04.30.19

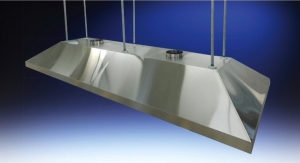

No. 972 is an electrically-heated, 250ºF (120ºC) two-zone belt conveyor oven from Grieve, currently used to cure a coating onto plastic sheets at the customer’s facility.

Workspace dimensions measure 48” W x 50’D x 15” H. 80KW (40KW per zone) are installed in Incoloy sheathed tubular elements to heat the unit, while 25,000 CFM total from two 10-HP recirculating blower motors provides vertical downward airflow to the workload.

The oven’s travel comprises a 36” long open belt loading zone, two 25’ long insulated heating zones with independent recirculated airflow and temperature control, plus a 36” long open belt unloading zone. A 42” wide, 1” x 1” flat wire plastic conveyor belt is driven by a 1/2-HP motor drive, variable from 1-20 feet per minute.

This Grieve conveyor oven features 4” thick insulated walls throughout, an aluminized steel exterior, Type 304, 2B finish stainless steel interior with continuously back-welded seams and all wall penetrations fitted with compression fittings. The oven is split into two sections for shipment and reassembly at the customer’s location. Side access doors to the workload and heating chambers are located along the entire length of the unit.

Controls on No. 972 include digital indicating temperature controllers, manual reset excess temperature controllers with separate contactors, recirculating blower airflow safety switches, 10” diameter, two-pen circular chart temperature recorders and SCR power controllers for the heating zones.