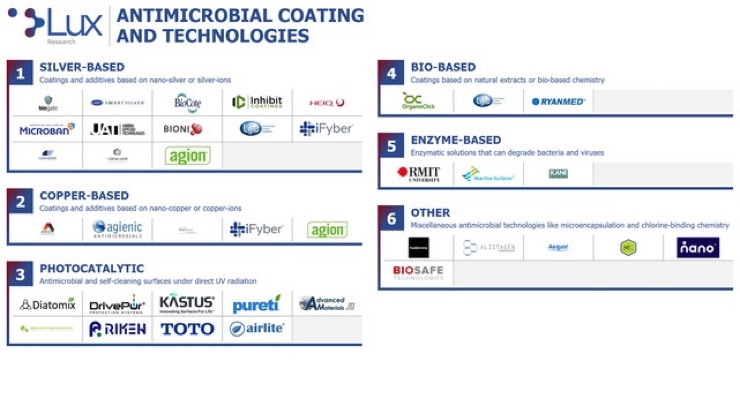

COVID-19 has drastically changed the perception of hygiene and cleanliness, spurring interest in antimicrobial coatings, according to a new report from Lux Research.

These coatings previously struggled to find widespread adoption due to difficulties in quantifying their impact on human health, but the pandemic has drawn attention to them as an important safety measure.

In its new report, “Antimicrobial Coatings at the Front Line of COVID-19,” Lux Research outlines key challenges and opportunities for coatings, additives, and materials innovation and how they will impact several major industries.

“COVID-19 has driven substantial interest in antimicrobial coatings this year and is proving to be a catalyst for antimicrobial research and funding,” said Tiffany Hua, research associate at Lux Research. “We expect this interest to spike even further before the end of 2020 and be a trend of continued interest in the materials and coatings industry.”

Major manufacturers like Ford Motor Company are talking about incorporating these types of coatings into their products, while startups like HeiQ bring out new antimicrobial coatings for applications like textiles.

However, not all antimicrobial coatings are created equal – some are only effective against bacteria and not necessarily viruses, so users need to choose carefully.

“When considering the wide range of solutions used as preventive measures against COVID-19, it is important to understand the limitations of these technologies,” said Hua.“Metallic antimicrobial agents like silver and copper can be effective against both bacteria and viruses, but ensuring their effectiveness when dispersed in coating matrices still poses challenges.”

Other solutions like photocatalytic, enzyme-based, and bio-based coatings have also been shown to be effective against bacteria and viruses.

Light-activated, photocatalytic coatings are on the rise, thanks to their self-cleaning functionality and effectiveness against viruses.

These coatings use materials like nano-titanium dioxide (TiO2) that absorb UV light and produce reactive radicals that break down organic compounds and pollutants on surfaces.

“Photocatalytic coating developers have historically targeted the elimination of pollution and smog, but COVID-19 has driven more use in antimicrobial applications, as they can be effective against both bacteria and viruses,” Hua said.

Bio-based antimicrobial technologies are also gaining attention, utilizing natural extracts and bio-based solutions to impart antimicrobial properties.

Food packaging currently consumes the majority of bio-based antimicrobial technologies, but they could expand to other sectors as innovation continues to increase.

Antimicrobial enzymes are another option, as some can also produce reactive oxygen species that kill bacteria under light and can produce longer-lasting antimicrobial coatings.

Antimicrobial coatings are still far from perfect, as efficacy and durability are still major challenges.

“These technologies lack certainty and documentation around performance while still struggling to prove that their incorporation leads to better health outcomes,” said Hua. “Regulatory approval is another challenge, as new disinfectant and antimicrobial solutions must have EPA and FDA approval to make effectiveness claims. There are also health and environmental concerns that need to be addressed and have increased regulation and oversight. With a surge in research and funding, there will be less concern over performance and regulation.”

Lux Research expects major growth of antimicrobial coatings within the transportation and medical industries, as well as deployment in public spaces. Over the next two years, more opportunities will emerge within apparel, food, and packaging applications, while in the longer term, automotive OEMs and other consumer product companies will adopt them.