12.17.18

Evonik Corporation’s High Performance Polymers Business Line expressed its approval of the recent decision by the U.S. Department of Transportation’s Pipeline and Hazardous Material Safety Administration (PHMSA) on the issuance of a final rule that amends the Federal Pipeline Safety Regulations for plastics piping systems to include updated standards governing the use for pipelines made of polyamide 12 (PA12) thermoplastic.

The updates in the final rule are intended to enhance public safety, allow for the expanded use of plastic pipe products in the transportation of natural or other gas, and allow or require the use of certain materials and practices.

“The addition of Polyamide 12 to the federal code provides new material options that offer proven, safe and cost saving alternatives for local natural gas distributors seeking to install new, repaired, or replaced pipelines operating at up to 250 psig," said Doug Weishaar, business development manager of Evonik’s High Performance Polymers Business Line.

The updates in the final rule are intended to enhance public safety, allow for the expanded use of plastic pipe products in the transportation of natural or other gas, and allow or require the use of certain materials and practices.

“The addition of Polyamide 12 to the federal code provides new material options that offer proven, safe and cost saving alternatives for local natural gas distributors seeking to install new, repaired, or replaced pipelines operating at up to 250 psig," said Doug Weishaar, business development manager of Evonik’s High Performance Polymers Business Line.

“U.S. regulatory guidelines are typically viewed as more conservative versus other regions of the world. The inclusion of PA12 into this federal standard further demonstrates the proven performance record of this material,” added Markus Hartmann, head of Segment Oil & Gas for High Performance Polymers.

As a result of the final rule’s updated changes, the cost of materials to produce new pipe is estimated to be reduced by 10 percent, resulting in an annual material cost savings of approximately $32 million for transmission, gathering, and distribution operators, according to PHMSA.

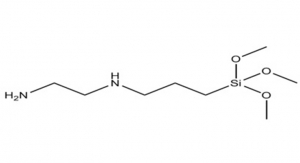

VESTAMID NRG polyamide 12 compounds are specially developed for the oil and gas industry. As well as high impact strength, it also boasts exceptional resistance to stress cracking and chemicals. Thanks to these properties, the compounds can be used to protect both the interior and exterior of onshore and offshore oil and gas pipes to provide safe service during the lifetime of the installed pipeline.

As a result of the final rule’s updated changes, the cost of materials to produce new pipe is estimated to be reduced by 10 percent, resulting in an annual material cost savings of approximately $32 million for transmission, gathering, and distribution operators, according to PHMSA.

VESTAMID NRG polyamide 12 compounds are specially developed for the oil and gas industry. As well as high impact strength, it also boasts exceptional resistance to stress cracking and chemicals. Thanks to these properties, the compounds can be used to protect both the interior and exterior of onshore and offshore oil and gas pipes to provide safe service during the lifetime of the installed pipeline.