S.P. Van Remortel, R.E. Ratcliff, D.D. Kragten, Unimin Corporation01.06.17

Abstract

Nepheline syenite, a durable, commonly employed hard feldspathic, is a crystalline silica-free functional filler used in all types of decorative, industrial, and OEM coating applications. Previous research and mineral processing advancements showed that new ultrafine grades have superior optics at high loadings, contribute to improved mechanical properties, and assist UV curing in aqueous UV-cure clear PUD systems. This paper builds on these previous findings using advanced FTIR techniques to better quantify the contributions that affect UV cure rate. Moreover, this paper demonstrates the ability of ultrafine nepheline syenite to reduce formulation costs by replacing part of the expensive photoinitiators and resins without compromising coating performance.

Introduction

Nepheline syenite is a silica-deficient functional filler and additive widely employed in a variety of polymer-filled coating, adhesive, ink, and colorant applications. Micronized sizes are valued for purity of color, gloss control, ease of dispersion with minimal viscosity build, surface property modification, and superior durability. Nepheline syenite is composed of three minerals: soda and potash feldspars, and the mineral nepheline. Although deficient in crystalline silica, nepheline syenite otherwise provides physical performance properties which match ground silica fillers. Since nepheline syenite functional fillers are naturally derived, and deficient in free silica and heavy or transition metals, they are typically less burdened by regulatory requirements such as REACH, RoHS, and TSCA.

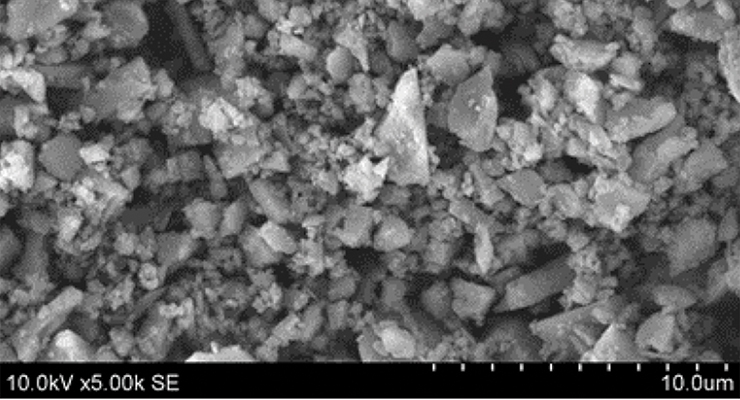

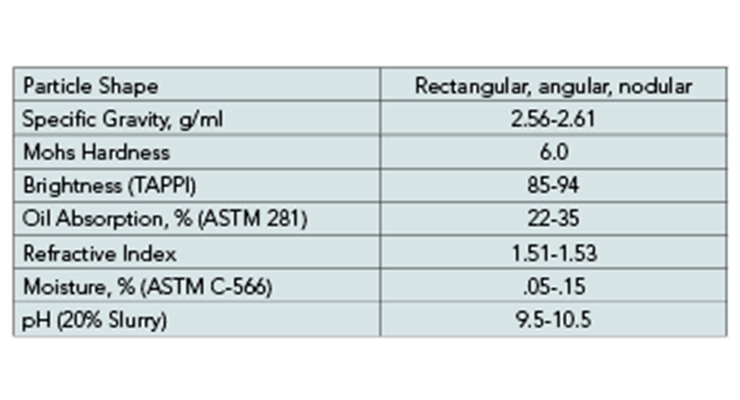

Figure 1 shows the typical particle size and shapes of ultrafine nepheline syenite. Table 1 lists the typical properties of nepheline syenite. Nepheline syenite is considered a moderate gloss reducer based on its low oil absorption and combination of angular, rectangular, and nodular shapes. Mohs hardness on the 1 to 10 scale is about 6. The particles themselves are moderately hard or rigid, and possess high compressive strength providing scratch and abrasion resistance in the polymer matrix. The low oil absorption and alkali aluminosilicate surface chemistry contribute to the ease of wetting and rapid dispersion with low viscosity build.

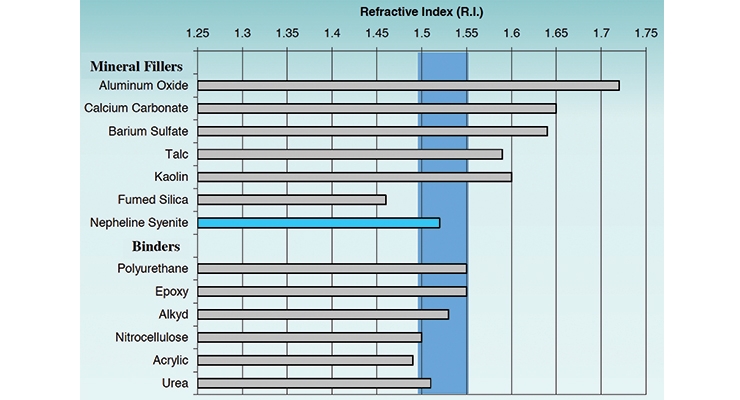

The essential physical property of nepheline syenite that provides high clarity in clear UV-cured resins is the ideal match in Refractive Index (R.I.) with that of the resins. The R.I. of nepheline syenite is compared with the R.I. for several resin systems and other common mineral fillers in Figure 2. The R.I. for nepheline syenite is in the range of 1.50 to 1.53, matching several types of resin systems and oligomers used for radiation curing. Nepheline syenite’s R.I. matches particularly well with acrylic, urea, and urethane monomers and oligomers for exceptional clarity when properly wet out and dispersed in the host binder system.

Previous investigations showed that ultrafine nepheline syenite has exceptionally high light transmittance in organic binder systems commonly used for radiation curing in the critical UVA and UVB wavelengths.1 Thus, unlike other mineral fillers and pigments, ultrafine nepheline syenite is not expected to interfere with the UV curing process.

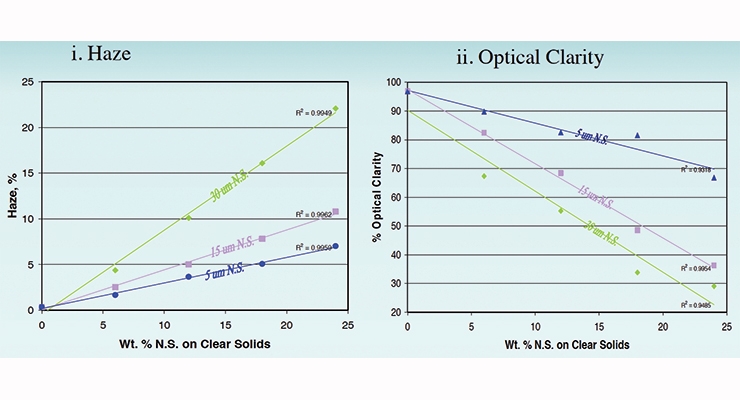

Additionally, it was discovered that nepheline syenite, with sufficiently controlled particle top-size (i.e., D99 < 5 µm), not only maintains, but enhances key properties in radiation-curable clear coatings, such as optical clarity, image clarity, % haze, scratch resistance and gloss, when compared to conventional sizes (i.e., D99 <30 µm) of nepheline and other mineral fillers.1 An illustration of the improved optics and relationship to particle top-size is found in Figures 3a and b. The quality, clarity, and warmth of a UV-cured high-solids acrylic topcoat, applied over stained and sealed maple veneer, filled at 10% with nepheline syenite with a top-size of 5 microns (5 µm N.S.), is shown in Figure 4.

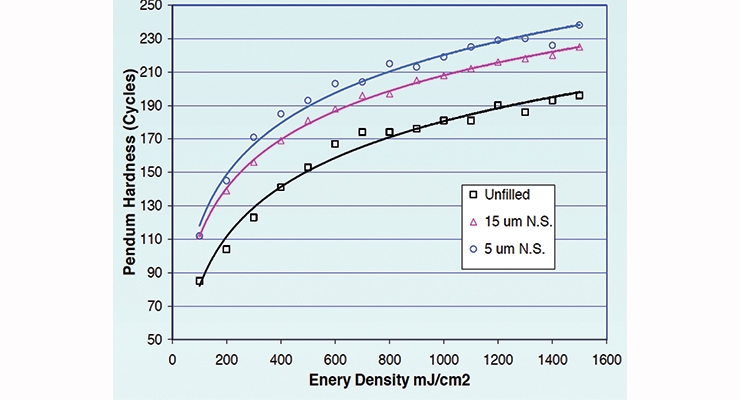

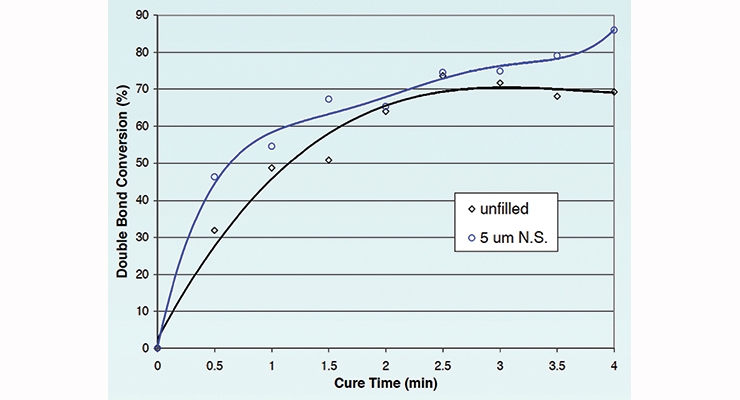

Furthermore, initial testing by UV coating producers and contract labs with nepheline syenite fillers in UV-cured formulations indicated that ultrafine prototypes could have a positive impact on hardness and cure rate. Further experiments measuring pendulum hardness and % double bond conversion of filled films while regulating the cure energy showed that ultrafine nepheline actually improved cure rates.1 This is illustrated in Figures 5a and 5b, respectively. Improved cure rates by filler addition opens up the possibility for greater line speeds or reduced energy requirements simply by adding ultrafine nepheline syenite to the system.

Experimental

Previous experiments noted above confirmed that ultrafine nepheline syenite has a positive effect on cure rate and film hardness in UV-cure PUD systems as opposed to unmodified systems using indirect measures. To better investigate the real-time curing behavior of ultrafine nepheline syenite, the effects of loading level and varying film thickness, and the potential to reduce the required amount of costly photoinitiators, an improved analytical technique was required.

UV-Cure PUD Test Formulations

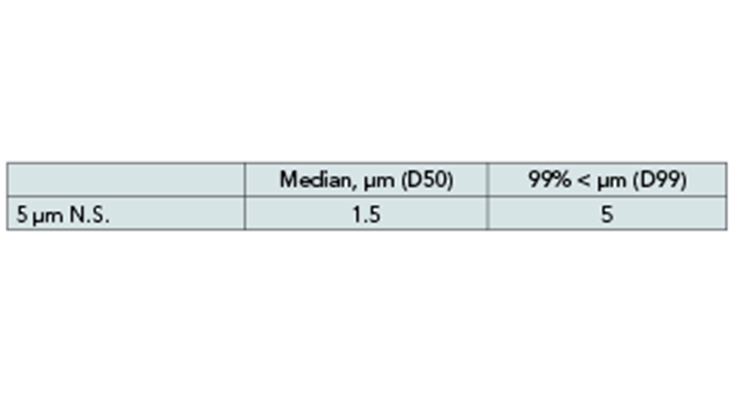

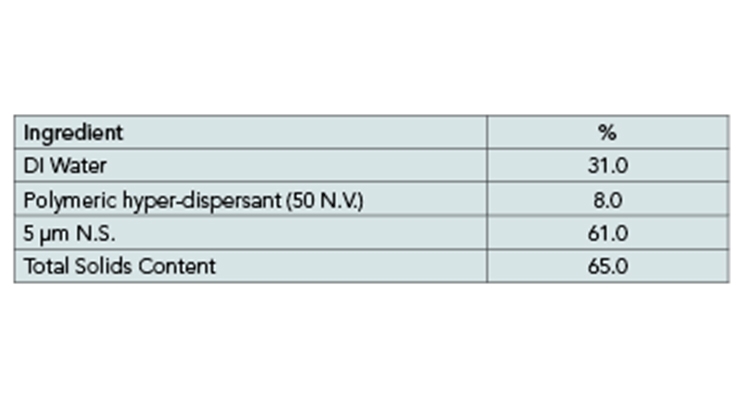

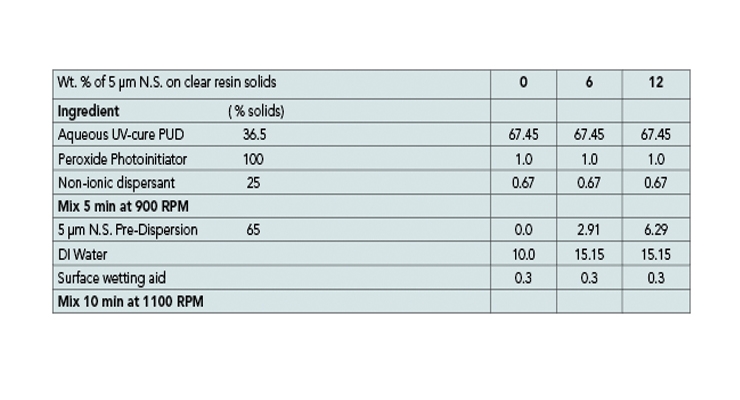

The particle size statistics for ultrafine nepheline syenite (5 µm N.S.) used in the experiments are found in Table 2. The 5 µm N.S. was first incorporated into a stable resin-free pre-dispersion found in Table 3 so it could be added directly to test formulations. The UV-cure PUD test formulations used in this investigation are found in Table 4. The photoinitiator selected for this study functions optimally at higher UV wavelengths of 360 to 440 nm to match the energy of the LED UV light source used for curing.

Cure Rate Determination

A Dymax DX-1000 Visicure Spot was utilized to cure the samples during testing in the FTIR spectrometer. This UV spot curer has a peak wavelength of 405 nm. The spot curer power can be set from 0 to 100% and is fed via fiber optic cable to the area to be cured. This high-intensity source provides virtually instantaneous and controlled power output, making it particularly suitable for measuring real-time cure rates.

The test formulations were applied to Leneta release charts (form RC-5C) with a wire wound bar at the specified wet thickness. The coatings were allowed to air dry for 10 minutes, followed by 10 minutes at 50 ºC. A small section of the coating was scored with a razor blade, then peeled off the release chart using scotch tape. The coating was then attached to a metal holder with tape for measurement using FTIR.

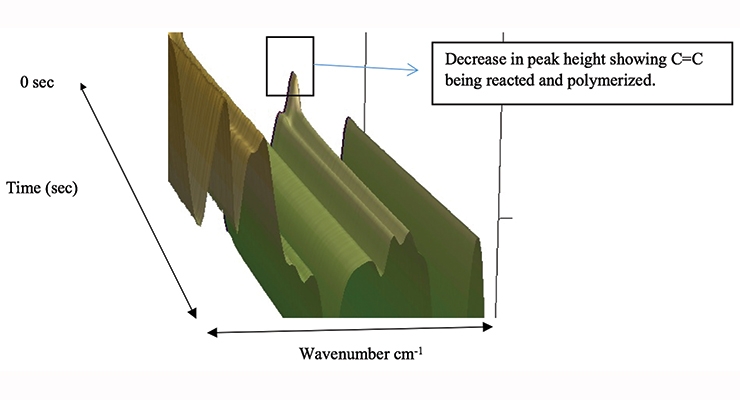

The curing reaction was measured with a Bruker Vertex 70 FTIR in rapid scan mode. A typical 3-D plot of the spectrum for the area of interest can be found in Figure 6. The resolution for testing was set at 8 cm-1 and measured from 1800 to 600 cm-1 with the liquid N2 MCT detector and a 0.5 mm aperture. Approximate scan time was about one minute in which a total of 750 measurements were performed.

Curing was followed by taking the FTIR band area of the reacting resin carbon-carbon double bond (C=C, 800-820 cm-1) and normalizing with a band of the resin that does not change during curing (825-845 cm-1). The cure rate was determined by measuring the time required to react half of the available C=C (t1/2), where complete curing is taken as the intensity of the C=C band after exposure to UV radiation for the full one minute.

5 µm N.S. Loading and Photo-initiator Interaction via DOE

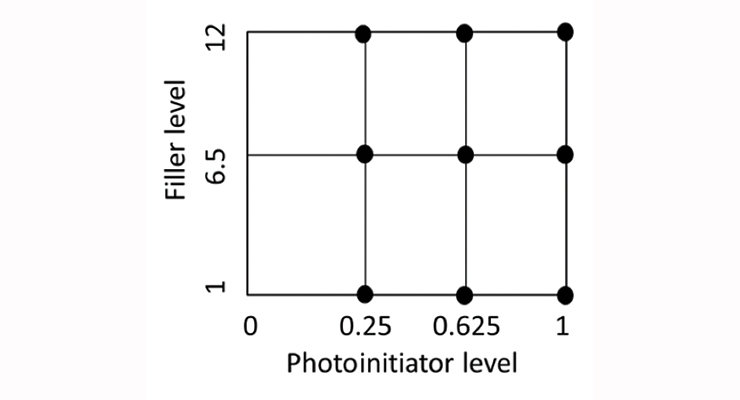

A design of experiments (DOE) was employed to determine the effects of loading levels of 5 µm N.S. and photoinitiator on the cure rate of the UV-cure PUD test formulation. The DOE was set up using statistical software as a multifactorial design with two factors and one response. The two factors studied in the DOE were loading levels of photoinitiator (g) and of 5 µm N.S. (% solids in cured film). The response was t1/2, which is the time required to react half of the available C=C in seconds, and is expressed as the desirability level. A desirability of 1 is ideal, as it represents the lowest cure time for t1/2. The fastest t1/2 was typically around 0.5 seconds. A desirability of 0 represented the slowest t1/2 and was typically around 1.5 seconds. A diagram illustrating this DOE can be found in Figure 7. This DOE was run in triplicate, producing 27 separate measurements.

The cure rate was determined by measuring the time required to react half of the available C=C (t1/2), where completed curing is taken as the intensity of the C=C band after exposure to UV radiation for one minute. The total degree to which the coatings were cured could be determined by analyzing the amount of this band remaining at the end of curing. The degree of curing, or crosslinking, is expected to have a substantial effect on coating properties such as hardness and flexibility.

Assignment of the C=C bands in the FTIR spectra of the urethane acrylate resin was based on comparison with other spectra. Good agreement was found with spectra of various methacrylate resins published on the NIST Chemistry Webbook.2 The vibrational modes of the vinyl moiety can be assigned by comparison with the well-known assignments of the vibrational spectrum of ethylene. FTIR bands at 800-820 and 1400-1410 cm-1 are both due to C-H bending modes of the vinyl moiety of the acrylate.3 Two bands in the FTIR spectra at approximately 800 and 1400 cm-1 were used to determine the cure rates of the testing coatings. The 1400 cm-1 band was relatively stronger than the band at 800 cm-1 and could potentially be used to consider other filler types that might otherwise interfere with the 800 cm-1 band.

Results and Discussion

The first series of experiments studied the kinetics of the UV curing reaction as affected by factors of applied film thickness, 5 µm N.S. filler loadings levels, and photoinitiator levels (100% and 50% levels). Of most interest was the effect of ultrafine nepheline syenite curing behavior in filled, UV-cure PUD clear versus a typical unmodified formulation.

As previously noted, the time required to react half of the available C=C is presented as a measure of cure rate, which occurs in the first couple of seconds after the UV source is turned on. Additional curing up to 60 seconds drives the reaction forward and increases crosslinking density, resulting in a thoroughly cured coating.

Filler Loading Level

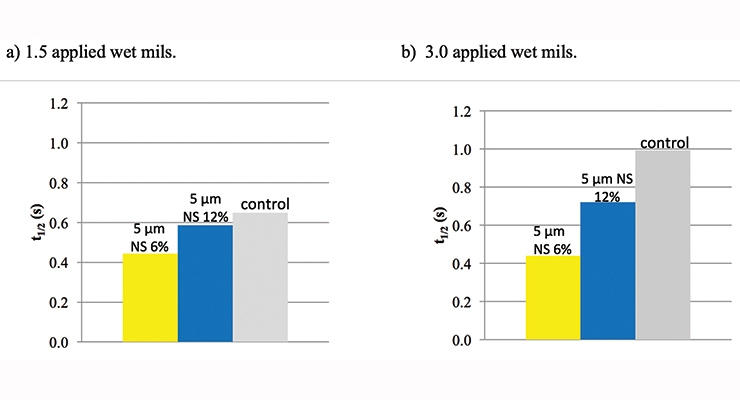

The cure rate results for 5 µm N.S. filled systems versus the unmodified control are presented in Figures 8a and 8b at 1.5 and 3.0 wet film thickness, respectively. When looking at the 3.0 mil films, the 5 µm N.S. filler loading had a faster cure rate at 6% than at 12% loading. Both films cured faster than the unfilled film. This shows that 5 µm N.S. accelerates the initial cure rate relative to the unfilled formulation. Moreover, there appears to be an optimal loading level of 5 µm N.S. to accelerate the curing time.

At 1.5 mil wet thickness, the effect of the 5 µm N.S. loading level on cure rate is smaller, but still observable. It should be noted that the cure rate at 6% did not change much with film thickness. However, the cure rate was much faster than the thinner film loaded at 12% and the unfilled control. The data suggests that 5 µm N.S. could be even more beneficial for curing at greater film thickness.

Photoinitiator Level

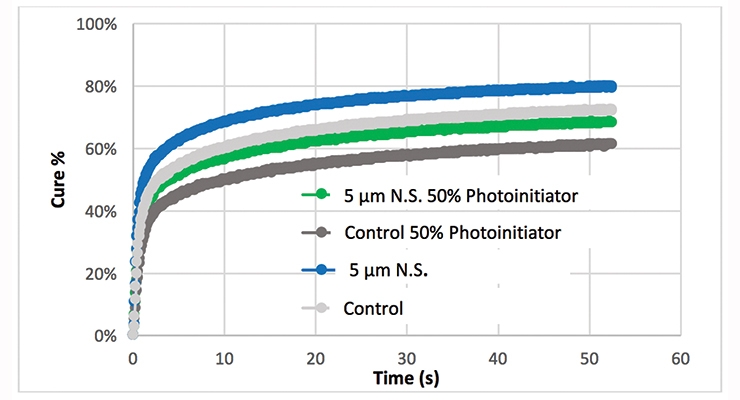

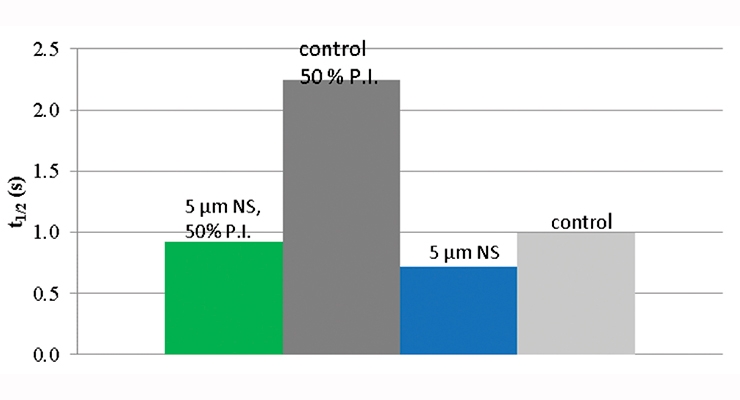

The second series of FTIR experiments studied the effect of 5 µm N.S. on cure rate of formulations with a 50% reduced concentration of the photoinitiator. The results shown above suggested that nepheline syenite acts as a UV cure catalyst by an unknown mechanism. The results for testing at standard and at 50% reduced photoinitiator levels were measured as percentage cured versus time. The plotted functions are found in Figure 9. Time for initial cure (50% C=C conversion) is found in Figure 10. Reducing the photoinitiator level by 50% in the unmodified control has a significant negative effect on the initial cure rate and cure profile. However, when using 12% 5 µm N.S. in the coating with 50% lower photoinitiator, the cure decreased only slightly. Again, the initial cure rate with 5 µm N.S. provides a superior and accelerated curing profile versus the unmodified control, and more thorough cure after one minute.

DOE: 5 µm N.S. and Photoinitiator Impact on Cure

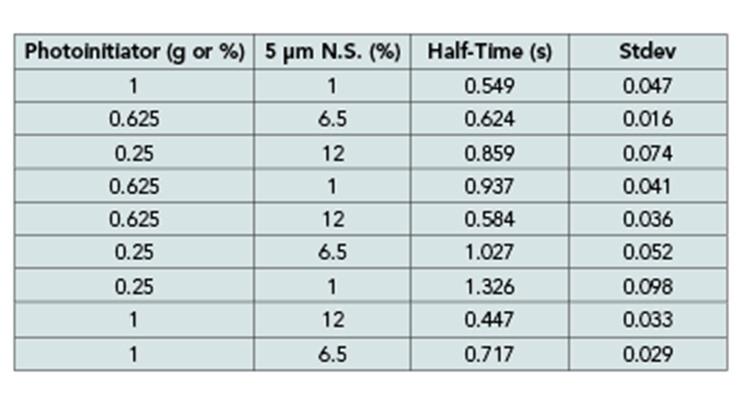

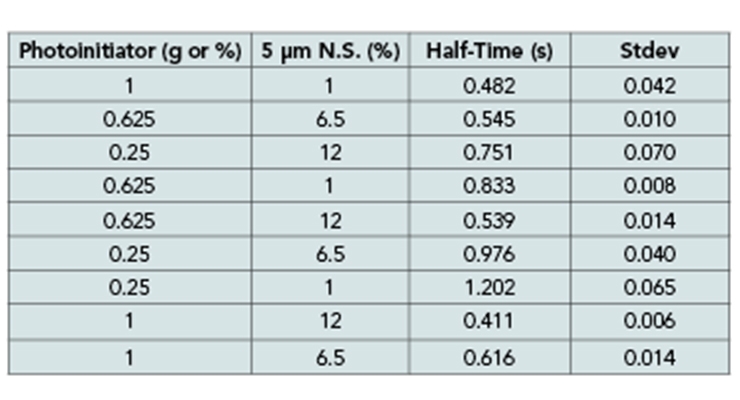

To further study the effect of 5 µm N.S. on radiation curing and interactions with the photoinitiator, a design of experiments (DOE) was conducted. The design parameters and results of these measurements are listed in Tables 5 and 6. The standard deviation in the curing rate, as expressed by the half–time, is approximately 10%. The error analysis for each FTIR measurement band showed the R2 or correlation values both exceeded 90%, which is excellent for this model and shows a high level of correlation and confidence in the predictions.

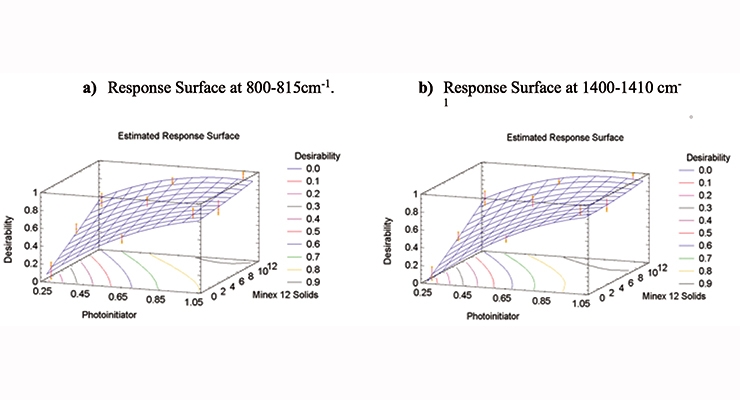

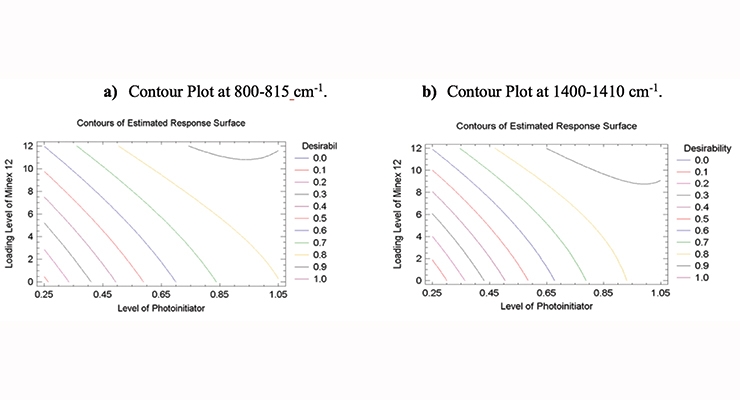

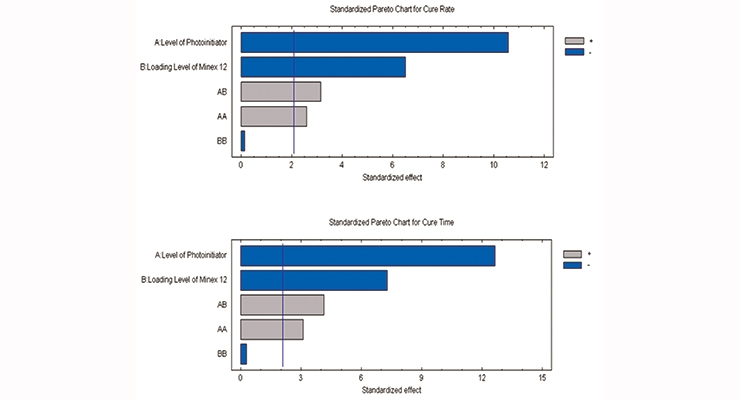

With the aid of statistical graphing software, the contributions of 5 µm N.S. and photoinitiator to the curing rate were compared with response surface plots, contour plots, and Pareto charts. The response surface plots are useful to show the correlation of the two factors (5 µm N.S. and photoinitiator) with the response (t1/2). The contour plot is useful to make predictions of the cure time based on 5 µm N.S. and photoinitiator loading levels. The Pareto chart determines the importance of each factor in the response.

The response surface plots for the DOE for each band (800-810 cm-1 and 1400-1410 cm-1) can be found in Figures 11a and b. A desirability of 1 is ideal, as it represents the fastest, or lowest, cure time for t1/2. The response plots show a large correlation between the level of photoinitiator and the cure rate, which is expected. To a lesser degree, the amount of 5 µm N.S. influences cure rate. For each FTIR band, both surfaces are almost identical, confirming that both represent the same chemical conversion.

Contour plots for the response surfaces are shown in Figures 12a and b. These plots predict the possibility of reduction in photoinitiator in combination with the use of 5 µm N.S. For example, at desirability of 0.5, or approximately a t1/2 of 0.8 seconds, a loading level of 6% solids of 5 µm N.S. could help reduce the photoinitiator level by almost 20%. For large scale production lines, this reduction could be substantial. To achieve the fastest cure, the photoinitiator can be reduced by the same amount at a loading level of 12% 5µm N.S.

The Pareto charts for each band can be found in Figure 13. Pareto charts illustrate the importance of each factor being studied. The standardized effect is the absolute value for that factor and includes a reference line. Effects beyond this line can be considered potentially important. The level of photoinitiator is the most important factor; however, a loading level of 5 µm N.S. also has a significant effect on the curing time.

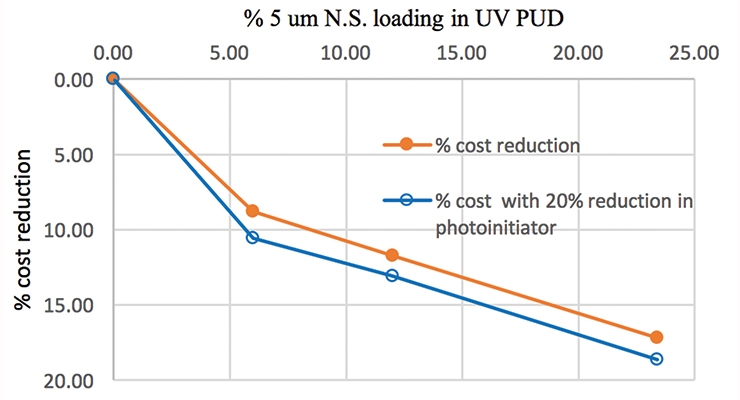

Economic Considerations with Synergistic Ultrafine Nepheline Syenite

An important factor in the formulation of commercial UV-cure coatings is the raw material costs. One of the main benefits of a natural mineral filler suitable for use in clear UV-cure formulations is the much lower cost compared with that of the resin. Fillers typically cost on the order of ten to twenty times less. This suggests that adding 5 µm N.S. at 5% by weight on resin solids will reduce the formulation cost by approximately 5%. Adding 10% by weight will reduce applied film cost by 10%; 15 % addition equals 15% reduction in cost, and so forth. The cost analysis for the UV-cure test formulations are provided in Figure 14.

Additionally, it was shown that 5 µm N.S. has a synergistic effect with the photoinitiator, allowing the system to maintain cure with a lower percentage of photoinitiator in the system on the order of 10-20%. The ability to lower the amount of photoinitiator by 10-20% at any given loading level can lower the formulation cost by an additional 1-2%. In thin film UV-cured applications like OPV and inks, the potential to load 5 µm N.S. as high as 20-25% is realistic. Of course the maximum allowable filler loading depends on the applied film thickness and haze and clarity tolerances in a given application.

Conclusion

Nepheline syenite is a versatile and unique functional filler, possessing properties that are useful in a wide variety of clear and opaque coating applications. Ultrafine nepheline syenite has a refractive index and physical properties that are particularly well-suited for enhancing performance in radiation curable coatings, inks, and adhesives.

Using real-time FTIR analysis, the effect of ultrafine nepheline syenite on curing rate was evaluated. It was found that ultrafine nepheline syenite accelerates cure rate in UV-cure PUD coatings at any loading level and applied film thickness, and can potentially replace 10-20% of the photoinitiator. The DOE study confirmed that the peroxide photoinitiator level is the most important factor in determining cure rate, which was expected, and that the level of 5 µm N.S. is also an important factor.

Additionally, highly transparent and functional fillers like ultrafine nepheline syenite are an excellent tool for lowering formulating cost, while enhancing mechanical performance and ensuring excellent and non-interfering UV-curing behaviors. Future investigation will consider the mechanism by which ultrafine nepheline syenite enhances the UV curing behavior. The potential for other natural ultrafine hard silica and silicate fillers, with low and different R.I. properties, to provide similar or enhanced properties in UV coatings will be explored.

References

(1) Van Remortel. S., Ratcliff. R. “Ultrafine Nepheline as a Durable and Transparent Additive to Accelerate Radiation Cure. RadTech, May 2010.

(2) NIST Chemistry Webbook, NIST standard reference database number 69, webbook.nist.gov/chemistry.

(3) Ethylene has vibrational modes at 835 cm-1 and 1413 cm-1 due to H-C-H in-plane rocking and H-C-C in-plane scissoring, respectively.

This paper was presented at RadTech 2016, Chicago, IL.

Nepheline syenite, a durable, commonly employed hard feldspathic, is a crystalline silica-free functional filler used in all types of decorative, industrial, and OEM coating applications. Previous research and mineral processing advancements showed that new ultrafine grades have superior optics at high loadings, contribute to improved mechanical properties, and assist UV curing in aqueous UV-cure clear PUD systems. This paper builds on these previous findings using advanced FTIR techniques to better quantify the contributions that affect UV cure rate. Moreover, this paper demonstrates the ability of ultrafine nepheline syenite to reduce formulation costs by replacing part of the expensive photoinitiators and resins without compromising coating performance.

Introduction

Nepheline syenite is a silica-deficient functional filler and additive widely employed in a variety of polymer-filled coating, adhesive, ink, and colorant applications. Micronized sizes are valued for purity of color, gloss control, ease of dispersion with minimal viscosity build, surface property modification, and superior durability. Nepheline syenite is composed of three minerals: soda and potash feldspars, and the mineral nepheline. Although deficient in crystalline silica, nepheline syenite otherwise provides physical performance properties which match ground silica fillers. Since nepheline syenite functional fillers are naturally derived, and deficient in free silica and heavy or transition metals, they are typically less burdened by regulatory requirements such as REACH, RoHS, and TSCA.

Figure 1 shows the typical particle size and shapes of ultrafine nepheline syenite. Table 1 lists the typical properties of nepheline syenite. Nepheline syenite is considered a moderate gloss reducer based on its low oil absorption and combination of angular, rectangular, and nodular shapes. Mohs hardness on the 1 to 10 scale is about 6. The particles themselves are moderately hard or rigid, and possess high compressive strength providing scratch and abrasion resistance in the polymer matrix. The low oil absorption and alkali aluminosilicate surface chemistry contribute to the ease of wetting and rapid dispersion with low viscosity build.

The essential physical property of nepheline syenite that provides high clarity in clear UV-cured resins is the ideal match in Refractive Index (R.I.) with that of the resins. The R.I. of nepheline syenite is compared with the R.I. for several resin systems and other common mineral fillers in Figure 2. The R.I. for nepheline syenite is in the range of 1.50 to 1.53, matching several types of resin systems and oligomers used for radiation curing. Nepheline syenite’s R.I. matches particularly well with acrylic, urea, and urethane monomers and oligomers for exceptional clarity when properly wet out and dispersed in the host binder system.

Previous investigations showed that ultrafine nepheline syenite has exceptionally high light transmittance in organic binder systems commonly used for radiation curing in the critical UVA and UVB wavelengths.1 Thus, unlike other mineral fillers and pigments, ultrafine nepheline syenite is not expected to interfere with the UV curing process.

Additionally, it was discovered that nepheline syenite, with sufficiently controlled particle top-size (i.e., D99 < 5 µm), not only maintains, but enhances key properties in radiation-curable clear coatings, such as optical clarity, image clarity, % haze, scratch resistance and gloss, when compared to conventional sizes (i.e., D99 <30 µm) of nepheline and other mineral fillers.1 An illustration of the improved optics and relationship to particle top-size is found in Figures 3a and b. The quality, clarity, and warmth of a UV-cured high-solids acrylic topcoat, applied over stained and sealed maple veneer, filled at 10% with nepheline syenite with a top-size of 5 microns (5 µm N.S.), is shown in Figure 4.

Furthermore, initial testing by UV coating producers and contract labs with nepheline syenite fillers in UV-cured formulations indicated that ultrafine prototypes could have a positive impact on hardness and cure rate. Further experiments measuring pendulum hardness and % double bond conversion of filled films while regulating the cure energy showed that ultrafine nepheline actually improved cure rates.1 This is illustrated in Figures 5a and 5b, respectively. Improved cure rates by filler addition opens up the possibility for greater line speeds or reduced energy requirements simply by adding ultrafine nepheline syenite to the system.

Experimental

Previous experiments noted above confirmed that ultrafine nepheline syenite has a positive effect on cure rate and film hardness in UV-cure PUD systems as opposed to unmodified systems using indirect measures. To better investigate the real-time curing behavior of ultrafine nepheline syenite, the effects of loading level and varying film thickness, and the potential to reduce the required amount of costly photoinitiators, an improved analytical technique was required.

UV-Cure PUD Test Formulations

The particle size statistics for ultrafine nepheline syenite (5 µm N.S.) used in the experiments are found in Table 2. The 5 µm N.S. was first incorporated into a stable resin-free pre-dispersion found in Table 3 so it could be added directly to test formulations. The UV-cure PUD test formulations used in this investigation are found in Table 4. The photoinitiator selected for this study functions optimally at higher UV wavelengths of 360 to 440 nm to match the energy of the LED UV light source used for curing.

Cure Rate Determination

A Dymax DX-1000 Visicure Spot was utilized to cure the samples during testing in the FTIR spectrometer. This UV spot curer has a peak wavelength of 405 nm. The spot curer power can be set from 0 to 100% and is fed via fiber optic cable to the area to be cured. This high-intensity source provides virtually instantaneous and controlled power output, making it particularly suitable for measuring real-time cure rates.

The test formulations were applied to Leneta release charts (form RC-5C) with a wire wound bar at the specified wet thickness. The coatings were allowed to air dry for 10 minutes, followed by 10 minutes at 50 ºC. A small section of the coating was scored with a razor blade, then peeled off the release chart using scotch tape. The coating was then attached to a metal holder with tape for measurement using FTIR.

The curing reaction was measured with a Bruker Vertex 70 FTIR in rapid scan mode. A typical 3-D plot of the spectrum for the area of interest can be found in Figure 6. The resolution for testing was set at 8 cm-1 and measured from 1800 to 600 cm-1 with the liquid N2 MCT detector and a 0.5 mm aperture. Approximate scan time was about one minute in which a total of 750 measurements were performed.

Curing was followed by taking the FTIR band area of the reacting resin carbon-carbon double bond (C=C, 800-820 cm-1) and normalizing with a band of the resin that does not change during curing (825-845 cm-1). The cure rate was determined by measuring the time required to react half of the available C=C (t1/2), where complete curing is taken as the intensity of the C=C band after exposure to UV radiation for the full one minute.

5 µm N.S. Loading and Photo-initiator Interaction via DOE

A design of experiments (DOE) was employed to determine the effects of loading levels of 5 µm N.S. and photoinitiator on the cure rate of the UV-cure PUD test formulation. The DOE was set up using statistical software as a multifactorial design with two factors and one response. The two factors studied in the DOE were loading levels of photoinitiator (g) and of 5 µm N.S. (% solids in cured film). The response was t1/2, which is the time required to react half of the available C=C in seconds, and is expressed as the desirability level. A desirability of 1 is ideal, as it represents the lowest cure time for t1/2. The fastest t1/2 was typically around 0.5 seconds. A desirability of 0 represented the slowest t1/2 and was typically around 1.5 seconds. A diagram illustrating this DOE can be found in Figure 7. This DOE was run in triplicate, producing 27 separate measurements.

The cure rate was determined by measuring the time required to react half of the available C=C (t1/2), where completed curing is taken as the intensity of the C=C band after exposure to UV radiation for one minute. The total degree to which the coatings were cured could be determined by analyzing the amount of this band remaining at the end of curing. The degree of curing, or crosslinking, is expected to have a substantial effect on coating properties such as hardness and flexibility.

Assignment of the C=C bands in the FTIR spectra of the urethane acrylate resin was based on comparison with other spectra. Good agreement was found with spectra of various methacrylate resins published on the NIST Chemistry Webbook.2 The vibrational modes of the vinyl moiety can be assigned by comparison with the well-known assignments of the vibrational spectrum of ethylene. FTIR bands at 800-820 and 1400-1410 cm-1 are both due to C-H bending modes of the vinyl moiety of the acrylate.3 Two bands in the FTIR spectra at approximately 800 and 1400 cm-1 were used to determine the cure rates of the testing coatings. The 1400 cm-1 band was relatively stronger than the band at 800 cm-1 and could potentially be used to consider other filler types that might otherwise interfere with the 800 cm-1 band.

Results and Discussion

The first series of experiments studied the kinetics of the UV curing reaction as affected by factors of applied film thickness, 5 µm N.S. filler loadings levels, and photoinitiator levels (100% and 50% levels). Of most interest was the effect of ultrafine nepheline syenite curing behavior in filled, UV-cure PUD clear versus a typical unmodified formulation.

As previously noted, the time required to react half of the available C=C is presented as a measure of cure rate, which occurs in the first couple of seconds after the UV source is turned on. Additional curing up to 60 seconds drives the reaction forward and increases crosslinking density, resulting in a thoroughly cured coating.

Filler Loading Level

The cure rate results for 5 µm N.S. filled systems versus the unmodified control are presented in Figures 8a and 8b at 1.5 and 3.0 wet film thickness, respectively. When looking at the 3.0 mil films, the 5 µm N.S. filler loading had a faster cure rate at 6% than at 12% loading. Both films cured faster than the unfilled film. This shows that 5 µm N.S. accelerates the initial cure rate relative to the unfilled formulation. Moreover, there appears to be an optimal loading level of 5 µm N.S. to accelerate the curing time.

At 1.5 mil wet thickness, the effect of the 5 µm N.S. loading level on cure rate is smaller, but still observable. It should be noted that the cure rate at 6% did not change much with film thickness. However, the cure rate was much faster than the thinner film loaded at 12% and the unfilled control. The data suggests that 5 µm N.S. could be even more beneficial for curing at greater film thickness.

Photoinitiator Level

The second series of FTIR experiments studied the effect of 5 µm N.S. on cure rate of formulations with a 50% reduced concentration of the photoinitiator. The results shown above suggested that nepheline syenite acts as a UV cure catalyst by an unknown mechanism. The results for testing at standard and at 50% reduced photoinitiator levels were measured as percentage cured versus time. The plotted functions are found in Figure 9. Time for initial cure (50% C=C conversion) is found in Figure 10. Reducing the photoinitiator level by 50% in the unmodified control has a significant negative effect on the initial cure rate and cure profile. However, when using 12% 5 µm N.S. in the coating with 50% lower photoinitiator, the cure decreased only slightly. Again, the initial cure rate with 5 µm N.S. provides a superior and accelerated curing profile versus the unmodified control, and more thorough cure after one minute.

DOE: 5 µm N.S. and Photoinitiator Impact on Cure

To further study the effect of 5 µm N.S. on radiation curing and interactions with the photoinitiator, a design of experiments (DOE) was conducted. The design parameters and results of these measurements are listed in Tables 5 and 6. The standard deviation in the curing rate, as expressed by the half–time, is approximately 10%. The error analysis for each FTIR measurement band showed the R2 or correlation values both exceeded 90%, which is excellent for this model and shows a high level of correlation and confidence in the predictions.

With the aid of statistical graphing software, the contributions of 5 µm N.S. and photoinitiator to the curing rate were compared with response surface plots, contour plots, and Pareto charts. The response surface plots are useful to show the correlation of the two factors (5 µm N.S. and photoinitiator) with the response (t1/2). The contour plot is useful to make predictions of the cure time based on 5 µm N.S. and photoinitiator loading levels. The Pareto chart determines the importance of each factor in the response.

The response surface plots for the DOE for each band (800-810 cm-1 and 1400-1410 cm-1) can be found in Figures 11a and b. A desirability of 1 is ideal, as it represents the fastest, or lowest, cure time for t1/2. The response plots show a large correlation between the level of photoinitiator and the cure rate, which is expected. To a lesser degree, the amount of 5 µm N.S. influences cure rate. For each FTIR band, both surfaces are almost identical, confirming that both represent the same chemical conversion.

Contour plots for the response surfaces are shown in Figures 12a and b. These plots predict the possibility of reduction in photoinitiator in combination with the use of 5 µm N.S. For example, at desirability of 0.5, or approximately a t1/2 of 0.8 seconds, a loading level of 6% solids of 5 µm N.S. could help reduce the photoinitiator level by almost 20%. For large scale production lines, this reduction could be substantial. To achieve the fastest cure, the photoinitiator can be reduced by the same amount at a loading level of 12% 5µm N.S.

The Pareto charts for each band can be found in Figure 13. Pareto charts illustrate the importance of each factor being studied. The standardized effect is the absolute value for that factor and includes a reference line. Effects beyond this line can be considered potentially important. The level of photoinitiator is the most important factor; however, a loading level of 5 µm N.S. also has a significant effect on the curing time.

Economic Considerations with Synergistic Ultrafine Nepheline Syenite

An important factor in the formulation of commercial UV-cure coatings is the raw material costs. One of the main benefits of a natural mineral filler suitable for use in clear UV-cure formulations is the much lower cost compared with that of the resin. Fillers typically cost on the order of ten to twenty times less. This suggests that adding 5 µm N.S. at 5% by weight on resin solids will reduce the formulation cost by approximately 5%. Adding 10% by weight will reduce applied film cost by 10%; 15 % addition equals 15% reduction in cost, and so forth. The cost analysis for the UV-cure test formulations are provided in Figure 14.

Additionally, it was shown that 5 µm N.S. has a synergistic effect with the photoinitiator, allowing the system to maintain cure with a lower percentage of photoinitiator in the system on the order of 10-20%. The ability to lower the amount of photoinitiator by 10-20% at any given loading level can lower the formulation cost by an additional 1-2%. In thin film UV-cured applications like OPV and inks, the potential to load 5 µm N.S. as high as 20-25% is realistic. Of course the maximum allowable filler loading depends on the applied film thickness and haze and clarity tolerances in a given application.

Conclusion

Nepheline syenite is a versatile and unique functional filler, possessing properties that are useful in a wide variety of clear and opaque coating applications. Ultrafine nepheline syenite has a refractive index and physical properties that are particularly well-suited for enhancing performance in radiation curable coatings, inks, and adhesives.

Using real-time FTIR analysis, the effect of ultrafine nepheline syenite on curing rate was evaluated. It was found that ultrafine nepheline syenite accelerates cure rate in UV-cure PUD coatings at any loading level and applied film thickness, and can potentially replace 10-20% of the photoinitiator. The DOE study confirmed that the peroxide photoinitiator level is the most important factor in determining cure rate, which was expected, and that the level of 5 µm N.S. is also an important factor.

Additionally, highly transparent and functional fillers like ultrafine nepheline syenite are an excellent tool for lowering formulating cost, while enhancing mechanical performance and ensuring excellent and non-interfering UV-curing behaviors. Future investigation will consider the mechanism by which ultrafine nepheline syenite enhances the UV curing behavior. The potential for other natural ultrafine hard silica and silicate fillers, with low and different R.I. properties, to provide similar or enhanced properties in UV coatings will be explored.

References

(1) Van Remortel. S., Ratcliff. R. “Ultrafine Nepheline as a Durable and Transparent Additive to Accelerate Radiation Cure. RadTech, May 2010.

(2) NIST Chemistry Webbook, NIST standard reference database number 69, webbook.nist.gov/chemistry.

(3) Ethylene has vibrational modes at 835 cm-1 and 1413 cm-1 due to H-C-H in-plane rocking and H-C-C in-plane scissoring, respectively.

This paper was presented at RadTech 2016, Chicago, IL.