Cecilia McGough, Thomas Sames and Heidi Carr, LANXESS Corporation, Pittsburgh, PA,USA 09.30.19

Abstract

How do you effectively preserve an exterior paint film to last? What are the chemical properties needed for the fungicides to control and inhibit fungal growth? In today’s coatings market, consumers are looking for an exterior paint that lasts years without biodeterioration. This is very challenging, as exterior paint films are exposed to outdoor environmental conditions containing high levels of microorganisms and nutrients for the microorganisms. Considering this, an exterior dry-film preservation system for coatings needs to have the following characteristics for microbiological protection: broad spectrum fungicide efficacy, good initial and long-term protection, and chemical stability in the wet and dry film stages. In addition, the dry-film fungicide must not adversely affect the finished paint film in terms of color change or increase the drying time. One powerful and widely used fungicide for dry-film protection is iodopropynylbutylcarbamate (IPBC) with efficacy against blue stain strains and mold growth on paint surfaces. Yet, IPBC has disadvantages like possible yellowing in the dried paint film and a medium-to-high leaching potential which may lead to shorter dried paint film life spans.

To overcome these disadvantages, combining individual fungicide actives usually provides a better toxicity profile, lower dosages, longer finished product shelf life, and compensates for weaknesses or gaps of individual fungicide actives. In several matrixes, propiconazole has been identified as a perfect active partner for IPBC. The combination was tested in different binders, on multiple substrates, and in multiple locations worldwide. In this paper, we look at the benefits of the combination of IPBC and propiconazole and other active ingredients in both laboratory and exterior weathering studies.

Background

A typical exterior paint consists of pigments, binder, solvent (e.g. water) and several different specialty additives to enhance the paint’s properties. Biocides are incorporated into the paint as one of the specialty additives. Biocides are separated into two different categories: in-can and dry-film preservatives. In-can preservatives are biocides that are added to the paint formulation to protect the paint from bacterial and fungal growth when in the wet state. Dry-film preservatives are biocides added to inhibit or control the fungal growth for interior paint systems and fungal and algal growth for exterior paint systems.1 Dry paint films undergo attack from fungi and algae microorganisms.2

The breakdown of an exterior paint film is caused by: high levels of nutrients in the environment and specialty raw materials, high levels of moisture on the film surface (e.g. condensation, rainfall) and poor maintenance of the film. The change in the moisture content can be from high levels of chemical leaching, and UV exposure.

Formulators have a very challenging task choosing the right dry-film preservative package. This is due to the need to have the following characteristics to provide microbiological protection: broad spectrum fungicidal efficacy, good initial and long-term protection, and chemical stability in both the wet stage and dry-film stages. In addition, the dry-film preservative must not adversely affect properties of the finished paint film (e.g. color, consistency of film, moisture content). In order to extend the efficacy and lifetime of a dried exterior paint film, it is beneficial to have a combination fungicide and algaecide.

Chemical Biocide Classes for Dry-Film Preservation

In addition to a broad efficacy spectrum, other important properties of a dry-film fungicide are low water solubility, low leaching, good wet stage stability, low volatility, and even distribution of the preservative throughout the dried film. No single dry-film preservative active has all of these characteristics. In fact, field studies have shown there to be some benefits to combining a fast-acting preservative with a long-term protection preservative to help extend the paint film life.

Dry-film preservatives are classified based on their chemical group. In this section, the dry-film preservatives will be summarized.

A) Isothiazolinones are a chemical class of preservatives that are electrophilic active agents with a heterocyclic N, S compound. The nitrogen-sulfur bonds target the amino, amide and thiol groups within the cell of the microorganisms.3

a. 4,5-dichloro-2-octyl-4-isothiazolin-3-one (DCOIT) is a broad spectrum fungicide with some efficacy against algae. DCOIT is fairly stable in the wet or in-can stage of the paint. DCOIT has good leaching and evaporation resistance due to its low water solubility (0.014 g/l at 25 °C). DCOIT is affected by oxidizing and reducing agents as well as primary and secondary amines. DCOIT has good temperature stability (>228 °C) and is effective over a pH range of 4-9. DCOIT has been recognized as a strong sensitizer in the European Union.4

b. 2-n-octyl-4-isothiazolin-3-one (OIT) is a broad spectrum fungicide. OIT has fair to good stability in the wet or in-can stage of the paint. OIT has low to medium leaching and evaporation resistance due to its moderate water solubility (0.48 g/l at 25 °C). OIT has fair to good temperature stability (≤100 °C)5 and is effective over a 2-10 pH range. Like most of the chemicals under the isothiazolinone class, OIT efficacy is affected by oxidizing and reducing agents as well as primary and secondary amines. OIT also has some gaps in fungicidal efficacy against Aspergillus sp. and Alternaria sp.6 OIT is also recognized as a strong sensitizer in the European Union.7,8

B) Pyrithione-based biocides are a chemical class of preservatives with a pyrithione structure that has antimicrobial and chelating properties.

a) Zinc pyrithione (ZPT), in addition to having fair-to-moderate efficacy against fungal organisms, also has slight algicidal efficacy. In the wet or in-can stage of the paint, ZPT is fairly stable. ZPT has good leaching and evaporation resistance due to its low water solubility (0.008 g/l at 25 °C). ZPT has a good temperature stability (<200 °C) and is effective over a pH range of 4-8.5. The chelating properties of ZPT may cause a discoloration of the paint formulation in the presence of metal ions. In addition, ZPT is not compatible with oxidizing/reducing agents or other chelating agents (e.g. EDTA). The main advantage of ZPT is that it is nonvolatile and will remain in the dried paint film.9,10

C) Activated Halogen biocides are electrophilic compounds having an activated halogen molecule in a meta position so it can react with the microbial cell. The difference in the electrical charge of the biocide and the microbial cell causes the cell membrane to rupture.11

a. Chlorothalonil (CTL) has fair efficacy with fungicidal gaps against Aspergillus niger and Penicillium sp. Stability of CTL in the wet or in-can stage of the paint is moderate to good. CTL has both excellent leaching resistance and excellent evaporation resistance due to the low water solubility (0.0006 g/l, 1 pm at 20 °C). In paint formulations, CTL is temperature stable >100 °C and in acid as well as in neutral pH, CTL is stable. However, pH above 9 may be prone to hydrolysis especially at higher temperatures. CTL is not supported for material protection use under the European Biocidal Products Regulation (BPR).12

D) Benzimidazoles are chemicals having an imidazole ring containing both acidic and basic nitrogen atoms.13

a. Thiabendazole (TBZ) has fair efficacy with fungicidal gaps against Alternaria sp. and Trichoderma sp. TBZ is stable in the wet and in-can stage of the paint. TBZ has low to fair leaching and evaporation resistance due to mobility of the molecule in the paint film. TBZ has low water solubility (0.03 g/l, 30 ppm). TBZ is temperature stable up to 300 °C and is effective across a broad pH range of 4-12. The main advantage of TBZ is the excellent toxicity profile of

this fungicide.14,15

b. Carbendazim (BCM) does have some fungicidal gaps against Alternaria sp. and Candida sp. The stability of BCM in the wet or in-can stage is moderate to good. BCM has both excellent leaching resistance and excellent evaporation resistance due to its low water solubility (0.008 g/l at 24 °C). Incorporation of BCM into a paint formulation is fair to good. BCM is temperature stable up to 180 °C and effective over a broad pH range of 2-12.16,17

E) Carbamates are a chemical class of preservatives that comprises the esters and salts of carbamic acids. Carbamates are highly effective fungicides that are quick acting and readily breakdown.

a. 3-Iodopropynylbutylcarbamate (IPBC) has excellent efficacy against most fungal organisms. It is the number one fungicide used in the market place for dry-film protection in the coatings market. IPBC has rather low stability in the wet stage of the paint. IPBC has low leaching resistance and low evaporation resistance due to its water solubility (0.168 g/l at 20 °C). IPBC may cause discoloration (e.g. yellowing) due to the iodine content. IPBC is easily incorporated into formulations and is available in an aqueous dispersion and a solvent-based solution. IPBC is stable at room temperature but prolonged temperatures above 80 °C can cause IPBC to breakdown. IPBC is also stable at acidic or neutral pH but will hydrolyze in alkaline conditions.18,19

F) Azoles are a chemical class of preservatives with the following structure: substituted aromatic heterocycles (e.g. imidazole, triazole), an unsubstituted nitrogen molecule at the meta position, one nitrogen molecule with a side chain that includes a lipophilic group and a benzene ring. These groups of preservatives were developed for the agricultural market.

a. Propiconazole (PPZ) has fair efficacy against fungal microorganisms with a gap against Trichoderma viride. PPZ is stable in the wet or in-can stage of the paint. With a low water solubility (0.10 g/l at 20 °C), PPZ has both high leaching resistance and high evaporation resistance. PPZ is very temperature stable up to 300 °C and effective over a wide pH range of 1-14. Performance is enhanced when blended with another fungicide.20-22

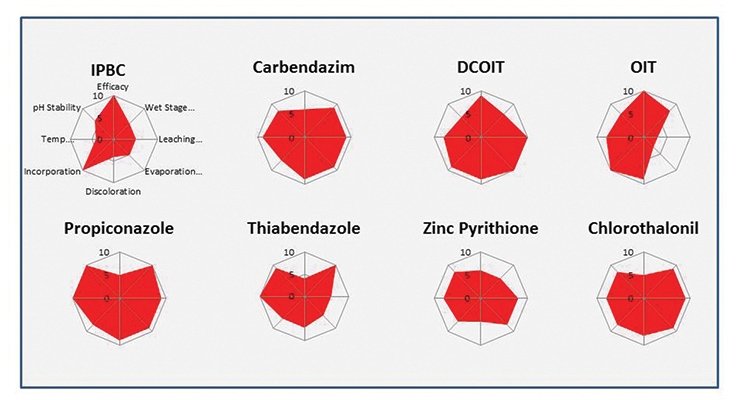

As illustrated in Figure 1, none of the individual actives have all of the desired characteristics. In combining the actives, the effectiveness of the dry-film preservation system will be improved.

Evaluation of the Effectiveness of Blended Fungicides for Dry-Film Protection

In order to successfully evaluate the dry-film preservation system, both laboratory and exterior weathering testing must be performed. The laboratory is used to screen the blended products in order to narrow the combination and ratios used. Exterior weathering studies are needed to obtain realistic data under environmental conditions.

Laboratory Fungi Testing

• ASTM G-2124 is a fungal resistance test method that was originally developed for plastics but is being used for other applications like coatings and gypsum. This method uses a five strain mixed inoculum to challenge a substrate to determine if it can resist the growth of mold on its surface. The samples are placed on Nutrient Salt agar and then the entire surface is sprayed with the mixed inoculum with a concentration of 1 x 106. Once inoculated, the samples are then incubated for four weeks at 30 °C. The samples are graded on a 0-4 scale and samples with no visual growth are inspected under a stereomicroscope to confirm lack of growth.

• ASTM D559025 is a fungal resistance test method that was specifically developed for coatings. Three strains are used to make two inoculums with a concentration of 1 x 104; one with two mold strains and the third strain by itself as its own inoculum. The samples are placed on a nutrient agar like Potato Dextrose or Malt agar with samples for both inoculum types separately. Once the surface is inoculated the samples are then incubated for four weeks at 30 °C. The samples are graded on a 0-4 scale.

Laboratory Algae Testing

• ASTM D558926 is an algal resistance test method that was specifically developed for coatings. Strains are selected from four different classes and are mixed equally to make a mixed algal inoculum. The samples are placed on media like Allen’s Medium or BG-11 agar and the inoculum sprayed onto the surface. Once inoculated the samples are then incubated with a light source for four weeks at 25 °C. The samples are graded on a 0-4 scale.

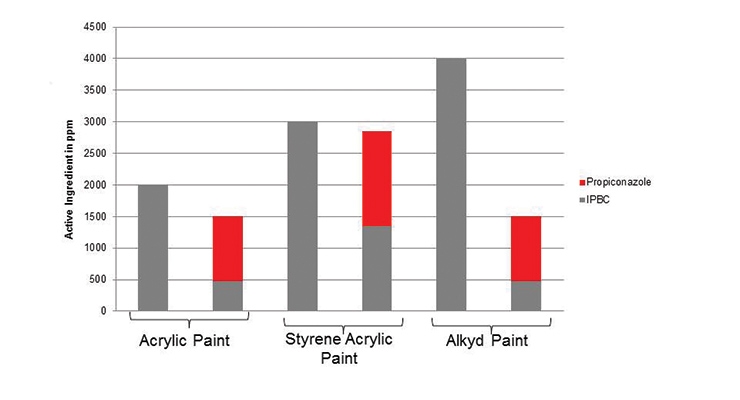

IPBC is a very powerful fungicide and it is often used as a single active ingredient in coatings. Even though IPBC alone works very well in ASTM G-21 lab testing, the combination of IPBC and PPZ reduced the total fungicide active concentration significantly in the tested systems (see Figure 2). Depending on the binder matrix and other raw materials in the paint formulation, the total fungicidal active concentration was reduced by up to 60%.

Outdoor Weathering Testing

Based on the findings from several laboratory studies, external weathering test panels were placed at outdoor weathering sites throughout the world (e.g. US, Europe, and Asia).

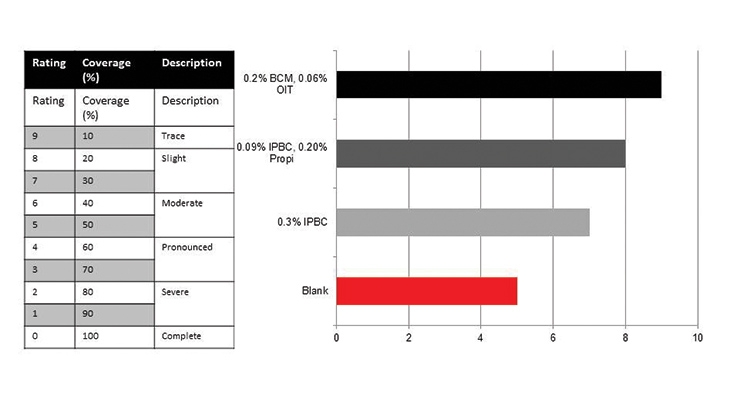

Besides PPZ/IPBC, a combination of BCM/OIT and IPBC alone are being evaluated in a water-based acrylic top coat.

After 24 months of exposure, it has been observed that IPBC alone is less effective than the combination products. This is probably due to higher leaching behavior and/or the UV degradation of IPBC.

As shown in Figure 3, the combination of BCM/OIT as well as the combination of PPZ/IPBC are effectively controlling fungal growth and are outperforming IPBC alone.

The combination of the 2:1 PPZ/IPBC has a low level of IPBC resulting in no noticeable yellowing of the dry paint film. Additionally, the combination PPZ/IPBC helps to extend the paint life through a higher leaching resistance due to PPZ.

Conclusion

Blending fungicides in order to overcome drawbacks of single active ingredients may contribute to decreased fungicidal content and/or provide a longer life time of the dried paint film.

The combination of BCM and OIT closes the BCM gap against Alternaria sp. and also provides short and long term efficacy because a high-leachable fungicide (OIT) is combined with a low-leachable fungicide (BCM).

This statement is also valid for the combination of PPZ and the widely used IPBC, as IPBC has strong fungicidal efficacy with medium-to-high leaching potential. By using the lower-leachable PPZ, in combination with IPBC, a long lasting fungal protection can be achieved.

Both BCM/OIT and PPZ/IPBC blends are highly effective combinations providing long-term fungal protection for the dried paint film.

Finally, the decision about which active ingredient combination is the best fit, depends on possible regulatory requirements, paint properties, raw materials and preservation costs.

References

1 www.paintquality.com,”The Ingredients of Paint and Their Impact on Paint Properties”, The Paint Quality Institute, 2000

2 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG

3 Ibid p.44

4 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook, p. 663

5 Ibid p.662

6 Vincentz Network, European Coatings Journal, “Playing it Safe”, Sauer, Dr. Frank, 07-08/2007 p. 34

7 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.65

8 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.662

9 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.64-65

10 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.644

11 Ibid p.704

12 https://echa.europa.eu/de/home

13 http://cdn.intechopen.com/pdfs/12392/InTechBenzimidazole_fungicides_in_environmental_samples_extraction_and_determination_procedures.pdf

14 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.669-670

15 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.70

16 Ibid p.71

17 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.622-623

18 Ibid p.619

19 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.70

20 Synegenta Website-Products and Innovation/Product-Brands/Celest®

21 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.653

22 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.69

23 Sames, Thomas: PSCT Presentation April 15, 2019 Preservation of Paints & Coatings In-Can and Dry-Film Preservation of Paints & Coatings.Slide no. 14

24 ASTM Standard D5590-17, “Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi” ASTM International, West Conshohochen, PA, 2015, DOI:10.1520/G0021-15

25 ASTM Standard G21-15, “Standard Practice for Determining the Resistance of Paint Films and Related Coatings to Fungal Defacement by Accelerated Four-Week Agar Plate Assay” ASTM International, West Conshohochen, PA, 2015, DOI:10.1520/D5590-17

26 ASTM Standard D5589-09 (Reapproved 2013), “Standard Practice for Determining the Resistance of Paint Films and Related Coatings to Algal Defacement” ASTM International, West Conshohochen, PA, 2015, DOI:10.1520/D5589-09R13

27 Sames, Thomas: PSCT Presentation April 15, 2019 Preservation of Paints & Coatings In-Can and Dry-Film Preservation of Paints & Coatings.Slide no. 18

28 Sames, Thomas: PSCT Presentation April 15, 2019 Preservation of Paints & Coatings In-Can and Dry-Film Preservation of Paints & Coatings.Slide no. 20

How do you effectively preserve an exterior paint film to last? What are the chemical properties needed for the fungicides to control and inhibit fungal growth? In today’s coatings market, consumers are looking for an exterior paint that lasts years without biodeterioration. This is very challenging, as exterior paint films are exposed to outdoor environmental conditions containing high levels of microorganisms and nutrients for the microorganisms. Considering this, an exterior dry-film preservation system for coatings needs to have the following characteristics for microbiological protection: broad spectrum fungicide efficacy, good initial and long-term protection, and chemical stability in the wet and dry film stages. In addition, the dry-film fungicide must not adversely affect the finished paint film in terms of color change or increase the drying time. One powerful and widely used fungicide for dry-film protection is iodopropynylbutylcarbamate (IPBC) with efficacy against blue stain strains and mold growth on paint surfaces. Yet, IPBC has disadvantages like possible yellowing in the dried paint film and a medium-to-high leaching potential which may lead to shorter dried paint film life spans.

To overcome these disadvantages, combining individual fungicide actives usually provides a better toxicity profile, lower dosages, longer finished product shelf life, and compensates for weaknesses or gaps of individual fungicide actives. In several matrixes, propiconazole has been identified as a perfect active partner for IPBC. The combination was tested in different binders, on multiple substrates, and in multiple locations worldwide. In this paper, we look at the benefits of the combination of IPBC and propiconazole and other active ingredients in both laboratory and exterior weathering studies.

Background

A typical exterior paint consists of pigments, binder, solvent (e.g. water) and several different specialty additives to enhance the paint’s properties. Biocides are incorporated into the paint as one of the specialty additives. Biocides are separated into two different categories: in-can and dry-film preservatives. In-can preservatives are biocides that are added to the paint formulation to protect the paint from bacterial and fungal growth when in the wet state. Dry-film preservatives are biocides added to inhibit or control the fungal growth for interior paint systems and fungal and algal growth for exterior paint systems.1 Dry paint films undergo attack from fungi and algae microorganisms.2

The breakdown of an exterior paint film is caused by: high levels of nutrients in the environment and specialty raw materials, high levels of moisture on the film surface (e.g. condensation, rainfall) and poor maintenance of the film. The change in the moisture content can be from high levels of chemical leaching, and UV exposure.

Formulators have a very challenging task choosing the right dry-film preservative package. This is due to the need to have the following characteristics to provide microbiological protection: broad spectrum fungicidal efficacy, good initial and long-term protection, and chemical stability in both the wet stage and dry-film stages. In addition, the dry-film preservative must not adversely affect properties of the finished paint film (e.g. color, consistency of film, moisture content). In order to extend the efficacy and lifetime of a dried exterior paint film, it is beneficial to have a combination fungicide and algaecide.

Chemical Biocide Classes for Dry-Film Preservation

In addition to a broad efficacy spectrum, other important properties of a dry-film fungicide are low water solubility, low leaching, good wet stage stability, low volatility, and even distribution of the preservative throughout the dried film. No single dry-film preservative active has all of these characteristics. In fact, field studies have shown there to be some benefits to combining a fast-acting preservative with a long-term protection preservative to help extend the paint film life.

Dry-film preservatives are classified based on their chemical group. In this section, the dry-film preservatives will be summarized.

A) Isothiazolinones are a chemical class of preservatives that are electrophilic active agents with a heterocyclic N, S compound. The nitrogen-sulfur bonds target the amino, amide and thiol groups within the cell of the microorganisms.3

a. 4,5-dichloro-2-octyl-4-isothiazolin-3-one (DCOIT) is a broad spectrum fungicide with some efficacy against algae. DCOIT is fairly stable in the wet or in-can stage of the paint. DCOIT has good leaching and evaporation resistance due to its low water solubility (0.014 g/l at 25 °C). DCOIT is affected by oxidizing and reducing agents as well as primary and secondary amines. DCOIT has good temperature stability (>228 °C) and is effective over a pH range of 4-9. DCOIT has been recognized as a strong sensitizer in the European Union.4

b. 2-n-octyl-4-isothiazolin-3-one (OIT) is a broad spectrum fungicide. OIT has fair to good stability in the wet or in-can stage of the paint. OIT has low to medium leaching and evaporation resistance due to its moderate water solubility (0.48 g/l at 25 °C). OIT has fair to good temperature stability (≤100 °C)5 and is effective over a 2-10 pH range. Like most of the chemicals under the isothiazolinone class, OIT efficacy is affected by oxidizing and reducing agents as well as primary and secondary amines. OIT also has some gaps in fungicidal efficacy against Aspergillus sp. and Alternaria sp.6 OIT is also recognized as a strong sensitizer in the European Union.7,8

B) Pyrithione-based biocides are a chemical class of preservatives with a pyrithione structure that has antimicrobial and chelating properties.

a) Zinc pyrithione (ZPT), in addition to having fair-to-moderate efficacy against fungal organisms, also has slight algicidal efficacy. In the wet or in-can stage of the paint, ZPT is fairly stable. ZPT has good leaching and evaporation resistance due to its low water solubility (0.008 g/l at 25 °C). ZPT has a good temperature stability (<200 °C) and is effective over a pH range of 4-8.5. The chelating properties of ZPT may cause a discoloration of the paint formulation in the presence of metal ions. In addition, ZPT is not compatible with oxidizing/reducing agents or other chelating agents (e.g. EDTA). The main advantage of ZPT is that it is nonvolatile and will remain in the dried paint film.9,10

C) Activated Halogen biocides are electrophilic compounds having an activated halogen molecule in a meta position so it can react with the microbial cell. The difference in the electrical charge of the biocide and the microbial cell causes the cell membrane to rupture.11

a. Chlorothalonil (CTL) has fair efficacy with fungicidal gaps against Aspergillus niger and Penicillium sp. Stability of CTL in the wet or in-can stage of the paint is moderate to good. CTL has both excellent leaching resistance and excellent evaporation resistance due to the low water solubility (0.0006 g/l, 1 pm at 20 °C). In paint formulations, CTL is temperature stable >100 °C and in acid as well as in neutral pH, CTL is stable. However, pH above 9 may be prone to hydrolysis especially at higher temperatures. CTL is not supported for material protection use under the European Biocidal Products Regulation (BPR).12

D) Benzimidazoles are chemicals having an imidazole ring containing both acidic and basic nitrogen atoms.13

a. Thiabendazole (TBZ) has fair efficacy with fungicidal gaps against Alternaria sp. and Trichoderma sp. TBZ is stable in the wet and in-can stage of the paint. TBZ has low to fair leaching and evaporation resistance due to mobility of the molecule in the paint film. TBZ has low water solubility (0.03 g/l, 30 ppm). TBZ is temperature stable up to 300 °C and is effective across a broad pH range of 4-12. The main advantage of TBZ is the excellent toxicity profile of

this fungicide.14,15

b. Carbendazim (BCM) does have some fungicidal gaps against Alternaria sp. and Candida sp. The stability of BCM in the wet or in-can stage is moderate to good. BCM has both excellent leaching resistance and excellent evaporation resistance due to its low water solubility (0.008 g/l at 24 °C). Incorporation of BCM into a paint formulation is fair to good. BCM is temperature stable up to 180 °C and effective over a broad pH range of 2-12.16,17

E) Carbamates are a chemical class of preservatives that comprises the esters and salts of carbamic acids. Carbamates are highly effective fungicides that are quick acting and readily breakdown.

a. 3-Iodopropynylbutylcarbamate (IPBC) has excellent efficacy against most fungal organisms. It is the number one fungicide used in the market place for dry-film protection in the coatings market. IPBC has rather low stability in the wet stage of the paint. IPBC has low leaching resistance and low evaporation resistance due to its water solubility (0.168 g/l at 20 °C). IPBC may cause discoloration (e.g. yellowing) due to the iodine content. IPBC is easily incorporated into formulations and is available in an aqueous dispersion and a solvent-based solution. IPBC is stable at room temperature but prolonged temperatures above 80 °C can cause IPBC to breakdown. IPBC is also stable at acidic or neutral pH but will hydrolyze in alkaline conditions.18,19

F) Azoles are a chemical class of preservatives with the following structure: substituted aromatic heterocycles (e.g. imidazole, triazole), an unsubstituted nitrogen molecule at the meta position, one nitrogen molecule with a side chain that includes a lipophilic group and a benzene ring. These groups of preservatives were developed for the agricultural market.

a. Propiconazole (PPZ) has fair efficacy against fungal microorganisms with a gap against Trichoderma viride. PPZ is stable in the wet or in-can stage of the paint. With a low water solubility (0.10 g/l at 20 °C), PPZ has both high leaching resistance and high evaporation resistance. PPZ is very temperature stable up to 300 °C and effective over a wide pH range of 1-14. Performance is enhanced when blended with another fungicide.20-22

As illustrated in Figure 1, none of the individual actives have all of the desired characteristics. In combining the actives, the effectiveness of the dry-film preservation system will be improved.

Evaluation of the Effectiveness of Blended Fungicides for Dry-Film Protection

In order to successfully evaluate the dry-film preservation system, both laboratory and exterior weathering testing must be performed. The laboratory is used to screen the blended products in order to narrow the combination and ratios used. Exterior weathering studies are needed to obtain realistic data under environmental conditions.

Laboratory Fungi Testing

• ASTM G-2124 is a fungal resistance test method that was originally developed for plastics but is being used for other applications like coatings and gypsum. This method uses a five strain mixed inoculum to challenge a substrate to determine if it can resist the growth of mold on its surface. The samples are placed on Nutrient Salt agar and then the entire surface is sprayed with the mixed inoculum with a concentration of 1 x 106. Once inoculated, the samples are then incubated for four weeks at 30 °C. The samples are graded on a 0-4 scale and samples with no visual growth are inspected under a stereomicroscope to confirm lack of growth.

• ASTM D559025 is a fungal resistance test method that was specifically developed for coatings. Three strains are used to make two inoculums with a concentration of 1 x 104; one with two mold strains and the third strain by itself as its own inoculum. The samples are placed on a nutrient agar like Potato Dextrose or Malt agar with samples for both inoculum types separately. Once the surface is inoculated the samples are then incubated for four weeks at 30 °C. The samples are graded on a 0-4 scale.

Laboratory Algae Testing

• ASTM D558926 is an algal resistance test method that was specifically developed for coatings. Strains are selected from four different classes and are mixed equally to make a mixed algal inoculum. The samples are placed on media like Allen’s Medium or BG-11 agar and the inoculum sprayed onto the surface. Once inoculated the samples are then incubated with a light source for four weeks at 25 °C. The samples are graded on a 0-4 scale.

IPBC is a very powerful fungicide and it is often used as a single active ingredient in coatings. Even though IPBC alone works very well in ASTM G-21 lab testing, the combination of IPBC and PPZ reduced the total fungicide active concentration significantly in the tested systems (see Figure 2). Depending on the binder matrix and other raw materials in the paint formulation, the total fungicidal active concentration was reduced by up to 60%.

Outdoor Weathering Testing

Based on the findings from several laboratory studies, external weathering test panels were placed at outdoor weathering sites throughout the world (e.g. US, Europe, and Asia).

Besides PPZ/IPBC, a combination of BCM/OIT and IPBC alone are being evaluated in a water-based acrylic top coat.

After 24 months of exposure, it has been observed that IPBC alone is less effective than the combination products. This is probably due to higher leaching behavior and/or the UV degradation of IPBC.

As shown in Figure 3, the combination of BCM/OIT as well as the combination of PPZ/IPBC are effectively controlling fungal growth and are outperforming IPBC alone.

The combination of the 2:1 PPZ/IPBC has a low level of IPBC resulting in no noticeable yellowing of the dry paint film. Additionally, the combination PPZ/IPBC helps to extend the paint life through a higher leaching resistance due to PPZ.

Conclusion

Blending fungicides in order to overcome drawbacks of single active ingredients may contribute to decreased fungicidal content and/or provide a longer life time of the dried paint film.

The combination of BCM and OIT closes the BCM gap against Alternaria sp. and also provides short and long term efficacy because a high-leachable fungicide (OIT) is combined with a low-leachable fungicide (BCM).

This statement is also valid for the combination of PPZ and the widely used IPBC, as IPBC has strong fungicidal efficacy with medium-to-high leaching potential. By using the lower-leachable PPZ, in combination with IPBC, a long lasting fungal protection can be achieved.

Both BCM/OIT and PPZ/IPBC blends are highly effective combinations providing long-term fungal protection for the dried paint film.

Finally, the decision about which active ingredient combination is the best fit, depends on possible regulatory requirements, paint properties, raw materials and preservation costs.

References

1 www.paintquality.com,”The Ingredients of Paint and Their Impact on Paint Properties”, The Paint Quality Institute, 2000

2 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG

3 Ibid p.44

4 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook, p. 663

5 Ibid p.662

6 Vincentz Network, European Coatings Journal, “Playing it Safe”, Sauer, Dr. Frank, 07-08/2007 p. 34

7 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.65

8 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.662

9 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.64-65

10 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.644

11 Ibid p.704

12 https://echa.europa.eu/de/home

13 http://cdn.intechopen.com/pdfs/12392/InTechBenzimidazole_fungicides_in_environmental_samples_extraction_and_determination_procedures.pdf

14 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.669-670

15 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.70

16 Ibid p.71

17 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.622-623

18 Ibid p.619

19 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.70

20 Synegenta Website-Products and Innovation/Product-Brands/Celest®

21 Edited by Wilfried Paulus, Directory of Microbicides for the Protection of Materials, A Handbook,p.653

22 Sauer, F. (2017). Microbicides in Coating. Hanover, Germany: Vincentz Gmbh & Co. KG. p.69

23 Sames, Thomas: PSCT Presentation April 15, 2019 Preservation of Paints & Coatings In-Can and Dry-Film Preservation of Paints & Coatings.Slide no. 14

24 ASTM Standard D5590-17, “Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi” ASTM International, West Conshohochen, PA, 2015, DOI:10.1520/G0021-15

25 ASTM Standard G21-15, “Standard Practice for Determining the Resistance of Paint Films and Related Coatings to Fungal Defacement by Accelerated Four-Week Agar Plate Assay” ASTM International, West Conshohochen, PA, 2015, DOI:10.1520/D5590-17

26 ASTM Standard D5589-09 (Reapproved 2013), “Standard Practice for Determining the Resistance of Paint Films and Related Coatings to Algal Defacement” ASTM International, West Conshohochen, PA, 2015, DOI:10.1520/D5589-09R13

27 Sames, Thomas: PSCT Presentation April 15, 2019 Preservation of Paints & Coatings In-Can and Dry-Film Preservation of Paints & Coatings.Slide no. 18

28 Sames, Thomas: PSCT Presentation April 15, 2019 Preservation of Paints & Coatings In-Can and Dry-Film Preservation of Paints & Coatings.Slide no. 20