02.19.20

American Machining, Inc.

Fenton, MI USA

877-629-0091

Fax: 810-629-0046

tiffany@ibcresouce.com

www.ibcresource.com

Poly-Ship & Mix

Attributes/Comments: The Poly-Ship & Mix is an innovate solution for companies who mix and ship products. This new patent pending mixer allows you to do both. It is engineered with an airtight Teflon seal that meets all DOT and safety requirements. It has a stainless steel shaft contained within a sealed cap with bearings for a smooth running application. Can be sold stand alone with a bridge attachment or as a full mounted mixing system.

A.W.T. World Trade, Inc.

Chicago, IL USA

773-777-7100

Fax: 773-777-0909

sales@awtworldtrade.com

www.awt-gpi.com

Tornado Ink Mixer Ink Mixer & Color Blender

Attributes/Comments: A.W.T.’s Tornado Ink Mixer & Color Blender is ideal for mixing matched colors, adding pigments such as glitter or fluorescent color to bases, and for assuring proper blending of reducers and other modifiers. The unique design of the Tornado saves time by mixing right in the original container.

Buhler Inc.

Mahwah, NJ USA

201-847-0600

gdnorthamerica@buhlergroup.com

www.buhlergroup.com/wetgrinding_dispersing

Visconomic+

Attributes/Comments: Visconomic+ allows high flow rates even with high viscous products. The unique process chamber design provides efficient wet grinding and dispersing. Visconomic+ has flexible control options and provides temperature control while the ceramic inner liner offers efficient cooling and improved wear performance.

Blade Depot (A division of Norstone, Inc.)

Bridgeport, PA USA

484-684-6986

Fax: 610-275-2404

sales@bladedepot.net

www.bladedepot.net

Polyblade DHS with diamond shaped teeth and pumping scoops

Attributes/Comments: Diamond shaped teeth. Easy cleaning. Lower amperage.

3, 6 or 9 scoops. 1-4 teeth between scoops.

Available in one sided for air entrainment reduction. Handles ALL viscosities. Never sharpens. Dual sided. Lasts far longer than steel blades even when used with media.

Charles Ross and Son Company

Hauppauge, NY USA

631-234-0500

Fax: 631-234-0691

mail@mixers.com

www.mixers.com

Double Planetary Mixing & Discharging in a Sanitary Turnkey System

Attributes/Comments: The ROSS Double Planetary Mixer is available in a “super sanitary” turnkey configuration, featuring a common stainless steel workbench for both the mixer and a matching discharge system. On the sanitary 4-gallon Double Planetary Mixer & Discharge System Model DPM/DS-4S shown, both interior and exterior stainless steel surfaces are type 316, with a 150-grit (#4) finish and electropolished. Its jacketed mixing vessel and special high viscosity blades are a dynamic combination for producing thick gels, pastes, putties and other semi-solids under precise temperatures. 100% sealed gearbox and stirrer shafts ensure complete cleanability and eliminate cross-contamination between batches. This system is scalable through 1,000-gallon production models.

ROSS Triple Shaft Mixer with Powder Induction Manifold

Attributes/Comments: The latest 600-gallon ROSS VersaMix Model VM-600 is capable of high speed subsurface powder induction with proprietary ROSS Solids/Liquid Injection Manifold (SLIM). SLIM incorporates powder or liquid phases directly into the rotor-stator mix head, causing instant wet out as it rotates at 3,600 RPM. The classic dual-post triple-shaft design has been revolutionized with this feature to streamline the processing of substantial powder phases. The robust anchor agitator moves product from the high shear rotor stator head to a high-speed dispersing head, which deagglomerates any remaining fish eyes. Used to quickly mix large batches throughout the process industries, the SLIM feature accelerates loading phases exponentially. This design is available from laboratory sizes upwards of 4,000 gallons.

Custom Milling

& Consulting, Inc.

Fleetwood, PA USA

610-926-0984

Fax: 610-926-0984

sales@cmcmilling.com

www.cmcmilling.com

Planetary Plus Mixer

Attributes/Comments: CMC’s line of Planetary Plus Mixers provide a powerful “combination” of mixing elements for the most demanding high viscosity, high shear, and temperature sensitive products. The mixer is constructed with a pair of planetary finger blades, high shear dispersing blade, and a side wall scraper. Each finger blade rotates on its own axis while simultaneously orbiting around the mixing vessel while the high shear blade is mounted in the center. The angled design of the finger blades pumps the materials up from the bottom and down from the top to insure complete turnover.

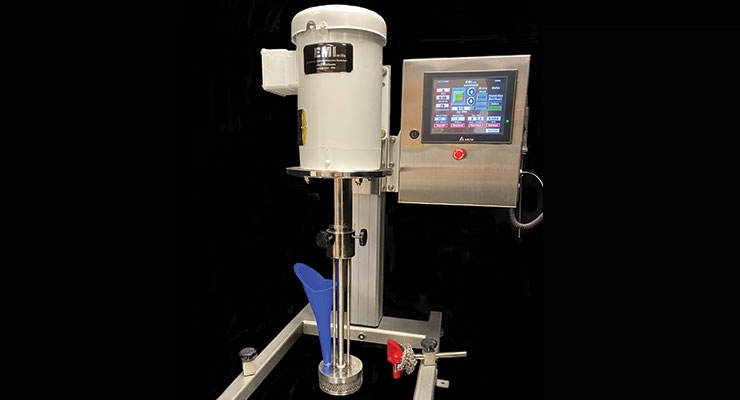

Engineered Mills, Inc.

Grayslake, IL USA

847-548-0044

Dave.Peterson@EMImills.com

www.EMImills.com

Mixer/Disperser with Powder Induction

Attributes/Comments: EMImills laboratory high speed mixers are available with a Rotor/Stator mixing head with powder induction system to allow efficient wetting of powders through sub level addition. The EMI Rotor/Stator head provides high shear forces while creating a vacuum that will draw material from the feed funnel and directly into the carrier fluid that is being pumped from the vessel bottom. Dusting from powder is reduced at the same time initial wetting occurs. The mixer is variable speed and available in different horsepower’s and mixer sizes. Contact EMImills regarding your process application.

Glen Mills Inc.

Clifton, NJ USA

973-777-0777

Fax: 973-7770070

info@glenmills.com

www.glenmills.com

Kakhunter Centrifugal Planetary Mixer

Attributes/Comments: Kakhunter Centrifugal Planetary Mixers is used for mixing/blending of viscous liquids and pastes. The intense 2,000+ rpm motion moving the container in both rotational (“daily”) and revolutionary (“yearly”) directions creates homogenous blends. Also, efficient for degassing and powder dispersion.

Hero Products Group

Vancouver, Canada

604-522-6543

Fax: 604-522-8735

sales@hero.ca

www.hero.ca

S2650 5-Gallon Shaker

Attributes/comments: S2650 is a quiet, sturdy and reliable 5-gallon shaker with a small footprint that combines vibrational technology with a clamping system that thoroughly mixes from a 1/2 pint to a

5 gallon container, including cases; increasing efficiency and versatility.

Hockmeyer Equipment Corporation

Elizabeth City, NC USA

800-906-7278

Fax: 252-338-4705

sales@hockmeyer.com

www.hockmeyer.com

HHL Mixer

Attributes/Comments: The Hockmeyer HHL Mixer series can be dual or triple shaft units available in XP or TEFC configurations. There are high speed and low speed options available, including the helical sweep with patented dual reversible scraper.

Myers Mixers

Cudahy, CA USA

332-560-4723

Fax: 323-771-7789

sales@myersmixers.com

www.myersmixers.com

600/500 Series Horizontal Tank-

Mounted Mixer

Attributes/Comments: Myers Mixers introduces a horizontal mixer for intermediate-speed blending and mixing of viscous coatings. Eight bolt-on style blades homogenize the batch with minimal shear, while close tolerance between impellers and tank sidewall ensure batch uniformity, and the dimple-jacketed, ASME-rated tank provides an even batch temperature. Bolted end allows for simplified maintenance and cleaning.

Netzsch Premier Technologies, LLC

Exton, PA USA

484-879-2020

info.npt@netzsch.com

www.netzsch.com/gd

Epsilon Inline Disperser

Attributes/Comments: NETZSCH offers a new, compact solution for producing homogeneous dispersions with reproducible quality in an inline process. The dispersion process takes place in an atmospherically sealed processing chamber, and is dust and emission free.

Psi-Mix

Attributes/Comments: An inline disperser for wetting solid components on a large liquid surface, with emission- free, dust-free inline operation. The combination of vacuum dispersion, shearing and pressure wetting results in homogeneous, fine dispersions with very reproducible quality.

Reynolds Industries Inc.

Fort Mill, SC USA

803-548-4501

Fax: 803-792-9231

k.reynolds@reynoldsmixers.com

www.reyonoldsmixers.com

ASME Certified Manufacturer

Attributes/Comments: Reynolds Industries has been manufacturing tanks and vessels for 46 years. We are now ASME Certified with U, U2 and R certifications, allowing Reynolds to provide code stamped vessels to customers.

Sunin Machine Co., Ltd.

New Taipei City, Taiwan

+866-2-22407863

Fax: +886-2-22402596

Sunin168@ms31.hinet.net

www.sunin-machine.com

Dispersion Mixer

Attributes/Comments: Dispersion mixer is a machine suitable for work in narrow spaces in laboratories, with a handy and practical design. The double-purpose mixing cup can be cooled and heated through a pipe connector according to different formulas. The innovative working structure can realize both mixing and dispersion, and reduce material loss and environmental pollution during the transfer by peripheral pump.

Union Process Inc.

Akron, OH USA

330-929-3333

unionprocess@unionprocess.com

www.unionprocess.com

PTO-1000 Mixer (Pre-mix table)

Attributes/Comments: The PT-1000 pre-mix table is attached to the Union Process QL-100 Attritor for recirculation milling/mixing. Can be used to pre-mix thorough dispersion for various mixing or milling applications.

WAB US Corp.

Allendale, NJ USA

wab-us@wab-group.com

www.wab-group.com

The DYNO-MILL UBM:

Universal Bead Mill

Attributes/Comments: Covering the entire range from dispersion to micro/nano grinding, these new high-yield mills are suitable for grinding bead diameters from 0.2 to 2.5 mm, and allow for processing of high-viscosity products at a significantly increased production capacity.

Fenton, MI USA

877-629-0091

Fax: 810-629-0046

tiffany@ibcresouce.com

www.ibcresource.com

Poly-Ship & Mix

Attributes/Comments: The Poly-Ship & Mix is an innovate solution for companies who mix and ship products. This new patent pending mixer allows you to do both. It is engineered with an airtight Teflon seal that meets all DOT and safety requirements. It has a stainless steel shaft contained within a sealed cap with bearings for a smooth running application. Can be sold stand alone with a bridge attachment or as a full mounted mixing system.

A.W.T. World Trade, Inc.

Chicago, IL USA

773-777-7100

Fax: 773-777-0909

sales@awtworldtrade.com

www.awt-gpi.com

Tornado Ink Mixer Ink Mixer & Color Blender

Attributes/Comments: A.W.T.’s Tornado Ink Mixer & Color Blender is ideal for mixing matched colors, adding pigments such as glitter or fluorescent color to bases, and for assuring proper blending of reducers and other modifiers. The unique design of the Tornado saves time by mixing right in the original container.

Buhler Inc.

Mahwah, NJ USA

201-847-0600

gdnorthamerica@buhlergroup.com

www.buhlergroup.com/wetgrinding_dispersing

Visconomic+

Attributes/Comments: Visconomic+ allows high flow rates even with high viscous products. The unique process chamber design provides efficient wet grinding and dispersing. Visconomic+ has flexible control options and provides temperature control while the ceramic inner liner offers efficient cooling and improved wear performance.

Blade Depot (A division of Norstone, Inc.)

Bridgeport, PA USA

484-684-6986

Fax: 610-275-2404

sales@bladedepot.net

www.bladedepot.net

Polyblade DHS with diamond shaped teeth and pumping scoops

Attributes/Comments: Diamond shaped teeth. Easy cleaning. Lower amperage.

3, 6 or 9 scoops. 1-4 teeth between scoops.

Available in one sided for air entrainment reduction. Handles ALL viscosities. Never sharpens. Dual sided. Lasts far longer than steel blades even when used with media.

Charles Ross and Son Company

Hauppauge, NY USA

631-234-0500

Fax: 631-234-0691

mail@mixers.com

www.mixers.com

Double Planetary Mixing & Discharging in a Sanitary Turnkey System

Attributes/Comments: The ROSS Double Planetary Mixer is available in a “super sanitary” turnkey configuration, featuring a common stainless steel workbench for both the mixer and a matching discharge system. On the sanitary 4-gallon Double Planetary Mixer & Discharge System Model DPM/DS-4S shown, both interior and exterior stainless steel surfaces are type 316, with a 150-grit (#4) finish and electropolished. Its jacketed mixing vessel and special high viscosity blades are a dynamic combination for producing thick gels, pastes, putties and other semi-solids under precise temperatures. 100% sealed gearbox and stirrer shafts ensure complete cleanability and eliminate cross-contamination between batches. This system is scalable through 1,000-gallon production models.

ROSS Triple Shaft Mixer with Powder Induction Manifold

Attributes/Comments: The latest 600-gallon ROSS VersaMix Model VM-600 is capable of high speed subsurface powder induction with proprietary ROSS Solids/Liquid Injection Manifold (SLIM). SLIM incorporates powder or liquid phases directly into the rotor-stator mix head, causing instant wet out as it rotates at 3,600 RPM. The classic dual-post triple-shaft design has been revolutionized with this feature to streamline the processing of substantial powder phases. The robust anchor agitator moves product from the high shear rotor stator head to a high-speed dispersing head, which deagglomerates any remaining fish eyes. Used to quickly mix large batches throughout the process industries, the SLIM feature accelerates loading phases exponentially. This design is available from laboratory sizes upwards of 4,000 gallons.

Custom Milling

& Consulting, Inc.

Fleetwood, PA USA

610-926-0984

Fax: 610-926-0984

sales@cmcmilling.com

www.cmcmilling.com

Planetary Plus Mixer

Attributes/Comments: CMC’s line of Planetary Plus Mixers provide a powerful “combination” of mixing elements for the most demanding high viscosity, high shear, and temperature sensitive products. The mixer is constructed with a pair of planetary finger blades, high shear dispersing blade, and a side wall scraper. Each finger blade rotates on its own axis while simultaneously orbiting around the mixing vessel while the high shear blade is mounted in the center. The angled design of the finger blades pumps the materials up from the bottom and down from the top to insure complete turnover.

Engineered Mills, Inc.

Grayslake, IL USA

847-548-0044

Dave.Peterson@EMImills.com

www.EMImills.com

Mixer/Disperser with Powder Induction

Attributes/Comments: EMImills laboratory high speed mixers are available with a Rotor/Stator mixing head with powder induction system to allow efficient wetting of powders through sub level addition. The EMI Rotor/Stator head provides high shear forces while creating a vacuum that will draw material from the feed funnel and directly into the carrier fluid that is being pumped from the vessel bottom. Dusting from powder is reduced at the same time initial wetting occurs. The mixer is variable speed and available in different horsepower’s and mixer sizes. Contact EMImills regarding your process application.

Glen Mills Inc.

Clifton, NJ USA

973-777-0777

Fax: 973-7770070

info@glenmills.com

www.glenmills.com

Kakhunter Centrifugal Planetary Mixer

Attributes/Comments: Kakhunter Centrifugal Planetary Mixers is used for mixing/blending of viscous liquids and pastes. The intense 2,000+ rpm motion moving the container in both rotational (“daily”) and revolutionary (“yearly”) directions creates homogenous blends. Also, efficient for degassing and powder dispersion.

Hero Products Group

Vancouver, Canada

604-522-6543

Fax: 604-522-8735

sales@hero.ca

www.hero.ca

S2650 5-Gallon Shaker

Attributes/comments: S2650 is a quiet, sturdy and reliable 5-gallon shaker with a small footprint that combines vibrational technology with a clamping system that thoroughly mixes from a 1/2 pint to a

5 gallon container, including cases; increasing efficiency and versatility.

Hockmeyer Equipment Corporation

Elizabeth City, NC USA

800-906-7278

Fax: 252-338-4705

sales@hockmeyer.com

www.hockmeyer.com

HHL Mixer

Attributes/Comments: The Hockmeyer HHL Mixer series can be dual or triple shaft units available in XP or TEFC configurations. There are high speed and low speed options available, including the helical sweep with patented dual reversible scraper.

Myers Mixers

Cudahy, CA USA

332-560-4723

Fax: 323-771-7789

sales@myersmixers.com

www.myersmixers.com

600/500 Series Horizontal Tank-

Mounted Mixer

Attributes/Comments: Myers Mixers introduces a horizontal mixer for intermediate-speed blending and mixing of viscous coatings. Eight bolt-on style blades homogenize the batch with minimal shear, while close tolerance between impellers and tank sidewall ensure batch uniformity, and the dimple-jacketed, ASME-rated tank provides an even batch temperature. Bolted end allows for simplified maintenance and cleaning.

Netzsch Premier Technologies, LLC

Exton, PA USA

484-879-2020

info.npt@netzsch.com

www.netzsch.com/gd

Epsilon Inline Disperser

Attributes/Comments: NETZSCH offers a new, compact solution for producing homogeneous dispersions with reproducible quality in an inline process. The dispersion process takes place in an atmospherically sealed processing chamber, and is dust and emission free.

Psi-Mix

Attributes/Comments: An inline disperser for wetting solid components on a large liquid surface, with emission- free, dust-free inline operation. The combination of vacuum dispersion, shearing and pressure wetting results in homogeneous, fine dispersions with very reproducible quality.

Reynolds Industries Inc.

Fort Mill, SC USA

803-548-4501

Fax: 803-792-9231

k.reynolds@reynoldsmixers.com

www.reyonoldsmixers.com

ASME Certified Manufacturer

Attributes/Comments: Reynolds Industries has been manufacturing tanks and vessels for 46 years. We are now ASME Certified with U, U2 and R certifications, allowing Reynolds to provide code stamped vessels to customers.

Sunin Machine Co., Ltd.

New Taipei City, Taiwan

+866-2-22407863

Fax: +886-2-22402596

Sunin168@ms31.hinet.net

www.sunin-machine.com

Dispersion Mixer

Attributes/Comments: Dispersion mixer is a machine suitable for work in narrow spaces in laboratories, with a handy and practical design. The double-purpose mixing cup can be cooled and heated through a pipe connector according to different formulas. The innovative working structure can realize both mixing and dispersion, and reduce material loss and environmental pollution during the transfer by peripheral pump.

Union Process Inc.

Akron, OH USA

330-929-3333

unionprocess@unionprocess.com

www.unionprocess.com

PTO-1000 Mixer (Pre-mix table)

Attributes/Comments: The PT-1000 pre-mix table is attached to the Union Process QL-100 Attritor for recirculation milling/mixing. Can be used to pre-mix thorough dispersion for various mixing or milling applications.

WAB US Corp.

Allendale, NJ USA

wab-us@wab-group.com

www.wab-group.com

The DYNO-MILL UBM:

Universal Bead Mill

Attributes/Comments: Covering the entire range from dispersion to micro/nano grinding, these new high-yield mills are suitable for grinding bead diameters from 0.2 to 2.5 mm, and allow for processing of high-viscosity products at a significantly increased production capacity.