered approach to coating pipelines for long-term performance includes:

• A base anti-corrosion layer to prevent pipeline corrosion;

• An intermediate layer to protect the anti-corrosion layer from wear;

• A UV-blocking layer to preserve the first two layers before burying or submerging pipes

CW: What are the main factors to consider when selecting a corrosion protection coating?

Bruce Toews, global market director – Oil & Gas for Sherwin-Williams Protective & Marine Coatings: On the fuel storage end of the oil and gas chain, tank owners are looking for longer-performing lining materials to help reduce operating costs. Currently, the American Petroleum Institute’s API 653 tank inspection guidelines require 10-year inspection intervals for tank linings, with the expectation that a 20-year life would be acceptable. However, tanks lined 20 years ago with single-coat epoxies are showing no signs of lining failure and are being recertified for another 10-year inspection period. With these coatings offering the potential of at least a 30-year interval between lining applications, it’s possible that inspection intervals will eventually expand to, say, 15 years, which would enable owners to eliminate one complete inspection cycle over 30 years, an efficiency that would add up to significant savings.

CW: How important is substrate preparation as opposed to choosing a higher-end coating?

Toews: Completing surface preparation to an established standard is the foundation for the successful long-term performance of a coating system. However, applicators sometimes encounter substrates that can’t be prepared to the proper standard before applying coating systems. In these situations, the substrate may have a marginally prepared surface that’s far from the recommended surface preparation for the coating’s intended service. Yet, such surfaces can be coated successfully – and deliver long-term performance – when applicators appropriately address two critical factors: the maximum achievable surface preparation and the proper coating system selection.

A marginally prepared surface is likely to have some sort of remaining surface contamination, which could include old coatings, salt, rust, mill scale, oil, grease and more. These contaminants can reduce the effectiveness of the new coating’s mechanical bond with the substrate – and therefore the coating’s service life. In addition, a damp or wet surface could be considered marginal because the moisture may impact the adherence of the new coating system.

With all marginally prepared surfaces, a variety of factors will influence the maximum achievable surface preparation, your coating system selection and the expected service life of the new coating. Those factors include the asset’s operating environment, the adhesion and thickness of previous coatings, the type and extent of any remaining surface contamination, the project’s timing and budget and more.

Numerous high-performance coatings on the market enable application over marginally-prepared surfaces with outstanding results. However, not all coatings will perform well in all scenarios, so it’s important to make a proper selection to ensure long-term performance. Coatings adhere to surfaces in one of three ways – via mechanical bond, chemical bond, or absorption. In the case of a marginally prepared surface, the coating will typically adhere mechanically to the surface it is in contact with. However, it will bond best with any bare steel that’s present on the substrate and not as well on any surfaces with remaining contaminants. In addition, some coatings adhere better to marginal surfaces than others. Therefore, knowing exactly what surface you’re dealing with will allow you to select the right coating system.

CW: What are customers looking for in terms of performance?

Toews: Beyond the need for high-performance coatings that enable rapid returns to service, wider application windows and long-term performance, the majority of our customers have expressed the need for single-source solutions to help enhance efficiencies from ordering to service. Sherwin-Williams Protective & Marine Coatings has positioned itself to be that single source provider for corrosion protection solutions. For example, for midstream companies in the oil and gas industry, we have the capability to provide FBEs from drill pipes to transmission lines, internal flow efficiency coatings, field repair and girth weld coatings, tank linings and more. Similar capabilities are true for a wide array of other markets in which we offer comprehensive product portfolios that enable our customers to truly evaluate the life cycle performance of our materials and make sound decisions for protecting their assets.

Rogozinski: This is true for end users who are looking to reduce their total cost of ownership for assets and increase the time between asset inspections. It’s also true for applicators, who rely on us to ensure ease of application for our robust products while delivering cost advantages related to application efficiency. For applicators, we also offer extensive field support and product training to ensure they know how to best apply our products to ensure success.

CW: What new technologies does your company see being used for corrosion control?

Toews: In the oil and gas industry, the thicker compositions and higher operating temperature requirements of today’s extracted materials are requiring a thoughtful approach to ensuring pipeline integrity with an array of protective coating solutions. This includes high-performance coatings for drill pipe interiors, anti-corrosion and abrasion-resistant coatings that can withstand higher operating temperatures for pipeline exteriors and chemical-resistant lining materials that can effectively protect steel storage tanks from corrosion for decades.

Rogozinski: At the drill site, we need to protect drill pipe interiors from corrosion to enable efficient, safe extractions of corrosive hydrocarbons and other materials at temperatures exceeding 200°C and pressures over 10,000 psi. Those are some of the harshest environments organic coatings are called upon to withstand. Yet, solutions like internal FBE powder coatings are able to protect production tubing, casing and piping from corrosion in these aggressive downhole environments. The coatings provide a smooth inner surface for the drill pipe, which improves hydraulic efficiency for faster drilling and better pumping efficiency.

Toews: For pipelines, external FBE coatings protect against underground soil stress, bacteria and fungus attacks, soil acids and alkalis, as well as underwater threats from salt water. Such FBE coatings are commonly applied in a controlled shop environment to sections of pipe, which are then shipped to the installation site. There, installers must weld the sections of pipe together, leaving a roughly eight-inch section of pipe that is purposefully uncoated to enable girth welding in the field. Properly coating this bare joint in the uncontrolled field environment can be challenging. Installers must be able to complete this protective layer on girth welds efficiently and without error to ensure a fast and reliable installation that will protect the pipeline from corrosion. Solutions such as ultra-high solids, amine-cured epoxy coatings that can be packaged in a variety of ways that ensure proper mixing in the field enable efficient, reliable applications. For example, applicators are able to use a one-liter Burst Pouch® package available on the market that includes both Parts A and B of the Pipeclad® 5000 product unmixed. They can roll the package to burst an interior seam and mix the premeasured contents before opening the package, squeezing out the precisely mixed coating and applying it. This consistency and ease of application helps ensure a properly coated field joint for long-term performance.

CW: What markets offer the most opportunity for growth?

Toews: The oil and gas market is certainly one that’s poised for growth from extraction to transmission to storage. A variety of factors are influencing this market’s need for innovative technologies, with accessibility, efficiency and safety being the key drivers. As the market faces increased demand for natural gas, both raw and processed materials must be transported efficiently and safely from source to source to end user. Therefore, pipeline infrastructure will continue to expand, putting pressures on coating manufacturers, applicators and pipe laying contractors to ensure pipelines are protected over the long haul from corrosion, damage during transit and installation, and premature degradation. Advanced coatings solutions can address all three of these threats to pipeline integrity.

Rogozinski: Expanding domestic and international demand have extended the length of pipelines and increased the requirements for efficiencies in not only how the pipe is laid but also in how easily materials can flow through it. For pipeline installations, manufacturers have added new solutions to enable faster, more accurate pipe welding and corrosion protection operations. Advancements such as easy-to-mix field-applied coatings are allowing installers to better protect girth welds in the field with efficiency and confidence while minimizing risks related to human error. Inside the pipes, new advancements in epoxy coating technology allow natural gas to flow faster and with less turbulence, thereby increasing throughput and decreasing operational expenses.

Finally, safety is an absolute necessity when transporting volatile materials. Any new technologies will need to meet the most stringent performance requirements of governing organizations. And those requirements will continue to become more stringent as the industry pulls more challenging resources from underground.

Dr. Jeffrey David Rogozinski, global product director for Sherwin-Williams Protective & Marine Coatings: In the oil and gas pipeline market, a multi-layered coatings approach is advised to prevent pipeline corrosion, protect anti-corrosion coatings and preserve fusion-bonded epoxy (FBE) coatings before pipes are buried in the ground. For example, the ideal base coating layer is an anti-corrosion FBE coating designed to prevent corrosive elements from reaching the steel pipe substrate and working synergistically with cathodic protection systems. Next, a protective, abrasion- and damage resistant FBE coating layer is advised to resist the scratches and scrapes a pipe may encounter from transportation to installation. Such scrapes could otherwise expose the bare steel below and increase corrosion potential. Finally, it’s helpful to consider a preservation layer as an optional topcoat to protect the lower FBE layers against prolonged UV exposure in oftentimes inevitable cases of pipeline installation delays. When building this sort of pipeline protection one layer at a time, remember that all three coating layers will work synergistically and should be selected based on the most stringent performance needs to ensure success.

• A base anti-corrosion layer to prevent pipeline corrosion;

• An intermediate layer to protect the anti-corrosion layer from wear;

• A UV-blocking layer to preserve the first two layers before burying or submerging pipes

CW: What are the main factors to consider when selecting a corrosion protection coating?

Bruce Toews, global market director – Oil & Gas for Sherwin-Williams Protective & Marine Coatings: On the fuel storage end of the oil and gas chain, tank owners are looking for longer-performing lining materials to help reduce operating costs. Currently, the American Petroleum Institute’s API 653 tank inspection guidelines require 10-year inspection intervals for tank linings, with the expectation that a 20-year life would be acceptable. However, tanks lined 20 years ago with single-coat epoxies are showing no signs of lining failure and are being recertified for another 10-year inspection period. With these coatings offering the potential of at least a 30-year interval between lining applications, it’s possible that inspection intervals will eventually expand to, say, 15 years, which would enable owners to eliminate one complete inspection cycle over 30 years, an efficiency that would add up to significant savings.

CW: How important is substrate preparation as opposed to choosing a higher-end coating?

Toews: Completing surface preparation to an established standard is the foundation for the successful long-term performance of a coating system. However, applicators sometimes encounter substrates that can’t be prepared to the proper standard before applying coating systems. In these situations, the substrate may have a marginally prepared surface that’s far from the recommended surface preparation for the coating’s intended service. Yet, such surfaces can be coated successfully – and deliver long-term performance – when applicators appropriately address two critical factors: the maximum achievable surface preparation and the proper coating system selection.

A marginally prepared surface is likely to have some sort of remaining surface contamination, which could include old coatings, salt, rust, mill scale, oil, grease and more. These contaminants can reduce the effectiveness of the new coating’s mechanical bond with the substrate – and therefore the coating’s service life. In addition, a damp or wet surface could be considered marginal because the moisture may impact the adherence of the new coating system.

With all marginally prepared surfaces, a variety of factors will influence the maximum achievable surface preparation, your coating system selection and the expected service life of the new coating. Those factors include the asset’s operating environment, the adhesion and thickness of previous coatings, the type and extent of any remaining surface contamination, the project’s timing and budget and more.

Numerous high-performance coatings on the market enable application over marginally-prepared surfaces with outstanding results. However, not all coatings will perform well in all scenarios, so it’s important to make a proper selection to ensure long-term performance. Coatings adhere to surfaces in one of three ways – via mechanical bond, chemical bond, or absorption. In the case of a marginally prepared surface, the coating will typically adhere mechanically to the surface it is in contact with. However, it will bond best with any bare steel that’s present on the substrate and not as well on any surfaces with remaining contaminants. In addition, some coatings adhere better to marginal surfaces than others. Therefore, knowing exactly what surface you’re dealing with will allow you to select the right coating system.

CW: What are customers looking for in terms of performance?

Toews: Beyond the need for high-performance coatings that enable rapid returns to service, wider application windows and long-term performance, the majority of our customers have expressed the need for single-source solutions to help enhance efficiencies from ordering to service. Sherwin-Williams Protective & Marine Coatings has positioned itself to be that single source provider for corrosion protection solutions. For example, for midstream companies in the oil and gas industry, we have the capability to provide FBEs from drill pipes to transmission lines, internal flow efficiency coatings, field repair and girth weld coatings, tank linings and more. Similar capabilities are true for a wide array of other markets in which we offer comprehensive product portfolios that enable our customers to truly evaluate the life cycle performance of our materials and make sound decisions for protecting their assets.

Rogozinski: This is true for end users who are looking to reduce their total cost of ownership for assets and increase the time between asset inspections. It’s also true for applicators, who rely on us to ensure ease of application for our robust products while delivering cost advantages related to application efficiency. For applicators, we also offer extensive field support and product training to ensure they know how to best apply our products to ensure success.

CW: What new technologies does your company see being used for corrosion control?

Toews: In the oil and gas industry, the thicker compositions and higher operating temperature requirements of today’s extracted materials are requiring a thoughtful approach to ensuring pipeline integrity with an array of protective coating solutions. This includes high-performance coatings for drill pipe interiors, anti-corrosion and abrasion-resistant coatings that can withstand higher operating temperatures for pipeline exteriors and chemical-resistant lining materials that can effectively protect steel storage tanks from corrosion for decades.

Rogozinski: At the drill site, we need to protect drill pipe interiors from corrosion to enable efficient, safe extractions of corrosive hydrocarbons and other materials at temperatures exceeding 200°C and pressures over 10,000 psi. Those are some of the harshest environments organic coatings are called upon to withstand. Yet, solutions like internal FBE powder coatings are able to protect production tubing, casing and piping from corrosion in these aggressive downhole environments. The coatings provide a smooth inner surface for the drill pipe, which improves hydraulic efficiency for faster drilling and better pumping efficiency.

Toews: For pipelines, external FBE coatings protect against underground soil stress, bacteria and fungus attacks, soil acids and alkalis, as well as underwater threats from salt water. Such FBE coatings are commonly applied in a controlled shop environment to sections of pipe, which are then shipped to the installation site. There, installers must weld the sections of pipe together, leaving a roughly eight-inch section of pipe that is purposefully uncoated to enable girth welding in the field. Properly coating this bare joint in the uncontrolled field environment can be challenging. Installers must be able to complete this protective layer on girth welds efficiently and without error to ensure a fast and reliable installation that will protect the pipeline from corrosion. Solutions such as ultra-high solids, amine-cured epoxy coatings that can be packaged in a variety of ways that ensure proper mixing in the field enable efficient, reliable applications. For example, applicators are able to use a one-liter Burst Pouch® package available on the market that includes both Parts A and B of the Pipeclad® 5000 product unmixed. They can roll the package to burst an interior seam and mix the premeasured contents before opening the package, squeezing out the precisely mixed coating and applying it. This consistency and ease of application helps ensure a properly coated field joint for long-term performance.

CW: What markets offer the most opportunity for growth?

Toews: The oil and gas market is certainly one that’s poised for growth from extraction to transmission to storage. A variety of factors are influencing this market’s need for innovative technologies, with accessibility, efficiency and safety being the key drivers. As the market faces increased demand for natural gas, both raw and processed materials must be transported efficiently and safely from source to source to end user. Therefore, pipeline infrastructure will continue to expand, putting pressures on coating manufacturers, applicators and pipe laying contractors to ensure pipelines are protected over the long haul from corrosion, damage during transit and installation, and premature degradation. Advanced coatings solutions can address all three of these threats to pipeline integrity.

Rogozinski: Expanding domestic and international demand have extended the length of pipelines and increased the requirements for efficiencies in not only how the pipe is laid but also in how easily materials can flow through it. For pipeline installations, manufacturers have added new solutions to enable faster, more accurate pipe welding and corrosion protection operations. Advancements such as easy-to-mix field-applied coatings are allowing installers to better protect girth welds in the field with efficiency and confidence while minimizing risks related to human error. Inside the pipes, new advancements in epoxy coating technology allow natural gas to flow faster and with less turbulence, thereby increasing throughput and decreasing operational expenses.

Finally, safety is an absolute necessity when transporting volatile materials. Any new technologies will need to meet the most stringent performance requirements of governing organizations. And those requirements will continue to become more stringent as the industry pulls more challenging resources from underground.