09.09.19

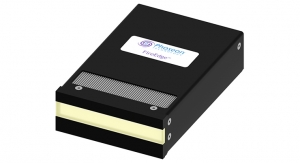

Phoseon Technology is introducing the FireJet FJ645 UV LED self-contained, air-cooled curing lamp for flexographic applications at Labelexpo Europe 2019 in Brussels, Belgium.

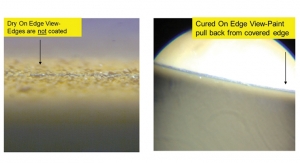

With a 40mm wide emitting window, the FJ645 provides longer UV exposure time and greater dose, improving through-cure and adhesion of difficult to cure materials; especially over-print varnishes, and dense blacks. The increased dose allows for higher speed without the need for additional facilities requirements, such as exhaust blowers or water chillers.

The FJ645 is designed for press manufacturers and converters looking for market-leading performance and digital control. It is ideal for applications that require more dose and dwell time for better surface, depth cure and adhesion. The FJ645 is available in print widths up to 525mm and includes advanced digital interface capabilities for tight process control, such as low-migration processes for food packaging.

“The FJ645 has several advantages over its competitors in the market,” said Sara Jennings, Phoseon’s senior technical marketing engineer. “For example, it’s a high-performance self-contained air-cooled solution that doesn’t require exhaust blowers or water chillers. The wider emitting window allows more dwell time for the ink or coating to absorb more UV energy in one pass. This allows the UV curing process (polymerization) to create longer bonded chains, which improves the strength and through-cure in the material.”

The FJ645 has the performance necessary to increase speed capabilities of market leading presses and is compact enough to retrofit existing installed presses, allowing converters to do more business now.

Also, the FJ645 supports the following patented technology enhancements:

The FJ645 will be available in the fourth quarter of 2019.

With a 40mm wide emitting window, the FJ645 provides longer UV exposure time and greater dose, improving through-cure and adhesion of difficult to cure materials; especially over-print varnishes, and dense blacks. The increased dose allows for higher speed without the need for additional facilities requirements, such as exhaust blowers or water chillers.

The FJ645 is designed for press manufacturers and converters looking for market-leading performance and digital control. It is ideal for applications that require more dose and dwell time for better surface, depth cure and adhesion. The FJ645 is available in print widths up to 525mm and includes advanced digital interface capabilities for tight process control, such as low-migration processes for food packaging.

“The FJ645 has several advantages over its competitors in the market,” said Sara Jennings, Phoseon’s senior technical marketing engineer. “For example, it’s a high-performance self-contained air-cooled solution that doesn’t require exhaust blowers or water chillers. The wider emitting window allows more dwell time for the ink or coating to absorb more UV energy in one pass. This allows the UV curing process (polymerization) to create longer bonded chains, which improves the strength and through-cure in the material.”

The FJ645 has the performance necessary to increase speed capabilities of market leading presses and is compact enough to retrofit existing installed presses, allowing converters to do more business now.

Also, the FJ645 supports the following patented technology enhancements:

- WhisperCure Technology to deliver leading-edge air-cooled performance at reduced decibel levels creating a quieter and safer environment for operators;

- TargetCure Technology delivers fast performance uniformity with the instant on and off capability of LED and reliability of performance over the life of the lamp.

The FJ645 will be available in the fourth quarter of 2019.