05.10.18

Coatings World recently had the opportunity to interview Andreas Ossenkopf, Director Head of Aviation at Mankiewicz on the state of the aerospace coatings market.

Coatings World: Did the aerospace coatings market experience growth in 2017?

Ossenkopf: The whole airline industry is experiencing growth at the moment, and the demand for coatings is expanding along with it.

The use of new materials like composites also calls for new coating solutions: as their surfaces are not as perfect as aluminum, fillers are needed. To meet this demand, we offer fillers to match every need and defect.

Another stimulus is the competition between airlines. Having a unique appearance is of ever-increasing importance, to differentiate from other carriers. The thing that catches the eye first and foremost when seeing an aircraft is its exterior paint and there is a trend for special liveries and the use of micas and vibrant colors.

The fact that paint can be used today where previously it was necessary to use decals also has a positive effect on the aerospace coatings market. The BaseCoat/ClearCoat system, originally developed by Mankiewicz in 2006, allows the use of paint to produce vivid colored liveries with the finest details. Its outstanding durability compared to decals, the excellent drying times of the BaseCoat and the paint’s special fading and blending properties make this coating a perfect match for the exacting demands of the aviation industry.

Coatings World: In addition to the reduction of weight, what other high-performance characteristics do your customers demand?

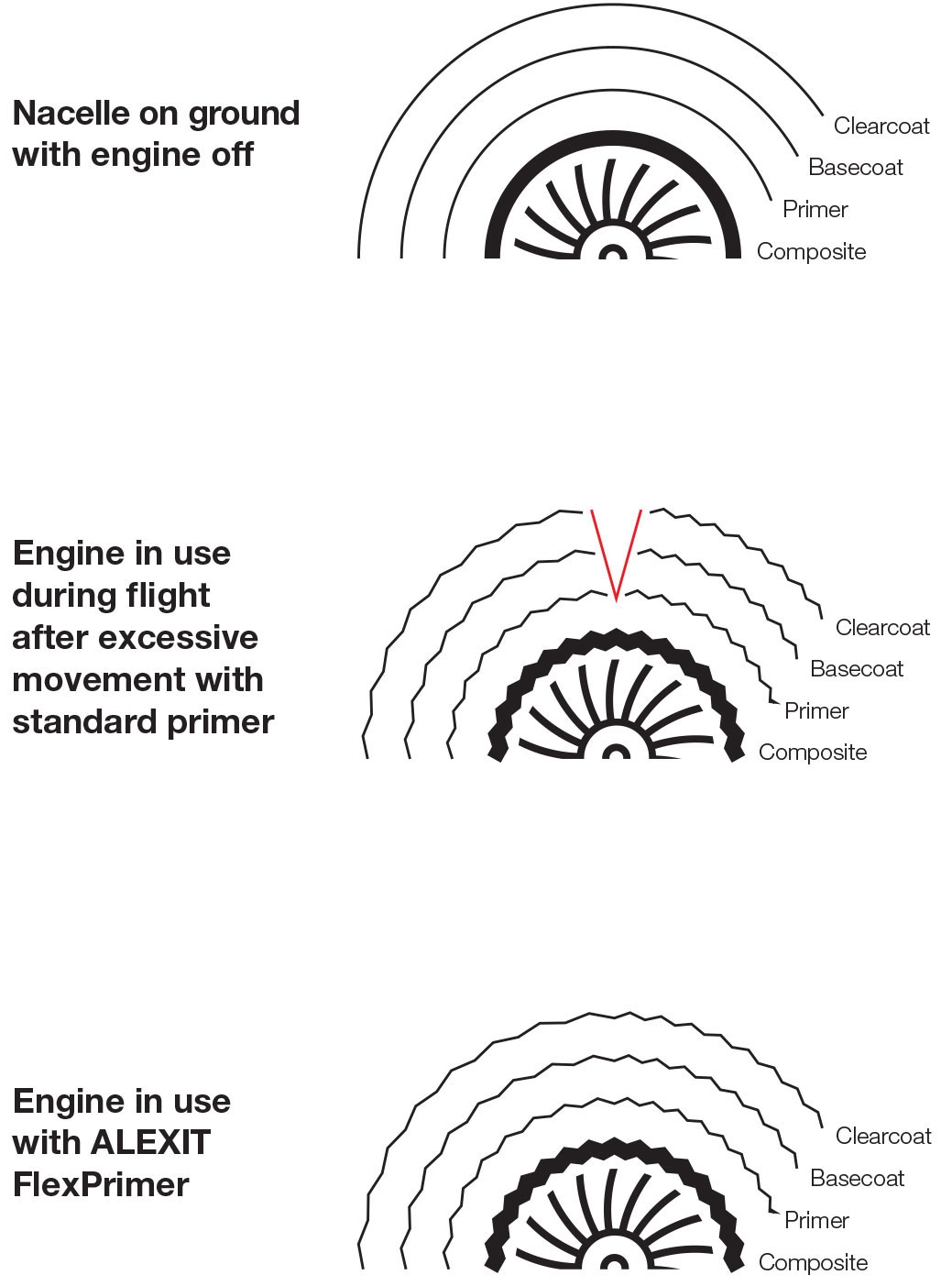

Ossenkopf: One very important demand is a coating solution for nacelles. The nacelles are the protectors of the heart and muscles of every aircraft, the engine. Their aim is to be aerodynamic and limit noise pollution, but most importantly to safeguard the engine. Special composite materials are used to reduce weight, provide acoustic protection and reinforce the structures they are part of.

Can you imagine the amount of stress a nacelle is exposed to? Stress not only comes from movements that the aircraft and in particular the wings make but also from strong vibrations that emanate from the engine. However, these are not the only stress factors for an engine nacelle – another is erosion. In addition, the composite materials used are much more flexible than aluminum. Finally, a nacelle has the task of image booster for the airline, because it is often the part of the livery that sports the airline’s logo.

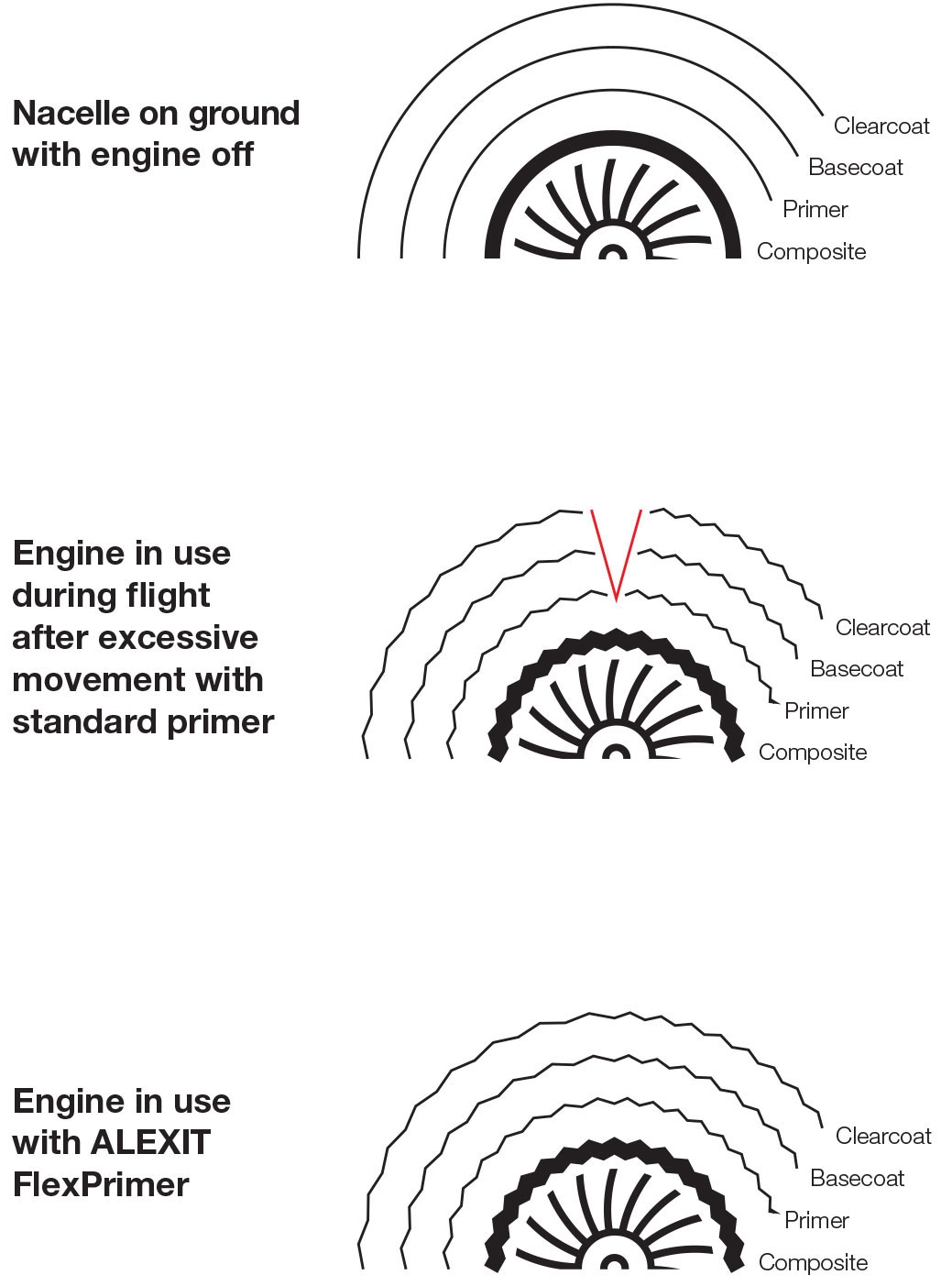

All this makes a nacelle’s requirements especially complex for the coating system used, and it must have a very high level of flexibility to permit all movements. The question is whether a standard exterior coating system, comprised of a primer and decorative paint system, can meet all these new requirements on flexible surfaces. In fact the ALEXIT TopCoat, BaseCoat and ClearCoat do have enough flexibility. A major vulnerability is that although most exterior primers are indeed flexible, the extreme movements and vibrations that the new composite materials can easily withstand will push all existing primers to their limits. That is why we developed a completely new primer to meet these requirements: The ALEXIT FlexPrimer 493-23.

Coatings World: How often does a plane need to be repainted/how often do companies change the livery?

Ossenkopf: Thanks to the long-lasting properties of the BaseCoat/ClearCoat system and the superb gloss finish of the ClearCoat, some aircraft painted with our coatings still look as good as new – even after nine years or more! But in general repainting cycles are much shorter than this.

Coatings World: What are the newest products your company has launched?

Ossenkopf: As mentioned earlier, Mankiewicz has developed and qualified a primer that is highly flexible and able to withstand the massive vibrations under which a flexible nacelle composite remains stable and intact: ALEXIT FlexPrimer 493-23.

Not only does the primer prevent the paint from cracking, but it also fulfills all properties of a normal exterior primer and is chromate-free. When used as a substitute for a regular primer, there is no need for a further layer and thus no additional weight is added. This way the engine nacelle stays looking good, there is no loss of availability caused by unplanned maintenance, and in general, fewer repairs are necessary.

Coatings World: In what areas are you focusing R&D efforts?

Ossenkopf: One of our latest R&D topics is, in fact, our FlexPrimer: The development in our R&D was subjected to theoretical testing as well as practical application on the nacelles of various customers as part of a monitoring program. The results convinced all who participated and solved a long-standing problem: Visible cracks would, of course, make passengers feel insecure. Without our FlexPrimer the airline had two possibilities: either they simply shrug it off or they shorten their maintenance cycles to repair the cracks regularly. However, sanding down and repainting composites is very time-consuming. By preventing the paint from cracking in the first place with our FlexPrimer, we found a solution that renders this problem for the airlines unnecessary.

Coatings World: Did the aerospace coatings market experience growth in 2017?

Ossenkopf: The whole airline industry is experiencing growth at the moment, and the demand for coatings is expanding along with it.

The use of new materials like composites also calls for new coating solutions: as their surfaces are not as perfect as aluminum, fillers are needed. To meet this demand, we offer fillers to match every need and defect.

Another stimulus is the competition between airlines. Having a unique appearance is of ever-increasing importance, to differentiate from other carriers. The thing that catches the eye first and foremost when seeing an aircraft is its exterior paint and there is a trend for special liveries and the use of micas and vibrant colors.

The fact that paint can be used today where previously it was necessary to use decals also has a positive effect on the aerospace coatings market. The BaseCoat/ClearCoat system, originally developed by Mankiewicz in 2006, allows the use of paint to produce vivid colored liveries with the finest details. Its outstanding durability compared to decals, the excellent drying times of the BaseCoat and the paint’s special fading and blending properties make this coating a perfect match for the exacting demands of the aviation industry.

Coatings World: In addition to the reduction of weight, what other high-performance characteristics do your customers demand?

Ossenkopf: One very important demand is a coating solution for nacelles. The nacelles are the protectors of the heart and muscles of every aircraft, the engine. Their aim is to be aerodynamic and limit noise pollution, but most importantly to safeguard the engine. Special composite materials are used to reduce weight, provide acoustic protection and reinforce the structures they are part of.

Can you imagine the amount of stress a nacelle is exposed to? Stress not only comes from movements that the aircraft and in particular the wings make but also from strong vibrations that emanate from the engine. However, these are not the only stress factors for an engine nacelle – another is erosion. In addition, the composite materials used are much more flexible than aluminum. Finally, a nacelle has the task of image booster for the airline, because it is often the part of the livery that sports the airline’s logo.

All this makes a nacelle’s requirements especially complex for the coating system used, and it must have a very high level of flexibility to permit all movements. The question is whether a standard exterior coating system, comprised of a primer and decorative paint system, can meet all these new requirements on flexible surfaces. In fact the ALEXIT TopCoat, BaseCoat and ClearCoat do have enough flexibility. A major vulnerability is that although most exterior primers are indeed flexible, the extreme movements and vibrations that the new composite materials can easily withstand will push all existing primers to their limits. That is why we developed a completely new primer to meet these requirements: The ALEXIT FlexPrimer 493-23.

Coatings World: How often does a plane need to be repainted/how often do companies change the livery?

Ossenkopf: Thanks to the long-lasting properties of the BaseCoat/ClearCoat system and the superb gloss finish of the ClearCoat, some aircraft painted with our coatings still look as good as new – even after nine years or more! But in general repainting cycles are much shorter than this.

Coatings World: What are the newest products your company has launched?

Ossenkopf: As mentioned earlier, Mankiewicz has developed and qualified a primer that is highly flexible and able to withstand the massive vibrations under which a flexible nacelle composite remains stable and intact: ALEXIT FlexPrimer 493-23.

Not only does the primer prevent the paint from cracking, but it also fulfills all properties of a normal exterior primer and is chromate-free. When used as a substitute for a regular primer, there is no need for a further layer and thus no additional weight is added. This way the engine nacelle stays looking good, there is no loss of availability caused by unplanned maintenance, and in general, fewer repairs are necessary.

Coatings World: In what areas are you focusing R&D efforts?

Ossenkopf: One of our latest R&D topics is, in fact, our FlexPrimer: The development in our R&D was subjected to theoretical testing as well as practical application on the nacelles of various customers as part of a monitoring program. The results convinced all who participated and solved a long-standing problem: Visible cracks would, of course, make passengers feel insecure. Without our FlexPrimer the airline had two possibilities: either they simply shrug it off or they shorten their maintenance cycles to repair the cracks regularly. However, sanding down and repainting composites is very time-consuming. By preventing the paint from cracking in the first place with our FlexPrimer, we found a solution that renders this problem for the airlines unnecessary.