06.28.17

Axalta Coating Systems presented the opening address at the 24th annual DFO European Automotive Coating conference, held recently in Braunschweig, Germany, for automotive and paint industry experts. Sven Radek, Application Technology Manager for Axalta Coating Systems in its Europe, Middle East and Africa (EMEA) region, described Axalta’s selection of Harmonized Coating Technologies™ as a line of coating application processes integrating primers, basecoats and clear coats that can cut processing costs, save on material, and reduce the environmental footprint for light vehicle car original equipment manufacturers (OEMs).

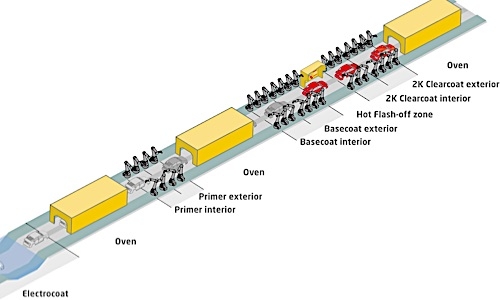

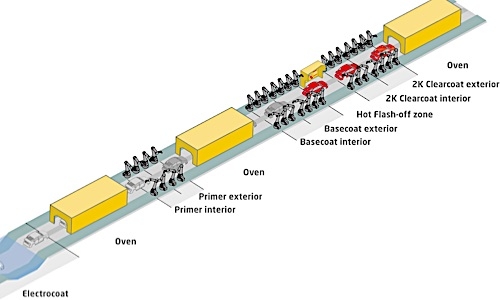

Titled Less is More, Radek’s presentation drew attention to the benefits of Axalta’s 3-Wet, 2-Wet and Eco-Concept Harmonized Coating TechnologiesTM for light vehicle OEM paint lines that can remove oven bake steps or combine layers. The conventional process, used for waterborne paints, requires the application of four paint layers, as well as the use of three curing ovens and one intermediate dryer.

“By contrast, Axalta’s Harmonized Coating Technologies telescope the entire light vehicle OEM paint process, making it possible to achieve outstanding results with just two ovens, and without either primer applications or sanding. This helps to save car manufacturers time, energy, labour, space and material,” Radek said, adding, “by 2018, 20 per cent of all cars are likely to be painted with consolidated processes.”

Axalta’s 3-Wet Process is a recent development whose features Radek explained at DFO. After the standard electrocoat application and oven curing, the 3-Wet process applies an exterior 1K or 2K pre-coat. This gives the final paint surface greater stone chip resistance, high UV protection and produces an outstanding finish. The solid colour precoats can be matched to different basecoat colour groups to create a uniform colour for further application steps. Under the 3-Wet process, there is no need for a primer as the precoat takes over the primer’s job.

As Radek explained, “the post-primer oven curing and sanding are not required either. Instead, the interior and exterior basecoats can be applied to the pre-coat after a short flash-off time.”

One of Axalta’s Harmonized Coating Technologies, known as Eco-Concept and used around the world since 2003, similarly eliminates the need for a primer oven and sanding on OEM paint lines. It provides good stone chip resistance and UV protection with a specially formulated 2K basecoat technology.

“We foresee an increasing global trend by light vehicle OEMs towards consolidated paint processes. In fact by 2020, we believe use of ambient flash waterborne 3-Wet processes will have risen by nine per cent,” Radek predicted.

“By contrast, Axalta’s Harmonized Coating Technologies telescope the entire light vehicle OEM paint process, making it possible to achieve outstanding results with just two ovens, and without either primer applications or sanding. This helps to save car manufacturers time, energy, labour, space and material,” Radek said, adding, “by 2018, 20 per cent of all cars are likely to be painted with consolidated processes.”

Axalta’s 3-Wet Process is a recent development whose features Radek explained at DFO. After the standard electrocoat application and oven curing, the 3-Wet process applies an exterior 1K or 2K pre-coat. This gives the final paint surface greater stone chip resistance, high UV protection and produces an outstanding finish. The solid colour precoats can be matched to different basecoat colour groups to create a uniform colour for further application steps. Under the 3-Wet process, there is no need for a primer as the precoat takes over the primer’s job.

As Radek explained, “the post-primer oven curing and sanding are not required either. Instead, the interior and exterior basecoats can be applied to the pre-coat after a short flash-off time.”

One of Axalta’s Harmonized Coating Technologies, known as Eco-Concept and used around the world since 2003, similarly eliminates the need for a primer oven and sanding on OEM paint lines. It provides good stone chip resistance and UV protection with a specially formulated 2K basecoat technology.

“We foresee an increasing global trend by light vehicle OEMs towards consolidated paint processes. In fact by 2020, we believe use of ambient flash waterborne 3-Wet processes will have risen by nine per cent,” Radek predicted.