11.20.19

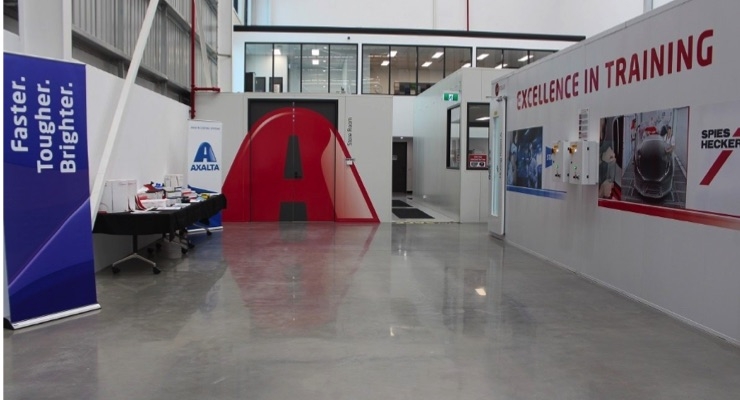

Axalta officially opened the doors of its 1,000-square-meter (10,763.9-square-foot) regional customer training center – the "RTC" – in Western Sydney.

The training facility was inaugurated by Sobers Sethi, president, Emerging Markets, Axalta.

“The new training facility uses the latest coating technologies, industry-leading training techniques, and advanced digital equipment to enable repairers to deliver the highest quality refinish, enabling our customers to be more efficient, productive, and profitable," Sethi said. "We help our customers drive these improvements while also being mindful of the environment with sustainable techniques and products.”

Local customers and partners were invited to see the latest products in action and view the cutting edge environment which includes industry-leading equipment.

“Simply put, the new training facility offers the best training available in the region,” said Steven Brett, managing director of Axalta Coating Systems in Australia. “Axalta is a world leader in refinish and is consistently making significant investments, like the RTC, to enhance our capabilities and facilities to help customers grow their businesses.”

The training center is well equipped with two state-of-the-art USI Chronotech spray booths, as well as three USI full downdraft preparation areas with USI rail track system for easy vehicle side loading. The three prep bays can be divided by electric curtains. Also featuring three USI paint mix rooms with an additional large cleaning room and a USI spray box-booth for test panels and color card spray outs, there are plenty of opportunities for attendees to apply their practical knowledge.

When attendees aren’t using the latest products and equipment, they will be learning from Axalta trainers in a theory room with the latest audio-visual equipment that can seat up to 20. The new facility also includes a storeroom for all consumables and tools, along with an air-conditioned lunch and kitchen area with modern facilities.

The training facility was inaugurated by Sobers Sethi, president, Emerging Markets, Axalta.

“The new training facility uses the latest coating technologies, industry-leading training techniques, and advanced digital equipment to enable repairers to deliver the highest quality refinish, enabling our customers to be more efficient, productive, and profitable," Sethi said. "We help our customers drive these improvements while also being mindful of the environment with sustainable techniques and products.”

Local customers and partners were invited to see the latest products in action and view the cutting edge environment which includes industry-leading equipment.

“Simply put, the new training facility offers the best training available in the region,” said Steven Brett, managing director of Axalta Coating Systems in Australia. “Axalta is a world leader in refinish and is consistently making significant investments, like the RTC, to enhance our capabilities and facilities to help customers grow their businesses.”

The training center is well equipped with two state-of-the-art USI Chronotech spray booths, as well as three USI full downdraft preparation areas with USI rail track system for easy vehicle side loading. The three prep bays can be divided by electric curtains. Also featuring three USI paint mix rooms with an additional large cleaning room and a USI spray box-booth for test panels and color card spray outs, there are plenty of opportunities for attendees to apply their practical knowledge.

When attendees aren’t using the latest products and equipment, they will be learning from Axalta trainers in a theory room with the latest audio-visual equipment that can seat up to 20. The new facility also includes a storeroom for all consumables and tools, along with an air-conditioned lunch and kitchen area with modern facilities.