Dr. Mouhcine Kanouni and Tobias Niederleitner, Market Manager Coatings, Performance Additives, USA and Global Technical Segment Manager, Advanced Surface Solutions, Germany09.30.19

Coatings in the automotive industry are essential and everywhere. Coatings not only give the body the desired color, but also provide weathering protection to UV-light exposed parts as well as a smooth finish to interior surfaces. Newly developed additives used for light stabilization and surface modification help to enhance the appearance and the durability of these coatings.

Outdoor durability of OEM and refinish topcoats has always been an important focus area throughout the automotive coating industry. The topcoat weathering requirements must meet more and more stringent market standards as coatings technology is evolving as well. However, automotive refinish topcoats have additional challenges, not relevant for the OEM topcoats due to the application processes.

Surely, there is no high-temperature bake for automotive refinish contrary to OEM coatings which restricts the resin technology enormously. Other challenges are found in the form of dust pick up, silicone contamination of the paint booth that would cause fish-eyes in the coating, irregularities in coating thickness due to multiple layer application, and finally the concept of improved in-can color.

UV Filter Properties and In-Can Color

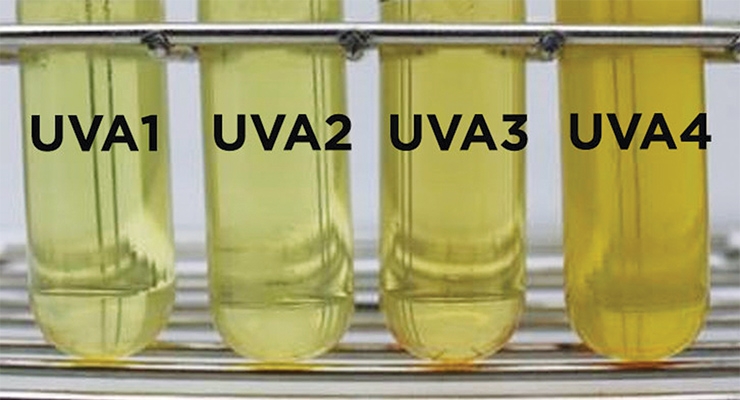

The in-can color of an automotive refinish topcoat can be defined as the color of the clearcoat observed through the can by the paint applicator. This property is well known in the automotive refinish industry and is a challenge in all regions of the world. Applicators will always prefer a low in-can color clearcoat and will very often consider this as a key criteria to select their clearcoat suppliers.

The impact of in-can color on the weathering performance of an automotive topcoat is not intuitive. After all, the main factor influencing the in-can color is the UV absorber component of the topcoat. Indeed, the resins, which are by far the most important components of the topcoat have practically no impact on in-can color contrary to the UV absorber.

In a long-term study Clariant's coatings expert aimed to develop a unique UV absorber solution for automotive refinish clearcoats, enabling an improvement in weathering performance while keeping the paint in-can color at lowest level compared to current market standard.

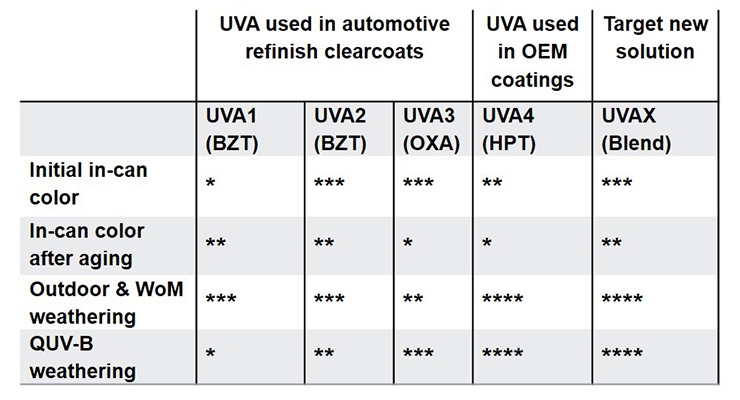

Currently there are three types of UV absorbers used in automotive clearcoats, with each one having its own advantages and disadvantages , (Table 1 and Figure 1).

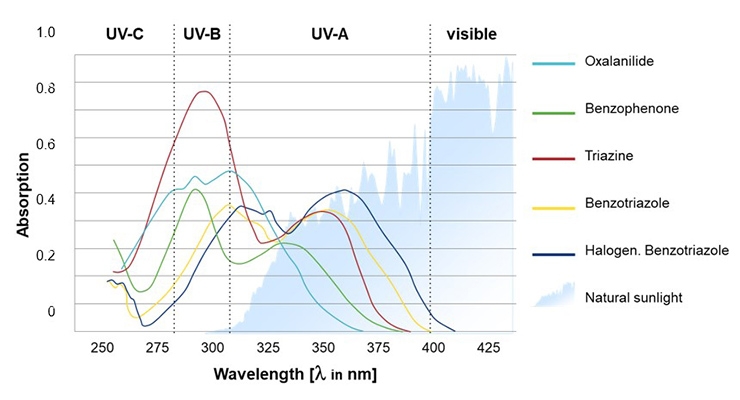

To understand the yellowing impact from each individual UV absorber on the in-can color properties in the formulation, Figure 2 represents the different absorbance curves for each UV absorber.

Referring to Figure 2, in theory oxalanilide UVAs should have the lowest initial color due to their UV absorbance being furthest away from the visible light spectrum (below 375 nm) when compared to other UV Absorbers.

However, referring back to Figure 1, it is clear from UVA4 (triazine) that the rationale of this theory is not supported at all times.

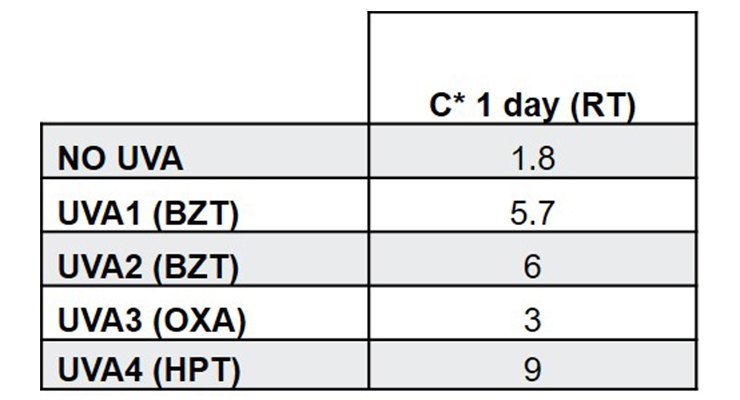

Table 2 refers to C* values, adding additional support to this rationale.

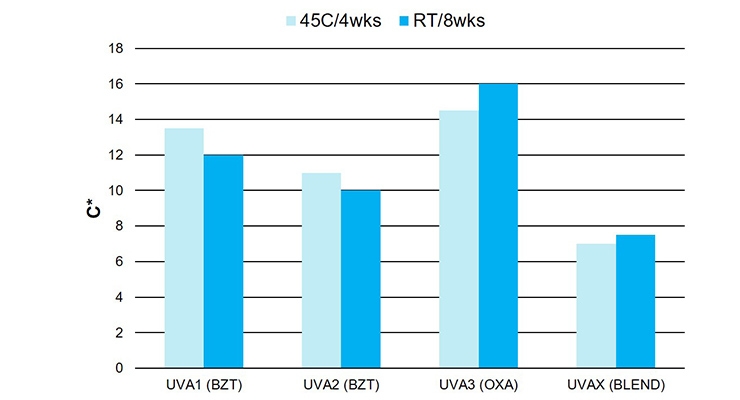

In the study, Clariant developed UVAX, an innovative UV absorber solution that exhibits the best in-can color properties, as is shown in C* measurements in Graph 1.

Weathering Tests

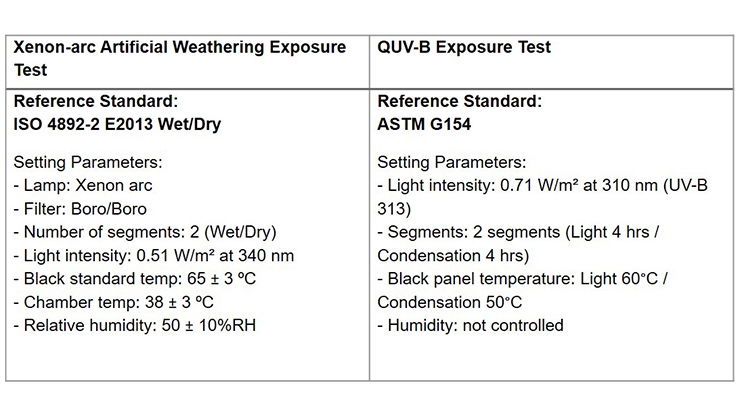

The next step of the study was to determine the weathering performance of the standard UV absorbers in a 2K-PU automotive clearcoat applied over a white basecoat and compare them to the newly developed (not yet commercialized) product UVAX. For the accelerated weathering tests, a xenon-arc artificial weathering instrument and the QUV-B exposure test were applied. In Table 3, the standardized methods and equipment settings are summarized for both accelerated weathering tests.

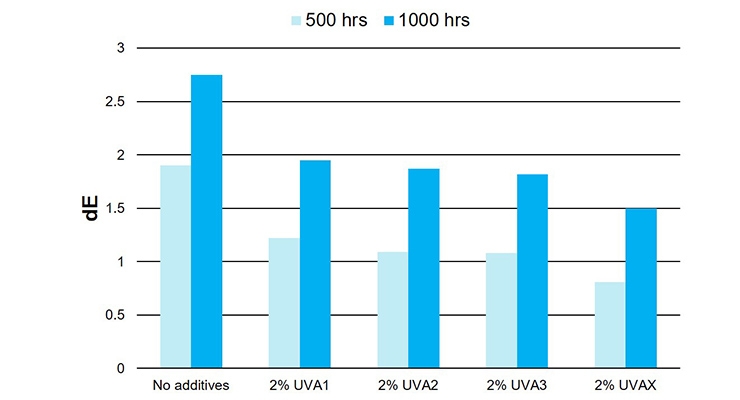

At the time this article was written, only 1000 hours exposure data were available. No significant differences in gloss among the tested products were observed for both accelerated weathering tests with such a short interval. With regard to color change (∆E), also no big difference was noticed with Weather-Ometer (WoM) exposure among the tested products; however, a clear trend could be observed in QUV-B at this interval, as shown in Graph 2.

Lower In-Can Color and Improved Durability

In a long-term study, Clariant aimed to develop a high-performing UV absorber solution for automotive refinish clearcoats. Selected criteria for high performance compared to currently used UV absorbers were lower in-can color and improved weathering performance. Based on the results shown primarily in Graphs 1 and 2, we demonstrated that with our newly developed UV absorber solution, a lower in-can color can be achieved along with improved durability. Accelerated weathering tests in WoM and QUV-B are still running up to 3000 hours to validate the results already compiled and illustrated in Graph 2.

Modification of Surface Appearance

Besides the long-lasting appearance of topcoats, smooth and scratch resistant automotive interiors are crucial for a pleasant driving-experience. For the modification of surfaces, additives are widely used in the coatings industry.

Mainly synthetic waxes play an important role for different kind of variations. Especially micronized waxes or polymers are able to provide a pleasant hand feeling. Clariant’s solutions, called Ceridust®, are very finely-micronized powder waxes, available in a particle size range between five to thirty micrometers. The additives are based on PE or oxidized PE wax, PP wax, Amide wax, FT wax, Montan wax, PTFE or Specialty waxes including renewable sources.

Creating the Feature Needed

Our wax portfolio can fulfill a car manufacturer’s requirements such as a glossy or matt appearance of interior car surfaces. With Ceridust 2740 TP the properties of liquid coatings can be influenced in such a way to meet those demands, while enabling a transparent protection of the coating. Also, smoothness and a pleasant haptic feel are key topics for automotive interiors, and here Ceridust 2740 TP contributes with the very narrow particle size distribution for an even and smooth finish. Last but not least, with the addition of this additive the robustness of the coating is influenced by increased scratch-resistance and higher chemical resistance. Ceridust 2740 TP can also be used in powder coatings, where it shows excellent degassing behavior and acts as a processing aid. The loosened and free-flowing nature of the powder allows easy incorporation in liquid or 100% UV systems.

Beyond that, it shows an anti-blocking effect for fast production cycles or easy storage handling.

Modified Natural Waxes Can Outperform Standard Waxes

Besides the conventional and commercially available standard wax compositions, the recent development of renewable additives opens a new field for automotive refinish coatings. Clariant has different approaches concerning sustainability. On the one hand, the specialty chemicals company has launched engineered waxes based on crude rice bran wax. And on the other hand, polymers based on saccharides with different molecular weight and particle sizes have been developed. These sustainable additives provide multiple new performance benefits. Ceridust 1060 TP is fully based on chemically upgraded rice bran wax, which is a non-food competing by-product of the rice oil production. The properties of this highly-functionalized micronized wax make it predestined for use in water-based systems. Therefore, it helps to reduce VOC emissions in automotive interiors. Next to very effective matting, slip modification and increased scratch-resistance, Ceridust 1060 TP generates an excellent

smooth finish.

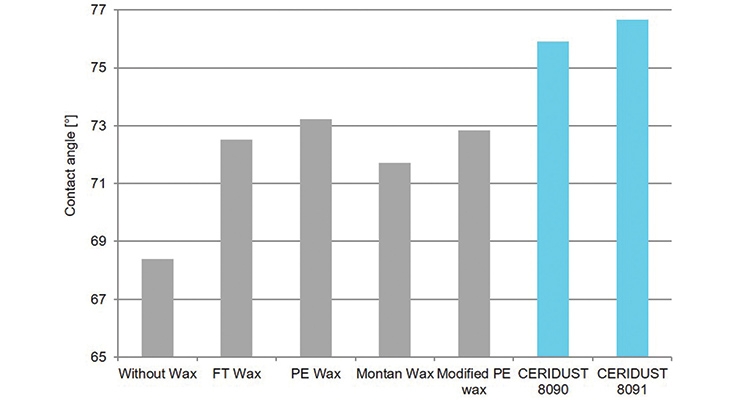

The majority of automotive interior plastic parts are made of PP. But wooden parts are sometimes used to complement dashboards with a natural element. In order to achieve a uniformly fine structured surface with a pleasant touch like natural wood, Ceridust 8090 can be used. The finer grade Ceridust 8091 creates even a warmer and smoother surface. The additives for highly durable water-based industrial coatings, based on polysaccharide, can outperform conventional wax additives in terms of their scratch-resistance performance. Furthermore, they provide an effective protection against unintended polishing and thus support keeping a matt finish. In some systems, like illustrated in Graph 3, the renewable Ceridust solutions show a better water repellent effect than standard waxes.

Outdoor durability of OEM and refinish topcoats has always been an important focus area throughout the automotive coating industry. The topcoat weathering requirements must meet more and more stringent market standards as coatings technology is evolving as well. However, automotive refinish topcoats have additional challenges, not relevant for the OEM topcoats due to the application processes.

Surely, there is no high-temperature bake for automotive refinish contrary to OEM coatings which restricts the resin technology enormously. Other challenges are found in the form of dust pick up, silicone contamination of the paint booth that would cause fish-eyes in the coating, irregularities in coating thickness due to multiple layer application, and finally the concept of improved in-can color.

UV Filter Properties and In-Can Color

The in-can color of an automotive refinish topcoat can be defined as the color of the clearcoat observed through the can by the paint applicator. This property is well known in the automotive refinish industry and is a challenge in all regions of the world. Applicators will always prefer a low in-can color clearcoat and will very often consider this as a key criteria to select their clearcoat suppliers.

The impact of in-can color on the weathering performance of an automotive topcoat is not intuitive. After all, the main factor influencing the in-can color is the UV absorber component of the topcoat. Indeed, the resins, which are by far the most important components of the topcoat have practically no impact on in-can color contrary to the UV absorber.

In a long-term study Clariant's coatings expert aimed to develop a unique UV absorber solution for automotive refinish clearcoats, enabling an improvement in weathering performance while keeping the paint in-can color at lowest level compared to current market standard.

Currently there are three types of UV absorbers used in automotive clearcoats, with each one having its own advantages and disadvantages , (Table 1 and Figure 1).

To understand the yellowing impact from each individual UV absorber on the in-can color properties in the formulation, Figure 2 represents the different absorbance curves for each UV absorber.

Referring to Figure 2, in theory oxalanilide UVAs should have the lowest initial color due to their UV absorbance being furthest away from the visible light spectrum (below 375 nm) when compared to other UV Absorbers.

However, referring back to Figure 1, it is clear from UVA4 (triazine) that the rationale of this theory is not supported at all times.

Table 2 refers to C* values, adding additional support to this rationale.

In the study, Clariant developed UVAX, an innovative UV absorber solution that exhibits the best in-can color properties, as is shown in C* measurements in Graph 1.

Weathering Tests

The next step of the study was to determine the weathering performance of the standard UV absorbers in a 2K-PU automotive clearcoat applied over a white basecoat and compare them to the newly developed (not yet commercialized) product UVAX. For the accelerated weathering tests, a xenon-arc artificial weathering instrument and the QUV-B exposure test were applied. In Table 3, the standardized methods and equipment settings are summarized for both accelerated weathering tests.

At the time this article was written, only 1000 hours exposure data were available. No significant differences in gloss among the tested products were observed for both accelerated weathering tests with such a short interval. With regard to color change (∆E), also no big difference was noticed with Weather-Ometer (WoM) exposure among the tested products; however, a clear trend could be observed in QUV-B at this interval, as shown in Graph 2.

Lower In-Can Color and Improved Durability

In a long-term study, Clariant aimed to develop a high-performing UV absorber solution for automotive refinish clearcoats. Selected criteria for high performance compared to currently used UV absorbers were lower in-can color and improved weathering performance. Based on the results shown primarily in Graphs 1 and 2, we demonstrated that with our newly developed UV absorber solution, a lower in-can color can be achieved along with improved durability. Accelerated weathering tests in WoM and QUV-B are still running up to 3000 hours to validate the results already compiled and illustrated in Graph 2.

Modification of Surface Appearance

Besides the long-lasting appearance of topcoats, smooth and scratch resistant automotive interiors are crucial for a pleasant driving-experience. For the modification of surfaces, additives are widely used in the coatings industry.

Mainly synthetic waxes play an important role for different kind of variations. Especially micronized waxes or polymers are able to provide a pleasant hand feeling. Clariant’s solutions, called Ceridust®, are very finely-micronized powder waxes, available in a particle size range between five to thirty micrometers. The additives are based on PE or oxidized PE wax, PP wax, Amide wax, FT wax, Montan wax, PTFE or Specialty waxes including renewable sources.

Creating the Feature Needed

Our wax portfolio can fulfill a car manufacturer’s requirements such as a glossy or matt appearance of interior car surfaces. With Ceridust 2740 TP the properties of liquid coatings can be influenced in such a way to meet those demands, while enabling a transparent protection of the coating. Also, smoothness and a pleasant haptic feel are key topics for automotive interiors, and here Ceridust 2740 TP contributes with the very narrow particle size distribution for an even and smooth finish. Last but not least, with the addition of this additive the robustness of the coating is influenced by increased scratch-resistance and higher chemical resistance. Ceridust 2740 TP can also be used in powder coatings, where it shows excellent degassing behavior and acts as a processing aid. The loosened and free-flowing nature of the powder allows easy incorporation in liquid or 100% UV systems.

Beyond that, it shows an anti-blocking effect for fast production cycles or easy storage handling.

Modified Natural Waxes Can Outperform Standard Waxes

Besides the conventional and commercially available standard wax compositions, the recent development of renewable additives opens a new field for automotive refinish coatings. Clariant has different approaches concerning sustainability. On the one hand, the specialty chemicals company has launched engineered waxes based on crude rice bran wax. And on the other hand, polymers based on saccharides with different molecular weight and particle sizes have been developed. These sustainable additives provide multiple new performance benefits. Ceridust 1060 TP is fully based on chemically upgraded rice bran wax, which is a non-food competing by-product of the rice oil production. The properties of this highly-functionalized micronized wax make it predestined for use in water-based systems. Therefore, it helps to reduce VOC emissions in automotive interiors. Next to very effective matting, slip modification and increased scratch-resistance, Ceridust 1060 TP generates an excellent

smooth finish.

The majority of automotive interior plastic parts are made of PP. But wooden parts are sometimes used to complement dashboards with a natural element. In order to achieve a uniformly fine structured surface with a pleasant touch like natural wood, Ceridust 8090 can be used. The finer grade Ceridust 8091 creates even a warmer and smoother surface. The additives for highly durable water-based industrial coatings, based on polysaccharide, can outperform conventional wax additives in terms of their scratch-resistance performance. Furthermore, they provide an effective protection against unintended polishing and thus support keeping a matt finish. In some systems, like illustrated in Graph 3, the renewable Ceridust solutions show a better water repellent effect than standard waxes.