Rob Lagendijk, R&D Director for Automotive & Specialty Coatings, AkzoNobel10.11.21

Vehicle Refinishing is considered by many as a form of art, such is the skill of the collision shop teams who return a battered and damaged car to its owner in showroom condition.

And while a satisfied customer is of course the only outcome that really matters, if delivering customer satisfaction can be married with faster key-to-key times and a “right the first time” color match within the collision shop itself, then not only do you have happy customers, but you also have the foundation for a successful, growing and profitable business.

A premium quality finish does not happen by chance. On the one hand, it comes down to the skill of the individual painter. On the other, it depends on the skill of the manufacturer in harnessing years of investment in Research & Development (R&D) to bring new products to market.

It’s why new resins are being developed, for example, with faster drying times and/or providing better coverage, and that are more sustainable without sacrificing performance. And it’s why laboratory testing regimes have evolved and become more stringent, with the introduction of sophisticated robotics and automated weathering machines to test new products to the limit.

Manufacturers recognize that a coating not only has to look good, it also has to perform. They also recognize that the collision shop must perform too, which is why R&D is not limited to the product alone but also embraces technology that is focused on making collision shops more efficient. It’s why new color retrieval tools are being developed. It’s also why there’s a shift toward greater digitalization and connectivity within individual collision shops or across an entire portfolio to enhance project management and take productivity and operational effectiveness to new levels.

Changing customer demand

In many industries, customers drive innovation, and this is especially true in Vehicle Refinishing, where the trend is towards even greater process efficiency.

We see collision shops, especially in North America and Europe, applying lean management principles such as the 5S system (sort, set in order, shine, standardize and sustain) to make workshops cleaner and more efficient. To this end, manufacturers are also supporting the efficiency agenda by creating new coatings that are even easier to use, further driving productivity and reducing key-to-key times, repairing more cars more quickly.

The constant introduction of new vehicle makes and models means it is even more important to keep up to speed with new color trends. Collision shops need to be able to retrieve a color for any vehicle, of any age, anywhere in the world – with total accuracy. The rise of electric vehicles is also adding further levels of complexity to the repair process as they require specialists trained in dealing with high-voltage technologies.

Customers drive a greater focus on business performance, obliging collision shops to standardize processes where possible, and demand more from manufacturers in the speed and ease with which products can be applied. Customers also drive innovation in terms of R&D; and this, in turn, has led to two significant trends in resin development: one is centered on drying times; and the second on sustainability, although the two are inextricably linked.

Resin developments

Achieving faster drying times at lower temperatures has been a key focus for some time. R&D in this space has accelerated significantly in recent years, especially around the use of UV and ambient curing technology. The ability for a product to dry more rapidly has an obvious knock-on effect in terms of productivity and faster throughput, which – in a busy collision shop – can translate into significant additional revenue. Additionally, further advantages are gained by lower energy costs, and the work that is going in to creating products with a longer pot-life to further reduce unnecessary waste and cost.

Increasing the solid content of resins helps improve coverage and reduce emission levels. This too is a major advantage for those seeking to gain a competitive edge and meet future sustainability targets.

In other areas, manufacturers have been developing more bio-based coating technologies that emit lower levels of volatile organic compounds (VOCs) and this trend will continue.

More productive paint systems that help reduce a collision shop’s carbon footprint will also be in demand.

Scientists are actively working on ways of exchanging raw materials for “greener” alternatives, but in such a way that the coating’s binding properties are not affected. A breakthrough innovation was announced in December 2020 whereby traditional oil-based monomers could be replaced by bio-based monomers to make resins. Requiring just UV light, oxygen and renewable raw materials, patent applications have already been filed for resins and coatings made with monomers derived from sugar derivatives isolated from biomass.

Although the work is still at a relatively early stage, experts predict that the first of this new generation of products could be on the market within the next five years, and by 2040/50 there’s every chance that a business like AkzoNobel might only be using bio-based monomers in its resin production.

There is, perhaps, a third trend that is worth highlighting in terms of the characteristics of future coatings, and that is in relation to e-mobility and autonomous driving. RADAR is playing an important role in shaping future transportation needs, and the transparency of the coating for RADAR signals is critical to ensuring that a vehicle’s sensors perform without any interference. Similarly, the future introduction of LiDAR (which works on the same principle as RADAR but uses light from a laser) will also require coatings to be able to reflect light sufficiently to enhance effectiveness of future road safety systems.

Laboratory testing regimes

A significant trend in recent years is the shift towards more sophisticated, digitally-based test regimes as part of the R&D process to develop new coatings meeting the highest

quality standards.

To make sure our coatings can withstand the extremes of weather, we are using the latest generation of the Weather Ometer. The weather testing instrument combines optical and digital technologies to expose our products to various temperatures and sunlight from highly humid to dry conditions.

The Weather Ometer can also predict the impact of humidity and condensation or spray water on exposed areas to simulate rain to induce temperature shock and the effects of erosion. The results are highly accurate, reproduceable and repeatable, and help us to predict the service life of our coatings.

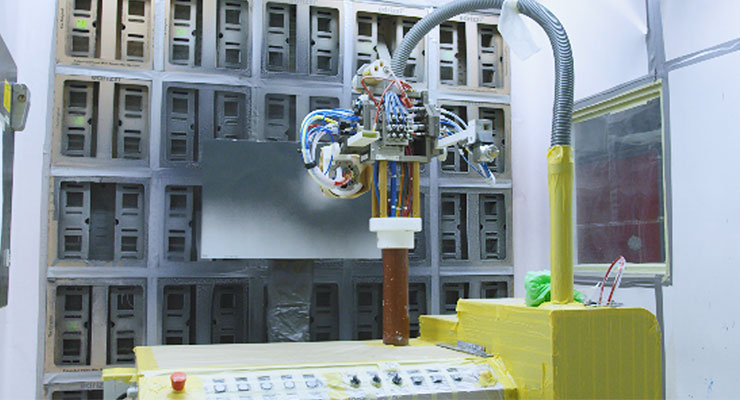

The methods by which a coating is applied can also be modelled and tested by using a robot. A paint robot is a highly versatile piece of equipment that replicates the application process and can switch between application processes and equipment.

A paint robot can also control spray patterns – air and material flow very accurately – far more accurately than can be achieved manually, as well as being able to reproduce results to a consistent quality. This is something that is particularly important in a laboratory environment. It is especially helpful in designing discriminating tests to show the effects of

recipe changes.

Enhanced digitalization

The trend toward greater use of systems and digital technology is not restricted to coating production and testing. It is a similarly critical element of the color retrieval process. Indeed, this is an area that is having an effect that is little short of revolutionary when it comes to further improving collision shop workflow and a “right the first time” color match.

Among the most recent innovations includes one from AkzoNobel itself and the launch of a digital color retrieval software known as MIXIT. MIXIT, which can seamlessly integrate with AkzoNobel’s spectrophotometer – Automatchic Vision™, provides collision shops with access to a global color database of more than two million formulas. This cloud-based technology is updated in real time with new colors and variants, so customers are always up-to-date.

(Just to put the scale of the challenge into context, whereas color matching is now predominantly an automated, digital process, some manual matching is still undertaken. Every year AkzoNobel technicians create between 15,000 – 20,000 formulas manually and perhaps 20 times that number digitally.)

Driven by intelligent algorithms, MIXIT delivers fast and accurate search results, enhancing the workflow for painters and providing new functionalities for collision shop managers. MIXIT helps businesses by delivering real-time insights through live dashboards and reports. For example, a collision shop manager can get information about the material allocation against the work orders to calculate the cost per repair and can access this data from anywhere with any device. A painter, on the other hand, can share custom color formulas through the Cloud across their network, enhancing the know-how of colleagues at other locations.

Further future innovations and thoughts

So what of the future?

Technology is important, but so too is experience. Alongside the robots and automated systems that are now an intrinsic part of Industry 4.0, the skill of the individual is still very much

in demand – whether that’s within the manufacturer, the scientists developing new resins, or at the collision shop, and the highly-skilled car body painters whose skills are such an essential part of achieving a successful customer outcome.

Future coatings will be more sustainable. New, low VOC coatings are continually being developed in line with constantly evolving global standards, but that also offer improvements in gloss, film build, drying time, ease of use and durability. These new coatings are not only helping collision shops to reduce potentially harmful emissions but also achieve long-term business profitability.

Continuing the sustainability theme, a clear direction of travel is towards new waterborne basecoat systems that have a wider application window and no need for special additives. Since no solvents are present to evaporate, processing times will be even further reduced, and the consumption of materials minimized.

Current and future UV and ambient curing technologies will also help further improve collision shop throughput and performance, as well as reducing energy consumption, with one new UV filler technology allowing curing in as little as five minutes. These innovations, alongside alternative drying options, are giving collision shop owners even greater flexibility in terms of managing throughput and efficiency and in freeing up spray booth capacity when it is needed.

Further digitization will also be a trend. The ability to connect color retrieval systems via WiFi to smart devices, for example, is now fast becoming commonplace, and even greater use will be made globally of collision shop workflow control solutions (for example AkzoNobel’s Carbeat™ application to enable repair shops to track each job as it progresses through their facility, maximizing the processing of multiple vehicles much more efficiently).

New solutions that have only recently been launched will also become more mainstream, including Connect, an Application Programming Interface (API) that facilitates the exchange of data between AkzoNobel’s digital applications and third-party software applications used by collision repair customers. This is just one example of how in the near future, all digital solutions in a collision shop will be “connected” to create a complete digital “ecosystem,” driving process efficiency and delivering information that enables data-driven decision making and planning.

Vehicle refinishing businesses face numerous challenges, and collision shops, insurance companies, OEMs and other partners will need to work collectively and collaboratively to ensure the needs of every stakeholder are addressed. Future trends in vehicle refinishing will therefore continue to focus on finding new ways for owners to do more with less, to become even more productive and sustainable, and reduce energy consumption and costs, and where “right the first time” is business as usual. CW

For further information please visit www.Sikkensvr.com/en-us

The accompanying video featuring Rob Lagendijkcan be viewed via the unlisted Youtube link here: https://youtu.be/R5FX1wIS8cc

And while a satisfied customer is of course the only outcome that really matters, if delivering customer satisfaction can be married with faster key-to-key times and a “right the first time” color match within the collision shop itself, then not only do you have happy customers, but you also have the foundation for a successful, growing and profitable business.

A premium quality finish does not happen by chance. On the one hand, it comes down to the skill of the individual painter. On the other, it depends on the skill of the manufacturer in harnessing years of investment in Research & Development (R&D) to bring new products to market.

It’s why new resins are being developed, for example, with faster drying times and/or providing better coverage, and that are more sustainable without sacrificing performance. And it’s why laboratory testing regimes have evolved and become more stringent, with the introduction of sophisticated robotics and automated weathering machines to test new products to the limit.

Manufacturers recognize that a coating not only has to look good, it also has to perform. They also recognize that the collision shop must perform too, which is why R&D is not limited to the product alone but also embraces technology that is focused on making collision shops more efficient. It’s why new color retrieval tools are being developed. It’s also why there’s a shift toward greater digitalization and connectivity within individual collision shops or across an entire portfolio to enhance project management and take productivity and operational effectiveness to new levels.

Changing customer demand

In many industries, customers drive innovation, and this is especially true in Vehicle Refinishing, where the trend is towards even greater process efficiency.

We see collision shops, especially in North America and Europe, applying lean management principles such as the 5S system (sort, set in order, shine, standardize and sustain) to make workshops cleaner and more efficient. To this end, manufacturers are also supporting the efficiency agenda by creating new coatings that are even easier to use, further driving productivity and reducing key-to-key times, repairing more cars more quickly.

The constant introduction of new vehicle makes and models means it is even more important to keep up to speed with new color trends. Collision shops need to be able to retrieve a color for any vehicle, of any age, anywhere in the world – with total accuracy. The rise of electric vehicles is also adding further levels of complexity to the repair process as they require specialists trained in dealing with high-voltage technologies.

Customers drive a greater focus on business performance, obliging collision shops to standardize processes where possible, and demand more from manufacturers in the speed and ease with which products can be applied. Customers also drive innovation in terms of R&D; and this, in turn, has led to two significant trends in resin development: one is centered on drying times; and the second on sustainability, although the two are inextricably linked.

Resin developments

Achieving faster drying times at lower temperatures has been a key focus for some time. R&D in this space has accelerated significantly in recent years, especially around the use of UV and ambient curing technology. The ability for a product to dry more rapidly has an obvious knock-on effect in terms of productivity and faster throughput, which – in a busy collision shop – can translate into significant additional revenue. Additionally, further advantages are gained by lower energy costs, and the work that is going in to creating products with a longer pot-life to further reduce unnecessary waste and cost.

Increasing the solid content of resins helps improve coverage and reduce emission levels. This too is a major advantage for those seeking to gain a competitive edge and meet future sustainability targets.

In other areas, manufacturers have been developing more bio-based coating technologies that emit lower levels of volatile organic compounds (VOCs) and this trend will continue.

More productive paint systems that help reduce a collision shop’s carbon footprint will also be in demand.

Scientists are actively working on ways of exchanging raw materials for “greener” alternatives, but in such a way that the coating’s binding properties are not affected. A breakthrough innovation was announced in December 2020 whereby traditional oil-based monomers could be replaced by bio-based monomers to make resins. Requiring just UV light, oxygen and renewable raw materials, patent applications have already been filed for resins and coatings made with monomers derived from sugar derivatives isolated from biomass.

Although the work is still at a relatively early stage, experts predict that the first of this new generation of products could be on the market within the next five years, and by 2040/50 there’s every chance that a business like AkzoNobel might only be using bio-based monomers in its resin production.

There is, perhaps, a third trend that is worth highlighting in terms of the characteristics of future coatings, and that is in relation to e-mobility and autonomous driving. RADAR is playing an important role in shaping future transportation needs, and the transparency of the coating for RADAR signals is critical to ensuring that a vehicle’s sensors perform without any interference. Similarly, the future introduction of LiDAR (which works on the same principle as RADAR but uses light from a laser) will also require coatings to be able to reflect light sufficiently to enhance effectiveness of future road safety systems.

Laboratory testing regimes

A significant trend in recent years is the shift towards more sophisticated, digitally-based test regimes as part of the R&D process to develop new coatings meeting the highest

quality standards.

To make sure our coatings can withstand the extremes of weather, we are using the latest generation of the Weather Ometer. The weather testing instrument combines optical and digital technologies to expose our products to various temperatures and sunlight from highly humid to dry conditions.

The Weather Ometer can also predict the impact of humidity and condensation or spray water on exposed areas to simulate rain to induce temperature shock and the effects of erosion. The results are highly accurate, reproduceable and repeatable, and help us to predict the service life of our coatings.

The methods by which a coating is applied can also be modelled and tested by using a robot. A paint robot is a highly versatile piece of equipment that replicates the application process and can switch between application processes and equipment.

A paint robot can also control spray patterns – air and material flow very accurately – far more accurately than can be achieved manually, as well as being able to reproduce results to a consistent quality. This is something that is particularly important in a laboratory environment. It is especially helpful in designing discriminating tests to show the effects of

recipe changes.

Enhanced digitalization

The trend toward greater use of systems and digital technology is not restricted to coating production and testing. It is a similarly critical element of the color retrieval process. Indeed, this is an area that is having an effect that is little short of revolutionary when it comes to further improving collision shop workflow and a “right the first time” color match.

Among the most recent innovations includes one from AkzoNobel itself and the launch of a digital color retrieval software known as MIXIT. MIXIT, which can seamlessly integrate with AkzoNobel’s spectrophotometer – Automatchic Vision™, provides collision shops with access to a global color database of more than two million formulas. This cloud-based technology is updated in real time with new colors and variants, so customers are always up-to-date.

(Just to put the scale of the challenge into context, whereas color matching is now predominantly an automated, digital process, some manual matching is still undertaken. Every year AkzoNobel technicians create between 15,000 – 20,000 formulas manually and perhaps 20 times that number digitally.)

Driven by intelligent algorithms, MIXIT delivers fast and accurate search results, enhancing the workflow for painters and providing new functionalities for collision shop managers. MIXIT helps businesses by delivering real-time insights through live dashboards and reports. For example, a collision shop manager can get information about the material allocation against the work orders to calculate the cost per repair and can access this data from anywhere with any device. A painter, on the other hand, can share custom color formulas through the Cloud across their network, enhancing the know-how of colleagues at other locations.

Further future innovations and thoughts

So what of the future?

Technology is important, but so too is experience. Alongside the robots and automated systems that are now an intrinsic part of Industry 4.0, the skill of the individual is still very much

in demand – whether that’s within the manufacturer, the scientists developing new resins, or at the collision shop, and the highly-skilled car body painters whose skills are such an essential part of achieving a successful customer outcome.

Future coatings will be more sustainable. New, low VOC coatings are continually being developed in line with constantly evolving global standards, but that also offer improvements in gloss, film build, drying time, ease of use and durability. These new coatings are not only helping collision shops to reduce potentially harmful emissions but also achieve long-term business profitability.

Continuing the sustainability theme, a clear direction of travel is towards new waterborne basecoat systems that have a wider application window and no need for special additives. Since no solvents are present to evaporate, processing times will be even further reduced, and the consumption of materials minimized.

Current and future UV and ambient curing technologies will also help further improve collision shop throughput and performance, as well as reducing energy consumption, with one new UV filler technology allowing curing in as little as five minutes. These innovations, alongside alternative drying options, are giving collision shop owners even greater flexibility in terms of managing throughput and efficiency and in freeing up spray booth capacity when it is needed.

Further digitization will also be a trend. The ability to connect color retrieval systems via WiFi to smart devices, for example, is now fast becoming commonplace, and even greater use will be made globally of collision shop workflow control solutions (for example AkzoNobel’s Carbeat™ application to enable repair shops to track each job as it progresses through their facility, maximizing the processing of multiple vehicles much more efficiently).

New solutions that have only recently been launched will also become more mainstream, including Connect, an Application Programming Interface (API) that facilitates the exchange of data between AkzoNobel’s digital applications and third-party software applications used by collision repair customers. This is just one example of how in the near future, all digital solutions in a collision shop will be “connected” to create a complete digital “ecosystem,” driving process efficiency and delivering information that enables data-driven decision making and planning.

Vehicle refinishing businesses face numerous challenges, and collision shops, insurance companies, OEMs and other partners will need to work collectively and collaboratively to ensure the needs of every stakeholder are addressed. Future trends in vehicle refinishing will therefore continue to focus on finding new ways for owners to do more with less, to become even more productive and sustainable, and reduce energy consumption and costs, and where “right the first time” is business as usual. CW

For further information please visit www.Sikkensvr.com/en-us

The accompanying video featuring Rob Lagendijkcan be viewed via the unlisted Youtube link here: https://youtu.be/R5FX1wIS8cc