Allison Skinner, Senior Certification Project Manager, NSF International11.02.18

When making purchasing decisions, it is now standard practice to consider the environmental impact of a product. To meet this demand, manufacturers not only need to ensure that their products have environmentally, economically and socially preferable life-cycle impacts, but also provide the information in a credible and transparent manner.

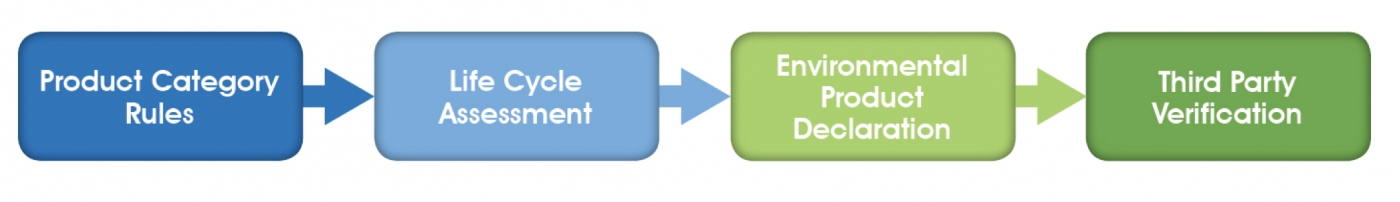

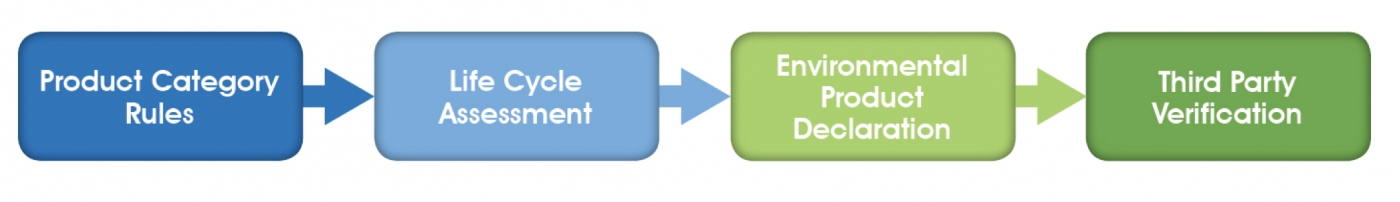

A primary method used to evaluate and compare these products is through an environmental product declaration (EPD), a standardized report based on a life cycle assessment (LCA) that transparently describes the inputs, manufacturing processes, environment impacts of a product across its entire life cycle, from cradle to grave.

An EPD is an ISO 14025 standardized report of data collected in the life cycle assessment (LCA) as specified by the product category rules (PCRs).

How are EPDs Used?

Verified EPDs are type III environmental product declarations that allow procurement professionals, architects, designers and consumers to objectively compare the environmental impact of a product throughout its full life cycle.

Manufacturers can assess the position of their products in the marketplace and respond to increasing demands for environmentally sustainable products and transparency in environmental claims.

EPDs may help building projects qualify for points through the LEED v4 in criteria for the Materials and Resources (MR) category (credit Building product disclosure and optimization - environmental product declarations) and the International Green Construction Code. EPDs are also increasingly required in international markets for consumer and commercial products.

EPDs in the Coatings Industry

Companies in the coatings industry use EPD’s to differentiate their products and demonstrate their commitment to creating sustainable coatings solutions, helping customers who are looking to use more sustainable products in their construction projects.

• AkzoNobel: Daniela Vlad, managing director of AkzoNobel's Powder Coatings business, on an EPD in their powder coatings business, "It underlines our commitment to creating sustainable coatings solutions and will help customers such as architects, developers and owners to gain LEED certification for their buildings. This is another step in offering our customers a very clean technology, which fits our ever-expanding sustainability ambitions."

• PPG: Earlier in 2018, PPG announced EPD verification for 15 formulas from an architectural sealants product line. PPG notes the demand for products that help customers reduce their carbon footprint and meet green building rating requirements such as LEED v4. EPD verification helps PPG meet their goal of offering a more environmentally friendly product portfolio.

• Roof Coatings Manufacturers Association (RCMA): In 2016, the Roof Coatings Manufacturers Association (RCMA) worked with NSF International to develop the first product category rule (PCR) in North America for roof coating materials. This PCR defines the environmental criteria for all subsequent EPD’s of roof coating products, supporting sustainability initiatives in the industry.

PCR Development

Before an EPD can be developed, a product category rule (PCR) must be written. A PCR sets the basis for comparison of different environmental product attributes among products in a specific category. Eligible program operators can guide industries, trade organizations or individual companies through an ISO 14025-compliant process to develop a PCR for their product categories.

Companies in the coatings industry looking to develop an EPD for their product could base them on the below PCR’s, among others:

• PCR for Building Related Products and Services with addenda for Paints and Varnishes and Coatings with Organic Binders

• PCR for Architectural Coatings: NAICS 325510

• RCMA PCR for Roof Coatings: NAICS 324122 & 325510

New PCR’s are always being developed. If your product is not covered under one of these PCRs, contact a Program Operator, such as NSF, to have one developed.

Third Party Verification

Third-party EPD verification demonstrates that the data was collected in accordance with the applicable PCR and meets all ISO requirements. The process, as performed by NSF International, generally involves:

1. LCA Critical Review

a. Verification body reviews the LCA to ensure it conforms with ISO 14040-44 and the relevant PCR

b. Verification body then provides feedback as needed

2. EPD Verification

a. Verification body reviews and verifies conformance of the EPD to ISO 14025 and the relevant PCR

b. Verification body then provides feedback as needed

3. Listing

a. EPD is listed on verification body website

b. Verified environmental aspects of product can be integrated into marketing materials, website and as part of sales strategy.

For further information go to: www.nsf.org.

A primary method used to evaluate and compare these products is through an environmental product declaration (EPD), a standardized report based on a life cycle assessment (LCA) that transparently describes the inputs, manufacturing processes, environment impacts of a product across its entire life cycle, from cradle to grave.

An EPD is an ISO 14025 standardized report of data collected in the life cycle assessment (LCA) as specified by the product category rules (PCRs).

How are EPDs Used?

Verified EPDs are type III environmental product declarations that allow procurement professionals, architects, designers and consumers to objectively compare the environmental impact of a product throughout its full life cycle.

Manufacturers can assess the position of their products in the marketplace and respond to increasing demands for environmentally sustainable products and transparency in environmental claims.

EPDs may help building projects qualify for points through the LEED v4 in criteria for the Materials and Resources (MR) category (credit Building product disclosure and optimization - environmental product declarations) and the International Green Construction Code. EPDs are also increasingly required in international markets for consumer and commercial products.

EPDs in the Coatings Industry

Companies in the coatings industry use EPD’s to differentiate their products and demonstrate their commitment to creating sustainable coatings solutions, helping customers who are looking to use more sustainable products in their construction projects.

• AkzoNobel: Daniela Vlad, managing director of AkzoNobel's Powder Coatings business, on an EPD in their powder coatings business, "It underlines our commitment to creating sustainable coatings solutions and will help customers such as architects, developers and owners to gain LEED certification for their buildings. This is another step in offering our customers a very clean technology, which fits our ever-expanding sustainability ambitions."

• PPG: Earlier in 2018, PPG announced EPD verification for 15 formulas from an architectural sealants product line. PPG notes the demand for products that help customers reduce their carbon footprint and meet green building rating requirements such as LEED v4. EPD verification helps PPG meet their goal of offering a more environmentally friendly product portfolio.

• Roof Coatings Manufacturers Association (RCMA): In 2016, the Roof Coatings Manufacturers Association (RCMA) worked with NSF International to develop the first product category rule (PCR) in North America for roof coating materials. This PCR defines the environmental criteria for all subsequent EPD’s of roof coating products, supporting sustainability initiatives in the industry.

PCR Development

Before an EPD can be developed, a product category rule (PCR) must be written. A PCR sets the basis for comparison of different environmental product attributes among products in a specific category. Eligible program operators can guide industries, trade organizations or individual companies through an ISO 14025-compliant process to develop a PCR for their product categories.

Companies in the coatings industry looking to develop an EPD for their product could base them on the below PCR’s, among others:

• PCR for Building Related Products and Services with addenda for Paints and Varnishes and Coatings with Organic Binders

• PCR for Architectural Coatings: NAICS 325510

• RCMA PCR for Roof Coatings: NAICS 324122 & 325510

New PCR’s are always being developed. If your product is not covered under one of these PCRs, contact a Program Operator, such as NSF, to have one developed.

Third Party Verification

Third-party EPD verification demonstrates that the data was collected in accordance with the applicable PCR and meets all ISO requirements. The process, as performed by NSF International, generally involves:

1. LCA Critical Review

a. Verification body reviews the LCA to ensure it conforms with ISO 14040-44 and the relevant PCR

b. Verification body then provides feedback as needed

2. EPD Verification

a. Verification body reviews and verifies conformance of the EPD to ISO 14025 and the relevant PCR

b. Verification body then provides feedback as needed

3. Listing

a. EPD is listed on verification body website

b. Verified environmental aspects of product can be integrated into marketing materials, website and as part of sales strategy.

For further information go to: www.nsf.org.