Kerry Pianoforte, Editor05.08.23

As the airline industry begins to recover from the effects of the pandemic, the aerospace coatings market has experienced growth in 2022. Although there are still a number of obstacles to overcome, there are indications that the market will make a full recovery within the next two years.

“The airline industry, aircraft OEMs and the aerospace coatings market are on a growth trajectory, but the challenges are not yet behind us, especially when it comes to the supply chain,” said Tami Swearingin, managing director for AkzoNobel Global Aerospace and Film. “Issues on a local and global scale, from the Texas freeze to the COVID-19 pandemic, have conspired to make a challenging time more difficult still. And with the ongoing conflict in Ukraine, the ability to be able to predict what happens next with any great certainty has been largely thrown out of the window.

“David Calhoun, the CEO at Boeing, expects supply chain issues within his business to continue to the end of 2023,” Swearingin noted. “Guillaume Faury, CEO of Airbus, also talks about the ‘depth and magnitude’ of recent crises as being particularly unusual, and admits to struggling with shortages of raw materials, electronic components and other parts. Airbus and Boeing are not alone. The leaders at Safran and Raytheon have also recently gone on record citing supply chain issues, and we can all, in this industry, share their pain. But we can also share their optimism and belief that our industry is on the road to recovery. Our best prediction at this time is to see a full recovery by 2024/2025.”

“The airline industry has recovered 90% from the pandemic levels in most parts of the world, with China lagging a little behind,” said Duane Utter, PPG OEM segment manager, aerospace coatings. PPG has seen a strong coatings market since early 2021. Demand continues to recover, leading to strong year-over-year organic sales growth of about 20% in Q4 2022, even though certain supply chain challenges remained.

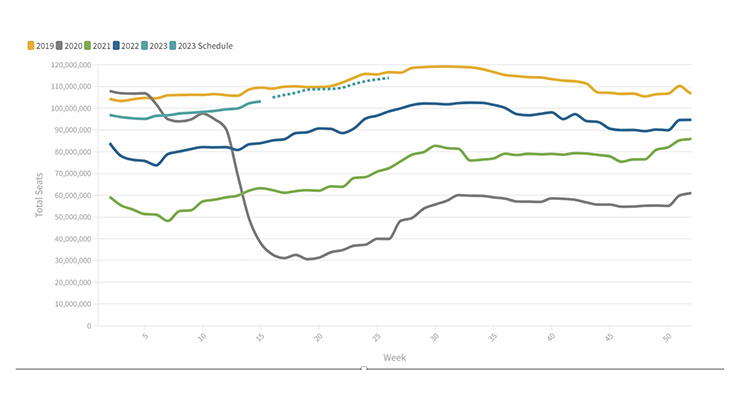

According to Utter, airlines are well on their way to full recovery, but are still somewhat challenged with the staffing of crews, pilots and flight attendants, as well as ground crew and airport staff. These problems should resolve as the public continues to increase air travel, especially to foreign destinations. OAG (COVID-19 Airline Recovery | OAG) has tracked weekly air travel data during the last four years. This resource shows recent levels to be within 6 percent of 2019 pre-pandemic levels.

Mankiewicz Coatings is a global coatings manufacturer active in many industries. One is aviation, where they develop, produce and supply coatings for cabin interiors, exteriors and structural parts globally.

Last year, increasing business in the aviation industry that reached pre-pandemic levels could be observed. There were differences in the timing of this comeback, which started in the U.S., followed directly by Europe and Asia. Due to the tight corona rules in China, there were the biggest hold-ups, but the Chinese aviation industry is also experiencing strong growth.

The aviation supply chain, which has been severely cut back during COVID, is sometimes facing challenges in meeting this sudden spike in growth. “Through many measures, we have been able to retain the vital staff in all areas and so we are in the fortunate position of being ready for growth on our part,” said René Lang, executive managing director Aviation at Mankiewicz Coatings. “The business has become more global due to increased demand, though. Free maintenance slots are being used – no matter which end of the world they are available. Considering that we make individual bespoke suits in paint for our customers, it’s a big challenge to switch quickly and schedule the planned paint jobs in the U.S. now for China but through smart planning and clear communication, we are happy to make it happen again and again.”

Speaking about the supply chain, Mankiewicz is very proud to recently having received an SQIP Award from Airbus for its excellent performance in the “Materials and Parts” category. The award is presented annually to companies that have distinguished themselves through exceptional performance in the areas of product quality and delivery reliability. SQIP stands for “Supply Chain & Quality Improvement Program.” Mankiewicz has already received several awards from Airbus for outstanding delivery performance but this year they received the highest: the paint manufacturer was recognized as an “Accredited Supplier.” This award is only given if the supplier delivers supply chain excellence over more than two years.

Lang commented, “We are very thankful for our team and this special achievement. To maintain this top performance for several years in a row and not make any mistakes is something that makes me very proud and speaks for the high commitment of the Mankiewicz team. To supply products in this industry is already a high bar, and being among the best is terrific.”

Aerospace coatings consumers need to make sure the products they use deliver the highest performance.

“Commercial airlines are subjected to extremes of heat, cold, rain, lightning, sand, pressure, etc. – some of the harshest conditions imaginable,” said Swearingin. “Creating a single coating that protects everything is a challenge, but a coating system comprised of multiple components, each with a specific function, is possible, and can be very effective. Performance is primarily driven by the polymer network – the resins which keep the pigments together, providing overall cohesion of the paint film and adhesion to the substrate. They also give the coating its performance and durability. Formulating a coating that delivers at 40,000 feet or at Mach 0.86 is achieved through our in-house polymer synthesis capability to design and manufacture custom resins. We create a layer of multiple coatings, each with specific capabilities, that together act as multiple protective layers below the visible paint. The hardest working, toughest, and most technically advanced coatings are the ones that will never be seen by anyone but the applicator.”

“Thanks to strong, well-established relationships, and PPG’s coatings and sealants platform, our science and technology (S&T) teams are in constant contact with customers to better understand their evolving needs and the key drivers shaping the future of aviation, including productivity, efficiency and safety,” said Robin Peffer, PPG global product manager, aerospace coatings. “We leverage this feedback to evaluate our design profiles and formulations, to ensure that we’re delivering innovative products that protect and beautify – improving asset aesthetics while creating efficiencies, such as weight savings, and supporting compliance with future environmental, health and safety (EHS) regulations.”

Environmentally-preferred solutions are a top priority for PPG’s customers and its business. “We’ve sought to replace certain substances, such as chrome, with more eco-friendly alternatives, without sacrificing product performance,” said Peffer. “Furthermore, to better reach our customers and provide excellence service, PPG has a global network of 16 application support centers (ASCs). A 17th ASC will open in Toulouse, France, in the fourth quarter of 2023. Each ASC serves our customers on a regional level and is strategically located near aerospace hubs. The ASCs play a key role in supporting both large, commercial OEMs and aftermarket maintenance of aircraft by providing sealants, coatings, application equipment and repackaging of sealants and coatings for right-sized application.”

In aviation, the subject of weight continues to be at the core of requirements. “Every kg more means more kerosene consumption,” said Lang. “Kerosene is the most significant cost driver and CO2 emissions are directly related. This is therefore the biggest driver of sustainability and efficiency for airlines. In this context, as an example, coatings play a crucial role by replacing heavy with lightweight materials. Coatings can simulate metals or frosted glass, for example. Mankiewicz has an extensive portfolio of effect coatings that give the airline or manufacturer a free choice of combination in terms of color tone, effect, gloss level and touch effects. All coatings have one thing in common: they save weight and create opportunities for individualization and a feel-good factor in the air.”

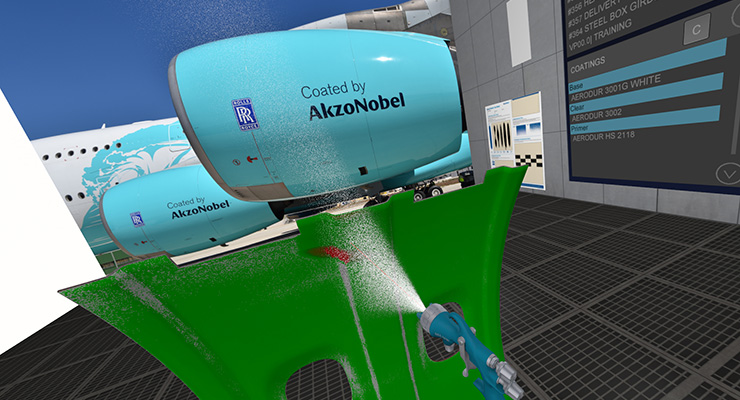

“Paint users are grateful for the robustness of our systems,” Lang continued. “In interior, exterior and structural parts, it is essential to have large painting windows and to be able to use all possible painting methods. In addition, a repair capability is necessary for painting and flight operations. It is crucial that these are also well documented and trained and that paint solutions are available in small quantities in the right color and effect. Mankiewicz is very proud of its experienced global technical service crew, which optimizes painting processes on-site at the customer’s premises and makes painters fit for the job.”

As aerospace coatings products evolve, the frequency of the need to repaint has decreased.

Swearingin noted that external coatings have evolved rapidly in the last decade from single stage to basecoat/clearcoat systems, extending the need to repaint some aircraft for up to ten years or even more. Despite this, aircraft still tend to be taken out of service for maintenance every six or seven years without really knowing if a repaint is needed.

To address this issue AkzoNobel has launched Aerofleet Coatings Management, a new digital, data-driven service that helps airlines and other large operators to tailor and optimize the coatings’ replacement and maintenance schedule for individual aircraft within an airline fleet. It captures the data from both manual inspections and drone-operated inspections, creating a database of every aircraft in a fleet. The history includes details of the coatings used (e.g. single stage or basecoat/clearcoat coatings) along with flight path data (e.g. weather conditions etc.) which affect the integrity/longevity of the coating applied.

“By analyzing the captured information (e.g dry film thickness, color variation, gloss and general appearance), and mapping it over time, a more accurate maintenance and repaint schedule can be calculated and it becomes easier and more accurate to determine when an aircraft needs to be repainted, rather than simply using time or flight hours,” said Swearingin. “Schedules can be created that balance the practical performance of a coating and where the aircraft in a fleet are being operated (i.e. the different flight paths, distances, altitudes, environment etc.) against the aesthetic/marketing (i.e. branding) and business needs of the airline.”

“Often, planes are repainted whilst the coating still has life left in it,” Swearingin added. “Using our service will reduce costs while increasing aircraft availability by anything up to a year. Over time, the frequency with which aircraft need to be repainted will fall, which is significantly better for an airline’s bottom line, and better for the planet.”

Paint is a very important part of the aircraft. “While beautifying it and influencing the airline’s public image, it must protect for certain environmental and chemical conditions,” said Peffer. The primer used under the topcoat helps with corrosion and fluid resistance. Airlines typically repaint after approximately six to eight years, but that is being extended due to newer technology topcoats such as PPG’s DESOTHANE HD CA9007 and DESOTHANE HD 9008 basecoat/clearcoat systems.

Military aircraft are usually painted every four top six years, as the topcoat is designed for survivability. The primers feature the corrosion and fluid resistance seen on commercial aircraft, with additional IR reflectance to resist heat in extreme conditions.

Notably, PPG recently announced a collaboration with Aerobrand, a UK airline brand and design consultancy, to assist airlines customers with new coatings schemes and one-off special liveries. The new Livery Lab system will enable airlines to work closely with designers to create custom paint colors, give direct input on livery design, and manage all aspects of the livery change process.

According to Lang, typically an aircraft flies around for more than seven years with modern paint systems. “We monitored several aircraft that have been painted with our ALEXIT BaseCoat/ClearCoat paint system that have now been flying for more than ten years and some for even more than 13 years and still have a good gloss and their exterior skin is pretty intact. This is twice as long as required and usual. This is a significant achievement, as it saves the airline considerable money.”

In addition to the standard repaints after a certain period, livery changes/rebrandings, lease endings, and sales often require paint jobs out of sequence.

“We are very proud of the implemented rebrandings or the many airline start-ups and the corresponding livery consulting,” said Lang. “Here, our in-house designers and colorimetric experts work hand-in-hand with the customer to develop great ideas, which are reliably brought to life with the support of our experienced technicians.”

“Next to the minimum seven years that the exterior coating system on the fuselage must remain glossy, performant and durable, there are also the wings, which in the past often needed to be overhauled much sooner, as they suffered considerable gloss losses and repairs were always visible,” said Lang. “In contrast to the high-gloss BaseCoat/ClearCoat systems used on the fuselage, semi-gloss topcoats are traditionally used on the wings. The stresses are also different: the wings move a lot and hydraulic and de-icing fluids and kerosene also cause chemical stress. Challenging demands are placed on a coating system regarding flexibility, UV exposure and chemical resistance.”

Lang noted that in the past, this was solved with two different topcoats, a flexible one for the top side and a very chemical-resistant one for the bottom side. “Mankiewicz has designed a dedicated wing coat that for the first time, meets the requirements of both wing sides and is also repairable: ALEXIT WingFlex. More efficient processes can be realized with the 2 in 1 product and durability and optical properties are significantly improved.”

AkzoNobel is known for the development of non-chrome and chromate-free technologies, helping its customers reduce aircraft weight, improve fuel efficiency and reduce emissions without compromising on quality. The company is also going further.

“As the materials used to manufacture airplanes have evolved, from aluminum to lightweight advanced composite systems, so too must our coatings evolve,” said Swearingin. “As such, we are working closely with our OEM partners to develop the coatings of the future that are compatible with the substrates and processes of the future, and this is a very exciting place to be.”

“We are also investing more into the development of our film capabilities, which alongside our powder coatings and liquid paints enable us to protect and enhance every part of an airplane, from the structure to the cabin interior, for the parts you can see, and the parts you can’t. It’s part of our ‘One AkzoNobel’ philosophy, a philosophy that is helping us to further strengthen the partnerships we have with our customers to find creative and timely solutions and play our part in keeping the production lines rolling.”

“There will always be future opportunistic challenges ahead,” Swearingin added. “We welcome these challenges as a chance to build further resilience into the business. It is why we are investing for the long term, in new production capability, new products, and new ways of working. It is why we are exploring ways of qualifying secondary raw material providers, to make us even more robust and protect supplies with dual sourcing.

And it’s why we see the current supply challenges in the industry not as a threat, but rather a very great opportunity to become more self-sufficient, to become stronger in ourselves, and for our customers.”

“As the global leader in the development and supply of aerospace coatings, sealants and packaging, and the leading producer of topcoats and primers, PPG has a long history of proven technologies and unique products,” said Peffer. “We are always looking at ways to help our customers meet sustainability and performance goals, and some of the many newly commercialized in the past few years include:

• Qualified chrome free primers to replace chromated primers in the commercial, aftermarket and military markets. For example, PPG AEROCRON Electrocoat primer is a waterborne, chrome free technology that is applied electrically in a bath instead of traditional spray application methods. It has a transfer efficiency of >95%, compared to spray application of ~50% and is also lighter weight.

• PPG BOUNDLESS CA6500 Topcoat Series for the general aviation market is specifically tailored for light aircraft and helicopters. The series is composed of low VOC polyurethane coatings, which are designed to provide excellent durability, performance and appearance characteristics with minimal regulated VOC and volatile hazardous air pollutant (VoHAPS) emissions. The CA6500 series is available in topcoat, clear coat gloss, semi-gloss and flat ranges.

• The DESOTHANE basecoat/clearcoat system that has been applied to hundreds of aircraft globally in the aftermarket, as well as major OEMs. PPG Desothane HD basecoat/clearcoat consists of a pigment-rich basecoat that provides color with less paint than conventional coatings, saving material, weight and application time. The clearcoat extends service life, improves buffability and achieves a smoother, high-gloss surface that is easier to clean.

• A new solar heat management coating that helps when using darker colors to keep the aircraft up to 25% cooler, depending on color.

“Regarding product development, we see the most significant trend in sustainability. The most crucial factor here continues to be weight,” said Lang. “For example, modern and lightweight rigid foams are only made possible in the interior sector by coatings or production processes such as 3D printing. We have developed a filler, especially for this purpose, ALEXIT PrimeFill, which creates a perfectly even surface for a decor of the airline’s choice and adds the lowest possible weight. In addition, our customers appreciate that our products are primarily water-based and do not require oven drying.”

In the area of structural parts, the development focus continues to be on chromate-free corrosion protection systems. Promising results have been achieved here for certain applications.

“For us, the replacement of chromate-containing systems with at least equivalent performance has the highest development priority,” Lang said. “This is no easy task because chromates offer an extensive range of performance features behind which the lives and health of many passengers are at stake.” Furthermore, even more flexible systems are demanded and in development when it comes to coatings for composites.

Sustainability approaches also include the implementation of renewable raw materials, weight savings, long-term durability and new additional functionalities. “The goal remains to minimize the CO2 footprint in the entire supply chain and to pursue a cradle-to-cradle approach,” said Lang. In parallel, products are being developed that substitute traditional technologies outside the paint world with more sustainable and stable solutions in paint or even paint.

“In the exterior segment, we focus on special applications in our new developments. These can be special areas on the aircraft or functions such as particularly high flexibility in the primer area. The sustainability of coating systems, in general, comes very much from the fact that the substrates used often have a very long service life only because of the coating. In addition, many surfaces can be repaired economically with coatings. Furthermore, Mankiewicz has always set a very high standard for developing water-based coatings with low volatile organic content and lean application processes, setting standards far above the requirements. Also, for example, the possibility of avoiding oven drying or reducing the hangar temperature saves much energy.”

“The airline industry, aircraft OEMs and the aerospace coatings market are on a growth trajectory, but the challenges are not yet behind us, especially when it comes to the supply chain,” said Tami Swearingin, managing director for AkzoNobel Global Aerospace and Film. “Issues on a local and global scale, from the Texas freeze to the COVID-19 pandemic, have conspired to make a challenging time more difficult still. And with the ongoing conflict in Ukraine, the ability to be able to predict what happens next with any great certainty has been largely thrown out of the window.

“David Calhoun, the CEO at Boeing, expects supply chain issues within his business to continue to the end of 2023,” Swearingin noted. “Guillaume Faury, CEO of Airbus, also talks about the ‘depth and magnitude’ of recent crises as being particularly unusual, and admits to struggling with shortages of raw materials, electronic components and other parts. Airbus and Boeing are not alone. The leaders at Safran and Raytheon have also recently gone on record citing supply chain issues, and we can all, in this industry, share their pain. But we can also share their optimism and belief that our industry is on the road to recovery. Our best prediction at this time is to see a full recovery by 2024/2025.”

“The airline industry has recovered 90% from the pandemic levels in most parts of the world, with China lagging a little behind,” said Duane Utter, PPG OEM segment manager, aerospace coatings. PPG has seen a strong coatings market since early 2021. Demand continues to recover, leading to strong year-over-year organic sales growth of about 20% in Q4 2022, even though certain supply chain challenges remained.

According to Utter, airlines are well on their way to full recovery, but are still somewhat challenged with the staffing of crews, pilots and flight attendants, as well as ground crew and airport staff. These problems should resolve as the public continues to increase air travel, especially to foreign destinations. OAG (COVID-19 Airline Recovery | OAG) has tracked weekly air travel data during the last four years. This resource shows recent levels to be within 6 percent of 2019 pre-pandemic levels.

Mankiewicz Coatings is a global coatings manufacturer active in many industries. One is aviation, where they develop, produce and supply coatings for cabin interiors, exteriors and structural parts globally.

Last year, increasing business in the aviation industry that reached pre-pandemic levels could be observed. There were differences in the timing of this comeback, which started in the U.S., followed directly by Europe and Asia. Due to the tight corona rules in China, there were the biggest hold-ups, but the Chinese aviation industry is also experiencing strong growth.

The aviation supply chain, which has been severely cut back during COVID, is sometimes facing challenges in meeting this sudden spike in growth. “Through many measures, we have been able to retain the vital staff in all areas and so we are in the fortunate position of being ready for growth on our part,” said René Lang, executive managing director Aviation at Mankiewicz Coatings. “The business has become more global due to increased demand, though. Free maintenance slots are being used – no matter which end of the world they are available. Considering that we make individual bespoke suits in paint for our customers, it’s a big challenge to switch quickly and schedule the planned paint jobs in the U.S. now for China but through smart planning and clear communication, we are happy to make it happen again and again.”

Speaking about the supply chain, Mankiewicz is very proud to recently having received an SQIP Award from Airbus for its excellent performance in the “Materials and Parts” category. The award is presented annually to companies that have distinguished themselves through exceptional performance in the areas of product quality and delivery reliability. SQIP stands for “Supply Chain & Quality Improvement Program.” Mankiewicz has already received several awards from Airbus for outstanding delivery performance but this year they received the highest: the paint manufacturer was recognized as an “Accredited Supplier.” This award is only given if the supplier delivers supply chain excellence over more than two years.

Lang commented, “We are very thankful for our team and this special achievement. To maintain this top performance for several years in a row and not make any mistakes is something that makes me very proud and speaks for the high commitment of the Mankiewicz team. To supply products in this industry is already a high bar, and being among the best is terrific.”

Aerospace coatings consumers need to make sure the products they use deliver the highest performance.

“Commercial airlines are subjected to extremes of heat, cold, rain, lightning, sand, pressure, etc. – some of the harshest conditions imaginable,” said Swearingin. “Creating a single coating that protects everything is a challenge, but a coating system comprised of multiple components, each with a specific function, is possible, and can be very effective. Performance is primarily driven by the polymer network – the resins which keep the pigments together, providing overall cohesion of the paint film and adhesion to the substrate. They also give the coating its performance and durability. Formulating a coating that delivers at 40,000 feet or at Mach 0.86 is achieved through our in-house polymer synthesis capability to design and manufacture custom resins. We create a layer of multiple coatings, each with specific capabilities, that together act as multiple protective layers below the visible paint. The hardest working, toughest, and most technically advanced coatings are the ones that will never be seen by anyone but the applicator.”

“Thanks to strong, well-established relationships, and PPG’s coatings and sealants platform, our science and technology (S&T) teams are in constant contact with customers to better understand their evolving needs and the key drivers shaping the future of aviation, including productivity, efficiency and safety,” said Robin Peffer, PPG global product manager, aerospace coatings. “We leverage this feedback to evaluate our design profiles and formulations, to ensure that we’re delivering innovative products that protect and beautify – improving asset aesthetics while creating efficiencies, such as weight savings, and supporting compliance with future environmental, health and safety (EHS) regulations.”

Environmentally-preferred solutions are a top priority for PPG’s customers and its business. “We’ve sought to replace certain substances, such as chrome, with more eco-friendly alternatives, without sacrificing product performance,” said Peffer. “Furthermore, to better reach our customers and provide excellence service, PPG has a global network of 16 application support centers (ASCs). A 17th ASC will open in Toulouse, France, in the fourth quarter of 2023. Each ASC serves our customers on a regional level and is strategically located near aerospace hubs. The ASCs play a key role in supporting both large, commercial OEMs and aftermarket maintenance of aircraft by providing sealants, coatings, application equipment and repackaging of sealants and coatings for right-sized application.”

In aviation, the subject of weight continues to be at the core of requirements. “Every kg more means more kerosene consumption,” said Lang. “Kerosene is the most significant cost driver and CO2 emissions are directly related. This is therefore the biggest driver of sustainability and efficiency for airlines. In this context, as an example, coatings play a crucial role by replacing heavy with lightweight materials. Coatings can simulate metals or frosted glass, for example. Mankiewicz has an extensive portfolio of effect coatings that give the airline or manufacturer a free choice of combination in terms of color tone, effect, gloss level and touch effects. All coatings have one thing in common: they save weight and create opportunities for individualization and a feel-good factor in the air.”

“Paint users are grateful for the robustness of our systems,” Lang continued. “In interior, exterior and structural parts, it is essential to have large painting windows and to be able to use all possible painting methods. In addition, a repair capability is necessary for painting and flight operations. It is crucial that these are also well documented and trained and that paint solutions are available in small quantities in the right color and effect. Mankiewicz is very proud of its experienced global technical service crew, which optimizes painting processes on-site at the customer’s premises and makes painters fit for the job.”

As aerospace coatings products evolve, the frequency of the need to repaint has decreased.

Swearingin noted that external coatings have evolved rapidly in the last decade from single stage to basecoat/clearcoat systems, extending the need to repaint some aircraft for up to ten years or even more. Despite this, aircraft still tend to be taken out of service for maintenance every six or seven years without really knowing if a repaint is needed.

To address this issue AkzoNobel has launched Aerofleet Coatings Management, a new digital, data-driven service that helps airlines and other large operators to tailor and optimize the coatings’ replacement and maintenance schedule for individual aircraft within an airline fleet. It captures the data from both manual inspections and drone-operated inspections, creating a database of every aircraft in a fleet. The history includes details of the coatings used (e.g. single stage or basecoat/clearcoat coatings) along with flight path data (e.g. weather conditions etc.) which affect the integrity/longevity of the coating applied.

“By analyzing the captured information (e.g dry film thickness, color variation, gloss and general appearance), and mapping it over time, a more accurate maintenance and repaint schedule can be calculated and it becomes easier and more accurate to determine when an aircraft needs to be repainted, rather than simply using time or flight hours,” said Swearingin. “Schedules can be created that balance the practical performance of a coating and where the aircraft in a fleet are being operated (i.e. the different flight paths, distances, altitudes, environment etc.) against the aesthetic/marketing (i.e. branding) and business needs of the airline.”

“Often, planes are repainted whilst the coating still has life left in it,” Swearingin added. “Using our service will reduce costs while increasing aircraft availability by anything up to a year. Over time, the frequency with which aircraft need to be repainted will fall, which is significantly better for an airline’s bottom line, and better for the planet.”

Paint is a very important part of the aircraft. “While beautifying it and influencing the airline’s public image, it must protect for certain environmental and chemical conditions,” said Peffer. The primer used under the topcoat helps with corrosion and fluid resistance. Airlines typically repaint after approximately six to eight years, but that is being extended due to newer technology topcoats such as PPG’s DESOTHANE HD CA9007 and DESOTHANE HD 9008 basecoat/clearcoat systems.

Military aircraft are usually painted every four top six years, as the topcoat is designed for survivability. The primers feature the corrosion and fluid resistance seen on commercial aircraft, with additional IR reflectance to resist heat in extreme conditions.

Notably, PPG recently announced a collaboration with Aerobrand, a UK airline brand and design consultancy, to assist airlines customers with new coatings schemes and one-off special liveries. The new Livery Lab system will enable airlines to work closely with designers to create custom paint colors, give direct input on livery design, and manage all aspects of the livery change process.

According to Lang, typically an aircraft flies around for more than seven years with modern paint systems. “We monitored several aircraft that have been painted with our ALEXIT BaseCoat/ClearCoat paint system that have now been flying for more than ten years and some for even more than 13 years and still have a good gloss and their exterior skin is pretty intact. This is twice as long as required and usual. This is a significant achievement, as it saves the airline considerable money.”

In addition to the standard repaints after a certain period, livery changes/rebrandings, lease endings, and sales often require paint jobs out of sequence.

“We are very proud of the implemented rebrandings or the many airline start-ups and the corresponding livery consulting,” said Lang. “Here, our in-house designers and colorimetric experts work hand-in-hand with the customer to develop great ideas, which are reliably brought to life with the support of our experienced technicians.”

“Next to the minimum seven years that the exterior coating system on the fuselage must remain glossy, performant and durable, there are also the wings, which in the past often needed to be overhauled much sooner, as they suffered considerable gloss losses and repairs were always visible,” said Lang. “In contrast to the high-gloss BaseCoat/ClearCoat systems used on the fuselage, semi-gloss topcoats are traditionally used on the wings. The stresses are also different: the wings move a lot and hydraulic and de-icing fluids and kerosene also cause chemical stress. Challenging demands are placed on a coating system regarding flexibility, UV exposure and chemical resistance.”

Lang noted that in the past, this was solved with two different topcoats, a flexible one for the top side and a very chemical-resistant one for the bottom side. “Mankiewicz has designed a dedicated wing coat that for the first time, meets the requirements of both wing sides and is also repairable: ALEXIT WingFlex. More efficient processes can be realized with the 2 in 1 product and durability and optical properties are significantly improved.”

AkzoNobel is known for the development of non-chrome and chromate-free technologies, helping its customers reduce aircraft weight, improve fuel efficiency and reduce emissions without compromising on quality. The company is also going further.

“As the materials used to manufacture airplanes have evolved, from aluminum to lightweight advanced composite systems, so too must our coatings evolve,” said Swearingin. “As such, we are working closely with our OEM partners to develop the coatings of the future that are compatible with the substrates and processes of the future, and this is a very exciting place to be.”

“We are also investing more into the development of our film capabilities, which alongside our powder coatings and liquid paints enable us to protect and enhance every part of an airplane, from the structure to the cabin interior, for the parts you can see, and the parts you can’t. It’s part of our ‘One AkzoNobel’ philosophy, a philosophy that is helping us to further strengthen the partnerships we have with our customers to find creative and timely solutions and play our part in keeping the production lines rolling.”

“There will always be future opportunistic challenges ahead,” Swearingin added. “We welcome these challenges as a chance to build further resilience into the business. It is why we are investing for the long term, in new production capability, new products, and new ways of working. It is why we are exploring ways of qualifying secondary raw material providers, to make us even more robust and protect supplies with dual sourcing.

And it’s why we see the current supply challenges in the industry not as a threat, but rather a very great opportunity to become more self-sufficient, to become stronger in ourselves, and for our customers.”

“As the global leader in the development and supply of aerospace coatings, sealants and packaging, and the leading producer of topcoats and primers, PPG has a long history of proven technologies and unique products,” said Peffer. “We are always looking at ways to help our customers meet sustainability and performance goals, and some of the many newly commercialized in the past few years include:

• Qualified chrome free primers to replace chromated primers in the commercial, aftermarket and military markets. For example, PPG AEROCRON Electrocoat primer is a waterborne, chrome free technology that is applied electrically in a bath instead of traditional spray application methods. It has a transfer efficiency of >95%, compared to spray application of ~50% and is also lighter weight.

• PPG BOUNDLESS CA6500 Topcoat Series for the general aviation market is specifically tailored for light aircraft and helicopters. The series is composed of low VOC polyurethane coatings, which are designed to provide excellent durability, performance and appearance characteristics with minimal regulated VOC and volatile hazardous air pollutant (VoHAPS) emissions. The CA6500 series is available in topcoat, clear coat gloss, semi-gloss and flat ranges.

• The DESOTHANE basecoat/clearcoat system that has been applied to hundreds of aircraft globally in the aftermarket, as well as major OEMs. PPG Desothane HD basecoat/clearcoat consists of a pigment-rich basecoat that provides color with less paint than conventional coatings, saving material, weight and application time. The clearcoat extends service life, improves buffability and achieves a smoother, high-gloss surface that is easier to clean.

• A new solar heat management coating that helps when using darker colors to keep the aircraft up to 25% cooler, depending on color.

“Regarding product development, we see the most significant trend in sustainability. The most crucial factor here continues to be weight,” said Lang. “For example, modern and lightweight rigid foams are only made possible in the interior sector by coatings or production processes such as 3D printing. We have developed a filler, especially for this purpose, ALEXIT PrimeFill, which creates a perfectly even surface for a decor of the airline’s choice and adds the lowest possible weight. In addition, our customers appreciate that our products are primarily water-based and do not require oven drying.”

In the area of structural parts, the development focus continues to be on chromate-free corrosion protection systems. Promising results have been achieved here for certain applications.

“For us, the replacement of chromate-containing systems with at least equivalent performance has the highest development priority,” Lang said. “This is no easy task because chromates offer an extensive range of performance features behind which the lives and health of many passengers are at stake.” Furthermore, even more flexible systems are demanded and in development when it comes to coatings for composites.

Sustainability approaches also include the implementation of renewable raw materials, weight savings, long-term durability and new additional functionalities. “The goal remains to minimize the CO2 footprint in the entire supply chain and to pursue a cradle-to-cradle approach,” said Lang. In parallel, products are being developed that substitute traditional technologies outside the paint world with more sustainable and stable solutions in paint or even paint.

“In the exterior segment, we focus on special applications in our new developments. These can be special areas on the aircraft or functions such as particularly high flexibility in the primer area. The sustainability of coating systems, in general, comes very much from the fact that the substrates used often have a very long service life only because of the coating. In addition, many surfaces can be repaired economically with coatings. Furthermore, Mankiewicz has always set a very high standard for developing water-based coatings with low volatile organic content and lean application processes, setting standards far above the requirements. Also, for example, the possibility of avoiding oven drying or reducing the hangar temperature saves much energy.”