Kerry Pianoforte, Editor02.01.23

Anue Water Technologies is a leading U.S. manufacturer of eco-friendly wastewater and odor control equipment for both municipal and industrial use, including chemical coatings and other manufacturing plants which are involved in the paint and coatings industry.

Anue offers two solutions – a Geomembrane Odor Control System and ChemFORSe technology – to combat odor in both municipal and industrial settings.

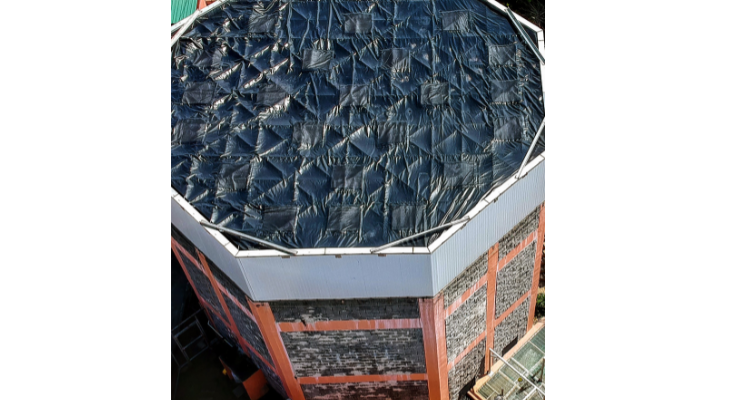

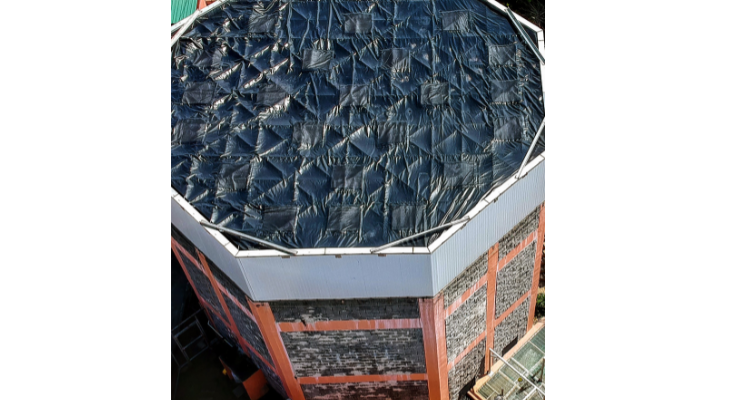

Anue’s Engineered Odor Control System technology is a patented, custom designed Geomembrane system with integrated carbon infused odor control filters to reduce odor emissions for almost any shape or size area, and is suitable for most climates. The covers are made of polyethylene and have velcro openings every square meter into which the carbon filters fit. The carbon filters, which eliminate the odors, can be replaced about once a year, depending on use.

“Our technology can be used anywhere from a single carbon filter to 30-40 filters based on a roof top filter house, said Greg Bock, Anue Water Technologies’ vice president and general manager. “We recently placed a 40 filter rooftop unit outside of Chicago at an animal processing facility and that application replaced a very large chemical masking application. It was a huge savings of chemicals spent converting to the carbon filter system.”

These flexible and easy to use membranes are supported by a cable grid and batten bars above the surface, making it unaffected by aeration, changing water levels, foaming and bacteria. This allows installation in some of the most challenging environments. The odor control systems require no power, are UV and chemical resistant and are chemical-free. The filter is engineered to allow gases and water to flow freely through the filters while they capture the odor causing contaminants.

The Engineered Odor Control System Series offers a one-year warranty against any manufacturing defects. The membrane has an expected lifetime of more than ten years, and the engineered specialty filter inserts last approximately 9-18 months depending on emissions levels.

ChemFORSe Odor Neutralizer equipment spreads a fine diluted chemical mist which reacts with and neutralizes odors. The ChemFORSe line of odor control chemistries and distribution equipment has been used to resolve both municipal and industrial airborne odor issues. The technology is environmentally friendly, meeting or exceeding all industrial, municipal, state and federal guidelines to date.

ChemFORSe works by counteracting malodorous odors through tag scent pairing using essential plant oil emulsion technologies.

ChemFORSe 7030SF is formulated to act as a year-round odor counteractant. ChemFORSe 7030SF is a water dispersible concentrate that can be diluted and run through line sprayers, dispersed through a vapor generation system, applied using a cold cannon fogger dispersal system or through direct application.

ChemFORSe 7030AC is formulated to act as an odor counteractant, ChemFORSe 7030AC is a water dispersible concentrate that contains activated charcoal for additional odor adsorption which can be applied through direct application only.

ChemFORSe Essential SF is formulated for moderate to heavy odor problems It is a natural essence designed for hot or cold vapor systems and is great for high dilution (5000:1) misting systems. This product is cold climate friendly, contains no Biocide and is biodegradable.

To complement the various ChemFORSe technologies, Anue offers a variety of foggers for humidification, misting - and chemical fogging needs.

“ChemFORSe technology was brought onboard due to a partnership with a supplier that has unique and patented odor neutralizing technology,” said Bock. “Trials have worked well in both municipal landfill and protein environments. The technology is transferable to the industrial market for fence line odor control.”

Anue has plans to make inroads into new markets. “Anue was initially focused on municipal water treatment and odor control. We are now expanding into industrial markets, such as food and beverage, paper manufacturing – any manufacturing facility that produces odor,” said Bock. “There are opportunities to utilize both the carbon filters – the primary go-to product because it is green, does not require water or chemistry and is bio-degradable and the ChemFORSe technology. We have plans to expand in the industrial world – textiles and paint and coatings plants.”

Anue offers two solutions – a Geomembrane Odor Control System and ChemFORSe technology – to combat odor in both municipal and industrial settings.

Engineered Odor Control Systems (EOCS)

Anue's Geomembrane System

Anue’s Engineered Odor Control System technology is a patented, custom designed Geomembrane system with integrated carbon infused odor control filters to reduce odor emissions for almost any shape or size area, and is suitable for most climates. The covers are made of polyethylene and have velcro openings every square meter into which the carbon filters fit. The carbon filters, which eliminate the odors, can be replaced about once a year, depending on use.

“Our technology can be used anywhere from a single carbon filter to 30-40 filters based on a roof top filter house, said Greg Bock, Anue Water Technologies’ vice president and general manager. “We recently placed a 40 filter rooftop unit outside of Chicago at an animal processing facility and that application replaced a very large chemical masking application. It was a huge savings of chemicals spent converting to the carbon filter system.”

These flexible and easy to use membranes are supported by a cable grid and batten bars above the surface, making it unaffected by aeration, changing water levels, foaming and bacteria. This allows installation in some of the most challenging environments. The odor control systems require no power, are UV and chemical resistant and are chemical-free. The filter is engineered to allow gases and water to flow freely through the filters while they capture the odor causing contaminants.

The Engineered Odor Control System Series offers a one-year warranty against any manufacturing defects. The membrane has an expected lifetime of more than ten years, and the engineered specialty filter inserts last approximately 9-18 months depending on emissions levels.

ChemFORSe Odor Neutralizers

ChemFORSe vapor system

ChemFORSe Odor Neutralizer equipment spreads a fine diluted chemical mist which reacts with and neutralizes odors. The ChemFORSe line of odor control chemistries and distribution equipment has been used to resolve both municipal and industrial airborne odor issues. The technology is environmentally friendly, meeting or exceeding all industrial, municipal, state and federal guidelines to date.

ChemFORSe works by counteracting malodorous odors through tag scent pairing using essential plant oil emulsion technologies.

ChemFORSe 7030SF is formulated to act as a year-round odor counteractant. ChemFORSe 7030SF is a water dispersible concentrate that can be diluted and run through line sprayers, dispersed through a vapor generation system, applied using a cold cannon fogger dispersal system or through direct application.

ChemFORSe 7030AC is formulated to act as an odor counteractant, ChemFORSe 7030AC is a water dispersible concentrate that contains activated charcoal for additional odor adsorption which can be applied through direct application only.

ChemFORSe Essential SF is formulated for moderate to heavy odor problems It is a natural essence designed for hot or cold vapor systems and is great for high dilution (5000:1) misting systems. This product is cold climate friendly, contains no Biocide and is biodegradable.

To complement the various ChemFORSe technologies, Anue offers a variety of foggers for humidification, misting - and chemical fogging needs.

“ChemFORSe technology was brought onboard due to a partnership with a supplier that has unique and patented odor neutralizing technology,” said Bock. “Trials have worked well in both municipal landfill and protein environments. The technology is transferable to the industrial market for fence line odor control.”

Anue has plans to make inroads into new markets. “Anue was initially focused on municipal water treatment and odor control. We are now expanding into industrial markets, such as food and beverage, paper manufacturing – any manufacturing facility that produces odor,” said Bock. “There are opportunities to utilize both the carbon filters – the primary go-to product because it is green, does not require water or chemistry and is bio-degradable and the ChemFORSe technology. We have plans to expand in the industrial world – textiles and paint and coatings plants.”