John A. Gilbert, Behr Process Corporation09.13.16

The architectural coatings industry has undergone great change over the last ten years. Today’s coatings have a much different raw material base, a different environmental profile and different properties. These changes have been brought about through a variety of influencers including synthesis chemists, paint formulators, end users, and environmental regulators. This paper examines some of the changes that have happened in the last decade as well as some trends coming in the near future.

Waterborne vs. Oil-Based/Solvent-Based

One cannot comment on changes in architectural coatings without first addressing the transition from oil/solvent-based paint to waterborne paint.

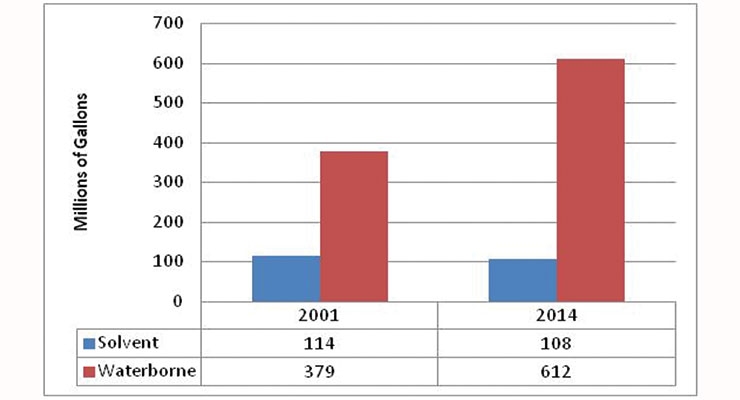

As I began work on this paper, the 9th Edition of the ACA’s Industry Market Analysis was published by the ACA and Chemquest.1 In their analysis of the overall U.S. architectural coatings market, they reported that in 2014 solvent-based coatings made up 108 million gallons, or 15 percent, of a 720 million gallon market (Figure 1).

By contrast, in 2001, solvent-based coatings made up 114 million gallons, or 23 percent of a 493 million gallon market. Therefore, one can conclude that although the total volume of solvent-based paint has only slightly decreased, it is now a smaller percentage of a larger market. In fact, as discussed below, there are certain U.S. markets in which it is very difficult to use some types of solvent-based paints due to environmental regulation. Although the reduction in market share of solvent-based coatings has continued for several decades, there are certain regional markets and specialized applications which favor the use of solvent-based materials. For the average end user, waterborne paints offer the convenience of a safe, low-odor product and easy cleanup with soap and water.

VOC Content

The first latex-based, waterborne coatings were much higher in VOC (volatile organic compound) content than those on the market today. Even as recently as 2006, it was common to formulate waterborne architectural coatings at 250 g/L VOC. Many of the resins for such coatings required the use of solvents in order to coalesce the latex particles into a continuous film. As regulations have driven VOC values downward, resins have been designed which require little or no solvent in order to form a film. In addition, zero-VOC coalescents have been developed. Resin and paint developers have been tasked with finding ways to maintain a low minimum film formation temperature (MFFT) while at the same time maintaining the hardness of the dried film.

This is challenging because the low MFFT resins tend to have lower glass transition temperatures and the zero-VOC coalescents stay in the dried film. In fact, I see this as one of the biggest technical challenges in waterborne architectural coatings today: how to make paint at zero VOC that will coalesce appropriately at room temperature and yet dry to a hard, durable finish. This problem becomes particularly challenging at higher gloss levels because the formulations consist of more resin and less pigment.

Another challenge brought about by the lack of VOC in waterborne paint is open time or workability. Without the presence of slow-evaporating solvents, the paint will quickly become tacky when the water evaporates. In low humidity environments, water is quickly released from the paint as it is applied. Therefore, a second technical challenge for material developers is to come up with raw materials that enable longer open time for the paint user. It is not clear if this will be most easily achieved through binder design or through additive design.

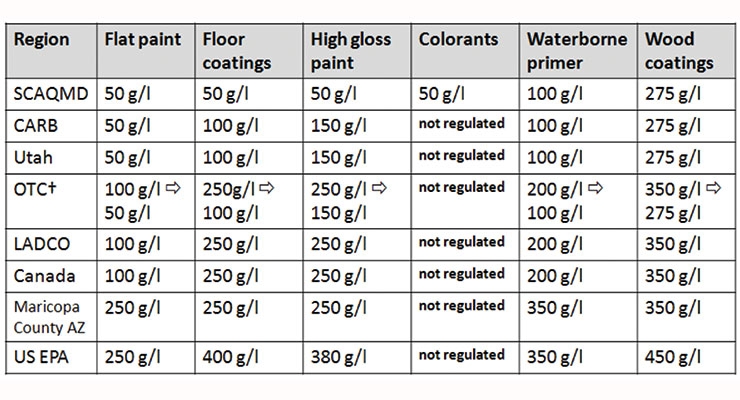

The data in Table 1 show the current state of architectural paint VOC regulation in North America.2-7 Clearly, there are areas in which higher VOC coatings are still allowed. However, markets like California, the Ozone Transport Commission (OTC) states and the Lake Michigan Air Directors Consortium (LADCO) states drive manufacturers toward lower VOC formulations. The OTC includes twelve states plus the District of Columbia in the region from Virginia to Maine. The LADCO states include Illinois, Indiana, Michigan, Wisconsin, Ohio and Minnesota. To produce special formulations for each market is quite a logistical and formulation management challenge. For this reason, many coatings companies simply supply coatings nationwide that are compliant with the most stringent regulatory market, currently the South Coast Air Quality Management District of California (SCAQMD). In addition to being the district with the most stringent VOC regulations, SCAQMD is the only district with limitations on colorant VOC. This district is currently in the process of updating its VOC rules for architectural coatings. In particular, the so-called “small container exemption,” which allows manufacturers to sell higher VOC products in quantities of one liter or less, will be restricted. Note that the OTC has recently adopted the latest California Air Resources Board (CARB) standards.

The regulatory landscape can be challenging to understand. California, for example, is made up of 35 different air districts but only a portion have adopted the current (or even the previous) CARB standards. Similarly, not every OTC or LADCO state has adopted its region’s standards. However, what is very clear is that the regulations will continue to become more rather than less stringent. The Clean Air Act requires the EPA to review the National Ozone Standard every five years to protect public health. In 2008, the EPA lowered the standard to 0.075 parts per million (ppm). Very recently, on October 1, 2015, the EPA lowered the standard to 0.070 ppm. As a result, more states and counties in the United States will be driven to create more stringent local VOC standards in order to attain the new ozone limits. It is unclear today if and when the EPA will begin the work of updating the national VOC standard which today allows far higher VOC levels than those districts that have implemented more recent rulings.

Alkylphenol Ethoxylates (APEOs)

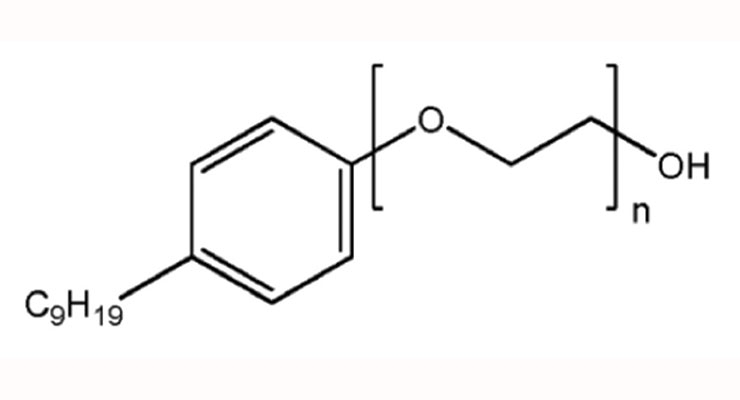

Alkylphenol ethoxylates have been in use for many years because of their surfactant properties. For the last decade, they have been severely restricted from use in the European market due to concerns around their aquatic toxicity profile and bioaccumulation profile.10 Further concern exists that their biodegradation pathway may result in the formation of the corresponding alkylphenols, which have bioaccumulation profiles of greater concern than the ethoxylated analogs.11 The most commonly used APEOs are based on nonylphenol (Figure 2).

As with many chemical compounds, there is disagreement in the industry concerning the level of risk associated with their usage. In the North American market, formulators have been encouraged to voluntarily eliminate APEOs, although there is no regulation. The author’s company has gradually and voluntarily replaced older generation APEO-containing materials with APEO-free resins and surfactants, even though customers and regulatory agencies are not insisting on it. Indeed, one of the benefits of waterborne coatings is that the application tools can be easily cleaned up with soap and water, therefore it is desirable not to have water soluble chemicals of environmental concern in the formulation. If there is a chance that a material in the paint is toxic to aquatic life, we would rather err on the side of caution and eliminate it.

In-Can Preservation

As VOC levels in architectural coatings have been reduced, preservation of finished paints and also paint ingredients against biological contamination has become more challenging. A waterborne paint formulated at 250 g/L has enough alcohol solvent in it to prevent growth of microorganisms in the can. Today, however, most paints are formulated at 50 g/L or below, increasing their ability to support the proliferation of microorganisms. Unfortunately, the options available to paint formulators are limited.

Formaldehyde-containing preservatives came under scrutiny many years ago and have been mostly formulated out of waterborne paints. Isothiazolinone derivatives have been used effectively as substitutes, but there are concerns around skin sensitization with such products. In Europe, new labeling requirements for isothiazolinone derivatives became active in June of this year.12 These requirements require that an “allergen phrase” appear on labels of paints containing > 1.5 ppm of CMIT/MIT (5-chloro-2-methyl-isothiazolin-3-one / 2-methyl-isothiazolin-3-one), > 50 ppm BIT (1,2-benzisothiazolin-3-one), and > 60 ppm MIT (2-methyl-isothiazolin-3-one). These levels are, for the most part, below the concentration at which these materials are useful as preservatives, forcing most companies to put the statement “Contains [active ingredient]. May produce an allergic reaction.” on the label. It is not clear if any legislation of this type will regulate isothiazolinone derivatives in the United States in the future.

Various forms of zinc, silver or copper preservatives have been made available to paint formulators as well, although they can cause associated challenges with paint stability and film discoloration. Pyrithione compounds can be used alone or in combination with other preservatives and are generally recognized as safe. In summary, today’s architectural coatings are more susceptible to biological contamination because of their low VOC content. However, the preservation options are limited due to the regulatory and safety limitations of these materials.

Some combinations of preservatives, when used at higher levels, can actually allow the coating to provide a sanitizing effect. In other words, bacteria, mold or viruses from the environment which come into contact with such a coating will be killed off by the preservative at the film’s surface. In the United States, the EPA strictly regulates the claims that can be made relative to human health. Although they allow phrases on the label that fall under the “treated article exemption,” any further claims require significant testing and approval under EPA protocol.13 Therefore, it is common to see label claims related to the dried film being resistant to microorganisms, but it is not common to see claims related to keeping people healthy.

Labor Savings

Since 2009 there has been a major transition in the North American market to paint-and-primer-in-one products. These products are designed to provide primer properties in the topcoat itself, allowing the user to complete a job in a shorter amount of time. If a topcoat can provide adhesion to the substrate, hide imperfections, block minor stains, and give a uniform appearance, then the user can eliminate the step of applying a primer layer. In most cases, a consumer who is performing a residential repaint can apply a paint-and-primer-in-one product. Common sense should prevail in challenging jobs: it is still recommended that a traditional primer be used if the substrate is difficult to adhere to, if the job involves varying porosity in the substrate, if heavy stains are present, if there is bare weathered wood, or if the paint needs to cover severe water or smoke damage. For a typical homeowner attempting to repaint a room over a weekend, paint-and-primer-in-one products offer the opportunity to finish the job faster, along with the convenience of only having to buy topcoat (rather than primer and topcoat).

Another labor-saving trend in the North American market has been a transition to better hiding in architectural coatings. Several items have contributed to enable hiding using fewer coats. First, the development of higher dispensing accuracy of point-of-sale tinting equipment has allowed for the use of more concentrated colorants for tinting. The result is that more color pigment can be incorporated in paint by a given volume of colorant, resulting in better hiding. In addition, the development of paint materials that help to properly space titanium dioxide in the dried film has contributed to improved hiding. Third, the introduction of higher hiding color pigments such as pigment red 254 or pigment yellow 184 allows the formulation of colors with high contrast ratios. As a result, today it is more likely that a paint job can be done in one or, at most, two coats.

Deck Restoration Coatings

One of the trends in the last few years has been the appearance of deck restoration coatings. These are opaque, solid color materials designed for application to a wood deck at a thick film, typically eight to twelve mils. As wood decks age, they can develop cracks and splinters as well as a visually unsatisfying appearance. Replacing a wood deck can be very expensive; therefore lengthening the service life by a few years with a restoration coating can be desirable. By utilizing a deck restoration coating, the customer can make an older deck functional while at the same time delaying the cost of replacing it. Figure 3 shows a sample of a deck restoration coating applied to a weathered board with cracks.

To be effective, the coating must have the ability to bridge cracks, cover up splinters and hide visual defects. As is the case with any coating on a horizontal surface, the substrate must be properly prepared before application is attempted.

Exterior Paint Properties

Keeping the exterior of a house looking fresh and new can be challenging. Many homes experience extremes of temperature, precipitation, sunlight and particulate matter from the environment. One area of emphasis in the last ten years has been dirt pickup resistance. This is the ability of the coating to retain its original color even after exposure to dust and smog particles. The best way to evaluate dirt pickup resistance is two expose painted panels to an outdoor environment. However, waiting for differentiation of coatings by natural exposure can take a year or longer. Accelerated methods involving wet or dry exposure to dirt have been employed in laboratories in order to predict dirt pickup resistance. This is a difficult property to quantify because there is great variation in the type of dust or dirt present in any given environment, as well as variation in temperature and rainfall.

In general, coatings that are higher in gloss, smoother and harder at the surface have better dirt pickup resistance. The more porous, rough surface of a flat coating allows for dirt to get stuck in the valleys between the pigment particles. A lower Tg coating can allow for dirt to embed itself in the surface when the weather is warm and the coating is soft. Even so, within a given sheen/hardness of coating, one can see great variation in resistance to dirt pickup. There is no magic formula for a coating with good dirt pickup; we have arrived at most of our formulas by testing individual ingredients in each class of material (binder, thickener, additive, etc.). In Figure 4, you can see a demonstration of the variation in dirt pickup resistance of four exterior satin formulations.

In this test, dry dirt was applied to the bottom half of the coated panel. After 10 minutes, the panel was turned vertical so that most of the dirt fell from the surface of the film. As you can see, one coating retains significantly less dirt than the others.

Exterior elastomeric coatings represent a particular challenge for achieving dirt pickup resistance. These coatings are designed to be highly flexible so that they can bridge cracks in the substrate as they form. However, this results in a rather soft, low Tg film that can allow dirt to stick at the surface and embed itself in the coating. Future material development efforts will be aimed at making flexible coatings with some hardness at the coating/air interface to prevent dirt from sticking. Currently, ASTM subcommittee D01.42 is working on publishing a new test method for measuring dirt pickup resistance of architectural coatings.

Another important property for exterior paint is the development of integrity against rain early in the life of the coating, or “early rain resistance.” Exterior painters cannot predict exactly when rainfall will occur. It is desirable to have a coating that will not be damaged or washed away by a rain shower one or two hours after it is applied. This property can be easily tested by exposing painted panels to water streaming from a shower head at a controlled flow rate (Figure 5).

Early rain resistance is achieved by creating a coating that coalesces quickly and accelerates water leaving the film. Usually this property comes at the expense of dry time: a coating that has early rain resistance will become dry to touch very quickly.

VOC-Compliant Oil-Based Materials

Despite the recent trend to waterborne coatings, there are some applications in which oil-based materials are still preferred. For those who want the look and feel of an oil-based wood stain for their deck or gazebo, these materials offer the advantages of good penetration into the wood as well as a water-repelling effect. In general, they need to be re-applied every year or two.

However, these materials are generally very high in VOC and only allowed, in their traditional form, in 33 states. Today product developers are working with low volatility oils and oil derivatives that can provide acceptable application viscosity with less reducing solvent. In some cases, exempt solvents can be used to allow viscosity reduction without adding to the VOC value.

Reduction of VOC of the finished product to 275 g/L allows it to be sold in most areas of the United States, although the South Coast Air Quality Management District of California requires 100 g/L. Similar to the paint analogs, the lowering of VOC in these products presents some challenges as return-to-service time (due to long dry time) and dirt pickup resistance (Figure 6) can be compromised.

New Looks

It is possible to produce many novel, eye-catching looks by using special paint application techniques. Faux finish and glaze techniques have been around for many years. Distressed looks which give the appearance of a rusted surface or a tarnished metal are popular. It is possible, with some practice, to become proficient at applying such looks to a wall. In addition, there are many contractors in the market offering professional application of these looks. However, for the average do-it-yourself painter, achieving these looks may require too much skill or artistic talent, and many homeowners are not willing to take on such a project.

Therefore, one of the challenges for today’s paint manufacturers is to develop products that can provide new looks (as opposed to a single, homogeneous color) with a very simple and easy application process. One very appealing product which has gained some traction in China is “multicolor paint,” which mimics the look of natural stone such as granite or marble. Such coatings are made by producing a product that has individual domains of color which do not mix with each other. When sprayed over a base color, the final finish has an appearance of natural stone. Today this look can only be achieved by spraying, but a version that could be applied with a paint roller would be more suitable to the average do-it-yourselfer who may not be willing to use spray equipment. Figure 7 shows a prototype of a roller-applied multicolor paint.

Another way of achieving a new look is to incorporate some type of larger colored particles into a paint formulation. There are a variety of available raw materials that can be used for this purpose. In general, they need to be larger in diameter than the film thickness of the dried paint so that they are visible after the job is finished. By using various types and sizes of colored particles, a variety of effects can be achieved. Again, this type of coating can be applied by spray or roll application, although most homeowners will prefer to use a roller. The texture arising from the larger particles is useful for providing an aesthetically appealing, non-slip surface to concrete walkways and patios. Figure 8 shows a close up view of such a coating, illustrating the texture achieved via the use of large particle flakes.

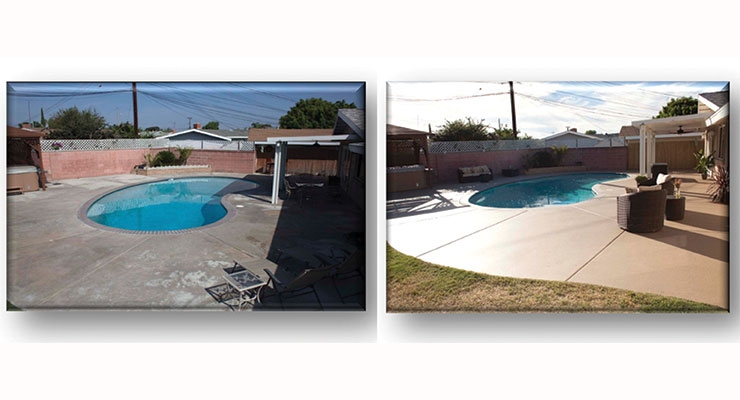

In Figure 9, one can observe the appearance improvement resulting from the application of this type of coating to the aged concrete on a pool deck.

Summary

The architectural coatings industry has enjoyed a period of healthy innovation over the last decade. A few of the key drivers have been the conversion from oil-based to waterborne paint, VOC reduction, removal of chemicals of concern, the emergence of paint-and-primer-in one products, the desire to provide improved film properties such as dirt pickup resistance and early rain resistance, and the desire to provide easy-to-apply new looks. Coatings formulation continues to be a field rich in innovation. As consumer tastes change, regulatory rules change and new raw materials become available, paint formulators will continue to use their expertise and creativity to produce new products.

References

1. ACA Industry Market Analysis 9th Edition, Chemquest; American Coatings Association, 2015; Ch. 7, p 11.

2. California Air Resources Board web site. http://www.arb.ca.gov/coatings/arch/voclimits.htm

3. South Coast Air Quality Management District web site http://www.aqmd.gov/home/regulations/compliance/architectural-coatings

4. Ozone Transport Commission web site. http://www.otcair.org/

5. Lake Michigan Air Directors Consortium web site. http://www.ladco.org/about/

6. Utah Department of Environmental Quality web site. http://www.deq.utah.gov/FactSheets/fspages/consumerproducts.htm

7. Maricopa County web site. https://www.maricopa.gov/aq/divisions/planning_analysis/AdoptedRules.aspx

8. Environment Canada web site. http://www.ec.gc.ca/lcpe-cepa/eng/regulations/detailReg.cfm?intReg=117

9. SCAQMD web site. http://www.aqmd.gov/docs/default-source/planning/architectural-coatings/current-activities-support-documents/2015_9_par1113_pcm.pdf?sfvrsn=6

10. TFL web site. http://www.tfl.com/web/files/Statement_NPE-surfactants.pdf

11. Wikipedia web site. https://en.wikipedia.org/wiki/Nonylphenol

12. Brown, S. Achieving Successful Microbial Protection While Staying Below EUH208 Limits. Proceedings of the European Coatings Conference, Nuremberg, Germany, April 20-21, 2015.

13. United States Environmental Protection Agency web site. http://www2.epa.gov/sites/production/files/2014-04/documents/pr2000-1.pdf

Waterborne vs. Oil-Based/Solvent-Based

One cannot comment on changes in architectural coatings without first addressing the transition from oil/solvent-based paint to waterborne paint.

As I began work on this paper, the 9th Edition of the ACA’s Industry Market Analysis was published by the ACA and Chemquest.1 In their analysis of the overall U.S. architectural coatings market, they reported that in 2014 solvent-based coatings made up 108 million gallons, or 15 percent, of a 720 million gallon market (Figure 1).

By contrast, in 2001, solvent-based coatings made up 114 million gallons, or 23 percent of a 493 million gallon market. Therefore, one can conclude that although the total volume of solvent-based paint has only slightly decreased, it is now a smaller percentage of a larger market. In fact, as discussed below, there are certain U.S. markets in which it is very difficult to use some types of solvent-based paints due to environmental regulation. Although the reduction in market share of solvent-based coatings has continued for several decades, there are certain regional markets and specialized applications which favor the use of solvent-based materials. For the average end user, waterborne paints offer the convenience of a safe, low-odor product and easy cleanup with soap and water.

VOC Content

The first latex-based, waterborne coatings were much higher in VOC (volatile organic compound) content than those on the market today. Even as recently as 2006, it was common to formulate waterborne architectural coatings at 250 g/L VOC. Many of the resins for such coatings required the use of solvents in order to coalesce the latex particles into a continuous film. As regulations have driven VOC values downward, resins have been designed which require little or no solvent in order to form a film. In addition, zero-VOC coalescents have been developed. Resin and paint developers have been tasked with finding ways to maintain a low minimum film formation temperature (MFFT) while at the same time maintaining the hardness of the dried film.

This is challenging because the low MFFT resins tend to have lower glass transition temperatures and the zero-VOC coalescents stay in the dried film. In fact, I see this as one of the biggest technical challenges in waterborne architectural coatings today: how to make paint at zero VOC that will coalesce appropriately at room temperature and yet dry to a hard, durable finish. This problem becomes particularly challenging at higher gloss levels because the formulations consist of more resin and less pigment.

Another challenge brought about by the lack of VOC in waterborne paint is open time or workability. Without the presence of slow-evaporating solvents, the paint will quickly become tacky when the water evaporates. In low humidity environments, water is quickly released from the paint as it is applied. Therefore, a second technical challenge for material developers is to come up with raw materials that enable longer open time for the paint user. It is not clear if this will be most easily achieved through binder design or through additive design.

The data in Table 1 show the current state of architectural paint VOC regulation in North America.2-7 Clearly, there are areas in which higher VOC coatings are still allowed. However, markets like California, the Ozone Transport Commission (OTC) states and the Lake Michigan Air Directors Consortium (LADCO) states drive manufacturers toward lower VOC formulations. The OTC includes twelve states plus the District of Columbia in the region from Virginia to Maine. The LADCO states include Illinois, Indiana, Michigan, Wisconsin, Ohio and Minnesota. To produce special formulations for each market is quite a logistical and formulation management challenge. For this reason, many coatings companies simply supply coatings nationwide that are compliant with the most stringent regulatory market, currently the South Coast Air Quality Management District of California (SCAQMD). In addition to being the district with the most stringent VOC regulations, SCAQMD is the only district with limitations on colorant VOC. This district is currently in the process of updating its VOC rules for architectural coatings. In particular, the so-called “small container exemption,” which allows manufacturers to sell higher VOC products in quantities of one liter or less, will be restricted. Note that the OTC has recently adopted the latest California Air Resources Board (CARB) standards.

The regulatory landscape can be challenging to understand. California, for example, is made up of 35 different air districts but only a portion have adopted the current (or even the previous) CARB standards. Similarly, not every OTC or LADCO state has adopted its region’s standards. However, what is very clear is that the regulations will continue to become more rather than less stringent. The Clean Air Act requires the EPA to review the National Ozone Standard every five years to protect public health. In 2008, the EPA lowered the standard to 0.075 parts per million (ppm). Very recently, on October 1, 2015, the EPA lowered the standard to 0.070 ppm. As a result, more states and counties in the United States will be driven to create more stringent local VOC standards in order to attain the new ozone limits. It is unclear today if and when the EPA will begin the work of updating the national VOC standard which today allows far higher VOC levels than those districts that have implemented more recent rulings.

Alkylphenol Ethoxylates (APEOs)

Alkylphenol ethoxylates have been in use for many years because of their surfactant properties. For the last decade, they have been severely restricted from use in the European market due to concerns around their aquatic toxicity profile and bioaccumulation profile.10 Further concern exists that their biodegradation pathway may result in the formation of the corresponding alkylphenols, which have bioaccumulation profiles of greater concern than the ethoxylated analogs.11 The most commonly used APEOs are based on nonylphenol (Figure 2).

As with many chemical compounds, there is disagreement in the industry concerning the level of risk associated with their usage. In the North American market, formulators have been encouraged to voluntarily eliminate APEOs, although there is no regulation. The author’s company has gradually and voluntarily replaced older generation APEO-containing materials with APEO-free resins and surfactants, even though customers and regulatory agencies are not insisting on it. Indeed, one of the benefits of waterborne coatings is that the application tools can be easily cleaned up with soap and water, therefore it is desirable not to have water soluble chemicals of environmental concern in the formulation. If there is a chance that a material in the paint is toxic to aquatic life, we would rather err on the side of caution and eliminate it.

In-Can Preservation

As VOC levels in architectural coatings have been reduced, preservation of finished paints and also paint ingredients against biological contamination has become more challenging. A waterborne paint formulated at 250 g/L has enough alcohol solvent in it to prevent growth of microorganisms in the can. Today, however, most paints are formulated at 50 g/L or below, increasing their ability to support the proliferation of microorganisms. Unfortunately, the options available to paint formulators are limited.

Formaldehyde-containing preservatives came under scrutiny many years ago and have been mostly formulated out of waterborne paints. Isothiazolinone derivatives have been used effectively as substitutes, but there are concerns around skin sensitization with such products. In Europe, new labeling requirements for isothiazolinone derivatives became active in June of this year.12 These requirements require that an “allergen phrase” appear on labels of paints containing > 1.5 ppm of CMIT/MIT (5-chloro-2-methyl-isothiazolin-3-one / 2-methyl-isothiazolin-3-one), > 50 ppm BIT (1,2-benzisothiazolin-3-one), and > 60 ppm MIT (2-methyl-isothiazolin-3-one). These levels are, for the most part, below the concentration at which these materials are useful as preservatives, forcing most companies to put the statement “Contains [active ingredient]. May produce an allergic reaction.” on the label. It is not clear if any legislation of this type will regulate isothiazolinone derivatives in the United States in the future.

Various forms of zinc, silver or copper preservatives have been made available to paint formulators as well, although they can cause associated challenges with paint stability and film discoloration. Pyrithione compounds can be used alone or in combination with other preservatives and are generally recognized as safe. In summary, today’s architectural coatings are more susceptible to biological contamination because of their low VOC content. However, the preservation options are limited due to the regulatory and safety limitations of these materials.

Some combinations of preservatives, when used at higher levels, can actually allow the coating to provide a sanitizing effect. In other words, bacteria, mold or viruses from the environment which come into contact with such a coating will be killed off by the preservative at the film’s surface. In the United States, the EPA strictly regulates the claims that can be made relative to human health. Although they allow phrases on the label that fall under the “treated article exemption,” any further claims require significant testing and approval under EPA protocol.13 Therefore, it is common to see label claims related to the dried film being resistant to microorganisms, but it is not common to see claims related to keeping people healthy.

Labor Savings

Since 2009 there has been a major transition in the North American market to paint-and-primer-in-one products. These products are designed to provide primer properties in the topcoat itself, allowing the user to complete a job in a shorter amount of time. If a topcoat can provide adhesion to the substrate, hide imperfections, block minor stains, and give a uniform appearance, then the user can eliminate the step of applying a primer layer. In most cases, a consumer who is performing a residential repaint can apply a paint-and-primer-in-one product. Common sense should prevail in challenging jobs: it is still recommended that a traditional primer be used if the substrate is difficult to adhere to, if the job involves varying porosity in the substrate, if heavy stains are present, if there is bare weathered wood, or if the paint needs to cover severe water or smoke damage. For a typical homeowner attempting to repaint a room over a weekend, paint-and-primer-in-one products offer the opportunity to finish the job faster, along with the convenience of only having to buy topcoat (rather than primer and topcoat).

Another labor-saving trend in the North American market has been a transition to better hiding in architectural coatings. Several items have contributed to enable hiding using fewer coats. First, the development of higher dispensing accuracy of point-of-sale tinting equipment has allowed for the use of more concentrated colorants for tinting. The result is that more color pigment can be incorporated in paint by a given volume of colorant, resulting in better hiding. In addition, the development of paint materials that help to properly space titanium dioxide in the dried film has contributed to improved hiding. Third, the introduction of higher hiding color pigments such as pigment red 254 or pigment yellow 184 allows the formulation of colors with high contrast ratios. As a result, today it is more likely that a paint job can be done in one or, at most, two coats.

Deck Restoration Coatings

One of the trends in the last few years has been the appearance of deck restoration coatings. These are opaque, solid color materials designed for application to a wood deck at a thick film, typically eight to twelve mils. As wood decks age, they can develop cracks and splinters as well as a visually unsatisfying appearance. Replacing a wood deck can be very expensive; therefore lengthening the service life by a few years with a restoration coating can be desirable. By utilizing a deck restoration coating, the customer can make an older deck functional while at the same time delaying the cost of replacing it. Figure 3 shows a sample of a deck restoration coating applied to a weathered board with cracks.

To be effective, the coating must have the ability to bridge cracks, cover up splinters and hide visual defects. As is the case with any coating on a horizontal surface, the substrate must be properly prepared before application is attempted.

Exterior Paint Properties

Keeping the exterior of a house looking fresh and new can be challenging. Many homes experience extremes of temperature, precipitation, sunlight and particulate matter from the environment. One area of emphasis in the last ten years has been dirt pickup resistance. This is the ability of the coating to retain its original color even after exposure to dust and smog particles. The best way to evaluate dirt pickup resistance is two expose painted panels to an outdoor environment. However, waiting for differentiation of coatings by natural exposure can take a year or longer. Accelerated methods involving wet or dry exposure to dirt have been employed in laboratories in order to predict dirt pickup resistance. This is a difficult property to quantify because there is great variation in the type of dust or dirt present in any given environment, as well as variation in temperature and rainfall.

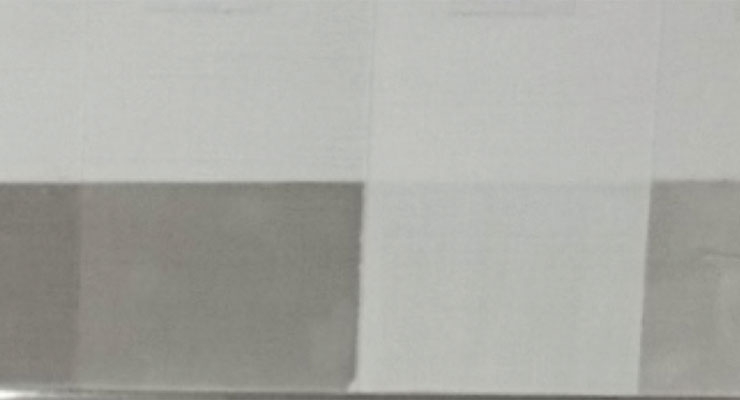

In general, coatings that are higher in gloss, smoother and harder at the surface have better dirt pickup resistance. The more porous, rough surface of a flat coating allows for dirt to get stuck in the valleys between the pigment particles. A lower Tg coating can allow for dirt to embed itself in the surface when the weather is warm and the coating is soft. Even so, within a given sheen/hardness of coating, one can see great variation in resistance to dirt pickup. There is no magic formula for a coating with good dirt pickup; we have arrived at most of our formulas by testing individual ingredients in each class of material (binder, thickener, additive, etc.). In Figure 4, you can see a demonstration of the variation in dirt pickup resistance of four exterior satin formulations.

In this test, dry dirt was applied to the bottom half of the coated panel. After 10 minutes, the panel was turned vertical so that most of the dirt fell from the surface of the film. As you can see, one coating retains significantly less dirt than the others.

Exterior elastomeric coatings represent a particular challenge for achieving dirt pickup resistance. These coatings are designed to be highly flexible so that they can bridge cracks in the substrate as they form. However, this results in a rather soft, low Tg film that can allow dirt to stick at the surface and embed itself in the coating. Future material development efforts will be aimed at making flexible coatings with some hardness at the coating/air interface to prevent dirt from sticking. Currently, ASTM subcommittee D01.42 is working on publishing a new test method for measuring dirt pickup resistance of architectural coatings.

Another important property for exterior paint is the development of integrity against rain early in the life of the coating, or “early rain resistance.” Exterior painters cannot predict exactly when rainfall will occur. It is desirable to have a coating that will not be damaged or washed away by a rain shower one or two hours after it is applied. This property can be easily tested by exposing painted panels to water streaming from a shower head at a controlled flow rate (Figure 5).

Early rain resistance is achieved by creating a coating that coalesces quickly and accelerates water leaving the film. Usually this property comes at the expense of dry time: a coating that has early rain resistance will become dry to touch very quickly.

VOC-Compliant Oil-Based Materials

Despite the recent trend to waterborne coatings, there are some applications in which oil-based materials are still preferred. For those who want the look and feel of an oil-based wood stain for their deck or gazebo, these materials offer the advantages of good penetration into the wood as well as a water-repelling effect. In general, they need to be re-applied every year or two.

However, these materials are generally very high in VOC and only allowed, in their traditional form, in 33 states. Today product developers are working with low volatility oils and oil derivatives that can provide acceptable application viscosity with less reducing solvent. In some cases, exempt solvents can be used to allow viscosity reduction without adding to the VOC value.

Reduction of VOC of the finished product to 275 g/L allows it to be sold in most areas of the United States, although the South Coast Air Quality Management District of California requires 100 g/L. Similar to the paint analogs, the lowering of VOC in these products presents some challenges as return-to-service time (due to long dry time) and dirt pickup resistance (Figure 6) can be compromised.

New Looks

It is possible to produce many novel, eye-catching looks by using special paint application techniques. Faux finish and glaze techniques have been around for many years. Distressed looks which give the appearance of a rusted surface or a tarnished metal are popular. It is possible, with some practice, to become proficient at applying such looks to a wall. In addition, there are many contractors in the market offering professional application of these looks. However, for the average do-it-yourself painter, achieving these looks may require too much skill or artistic talent, and many homeowners are not willing to take on such a project.

Therefore, one of the challenges for today’s paint manufacturers is to develop products that can provide new looks (as opposed to a single, homogeneous color) with a very simple and easy application process. One very appealing product which has gained some traction in China is “multicolor paint,” which mimics the look of natural stone such as granite or marble. Such coatings are made by producing a product that has individual domains of color which do not mix with each other. When sprayed over a base color, the final finish has an appearance of natural stone. Today this look can only be achieved by spraying, but a version that could be applied with a paint roller would be more suitable to the average do-it-yourselfer who may not be willing to use spray equipment. Figure 7 shows a prototype of a roller-applied multicolor paint.

Another way of achieving a new look is to incorporate some type of larger colored particles into a paint formulation. There are a variety of available raw materials that can be used for this purpose. In general, they need to be larger in diameter than the film thickness of the dried paint so that they are visible after the job is finished. By using various types and sizes of colored particles, a variety of effects can be achieved. Again, this type of coating can be applied by spray or roll application, although most homeowners will prefer to use a roller. The texture arising from the larger particles is useful for providing an aesthetically appealing, non-slip surface to concrete walkways and patios. Figure 8 shows a close up view of such a coating, illustrating the texture achieved via the use of large particle flakes.

In Figure 9, one can observe the appearance improvement resulting from the application of this type of coating to the aged concrete on a pool deck.

Summary

The architectural coatings industry has enjoyed a period of healthy innovation over the last decade. A few of the key drivers have been the conversion from oil-based to waterborne paint, VOC reduction, removal of chemicals of concern, the emergence of paint-and-primer-in one products, the desire to provide improved film properties such as dirt pickup resistance and early rain resistance, and the desire to provide easy-to-apply new looks. Coatings formulation continues to be a field rich in innovation. As consumer tastes change, regulatory rules change and new raw materials become available, paint formulators will continue to use their expertise and creativity to produce new products.

References

1. ACA Industry Market Analysis 9th Edition, Chemquest; American Coatings Association, 2015; Ch. 7, p 11.

2. California Air Resources Board web site. http://www.arb.ca.gov/coatings/arch/voclimits.htm

3. South Coast Air Quality Management District web site http://www.aqmd.gov/home/regulations/compliance/architectural-coatings

4. Ozone Transport Commission web site. http://www.otcair.org/

5. Lake Michigan Air Directors Consortium web site. http://www.ladco.org/about/

6. Utah Department of Environmental Quality web site. http://www.deq.utah.gov/FactSheets/fspages/consumerproducts.htm

7. Maricopa County web site. https://www.maricopa.gov/aq/divisions/planning_analysis/AdoptedRules.aspx

8. Environment Canada web site. http://www.ec.gc.ca/lcpe-cepa/eng/regulations/detailReg.cfm?intReg=117

9. SCAQMD web site. http://www.aqmd.gov/docs/default-source/planning/architectural-coatings/current-activities-support-documents/2015_9_par1113_pcm.pdf?sfvrsn=6

10. TFL web site. http://www.tfl.com/web/files/Statement_NPE-surfactants.pdf

11. Wikipedia web site. https://en.wikipedia.org/wiki/Nonylphenol

12. Brown, S. Achieving Successful Microbial Protection While Staying Below EUH208 Limits. Proceedings of the European Coatings Conference, Nuremberg, Germany, April 20-21, 2015.

13. United States Environmental Protection Agency web site. http://www2.epa.gov/sites/production/files/2014-04/documents/pr2000-1.pdf