Greg Crom and Rob Culbertson, PPG Commercial Territory Managers 11.06.23

Machinery and equipment significantly contribute to farm business expenses. Larger machines, new technology, rising prices for parts and new machinery, and increasing energy prices have recently driven up machinery and power costs. Wear and corrosion remain the primary reasons for upgrading, substituting, and replacing this equipment and machinery.

Climate change has added a new layer of complexity to this challenge. As the world faces unpredictable weather patterns and increased exposure to harmful ultraviolet rays, the emphasis on protective coatings that can reflect these rays becomes even more pronounced. With these evolving threats, safeguarding the longevity and durability of farm equipment has never been more crucial.

How can the pervasive issue of rust be curtailed in the agricultural sector? The answer remains in powder coatings innovations, timely action, and robust collaborations with coating supplier partners.

Anti-rust measures are pivoting toward advanced powder coatings. In places like Iowa, a visible shift to powder coatings among heavy-duty equipment and agricultural manufacturers, from original equipment manufacturers to smaller fabricators, remains.

The appeal of powder coating stems from its efficiency, protective qualities, and speedy application that boosts productivity. For instance, PPG's ENVIROCRON Extreme Protection Edge augments the coating's adherence to equipment edges, ensuring longer-lasting protection. The layer sets new benchmarks, boasting 1,000 hours of salt spray resistance, effectively fending off premature rust.

An advanced coating, however, is only as good as its application process. That's where the partnership with a strong coatings supplier becomes critical. For example, PPG offers a holistic approach, from pre-treatment and cleaning to rigorous testing and on-site evaluations. The team collaborates with the clients from the outset, employing documentation and a disciplined approach to tailor-make coatings that consistently align with the client's color, manufacturing, and environmental specifications.

Greg Crom and Rob Culbertson are Commercial Territory Managers for PPG. Crom has 19 years of experience in the industry, while Culbertson has 12. Visit www.PPGVersolon.com to learn more.

Climate change has added a new layer of complexity to this challenge. As the world faces unpredictable weather patterns and increased exposure to harmful ultraviolet rays, the emphasis on protective coatings that can reflect these rays becomes even more pronounced. With these evolving threats, safeguarding the longevity and durability of farm equipment has never been more crucial.

How can the pervasive issue of rust be curtailed in the agricultural sector? The answer remains in powder coatings innovations, timely action, and robust collaborations with coating supplier partners.

The powder solution

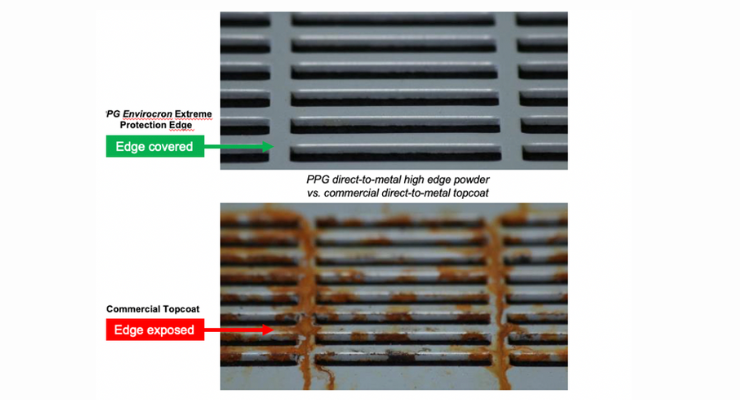

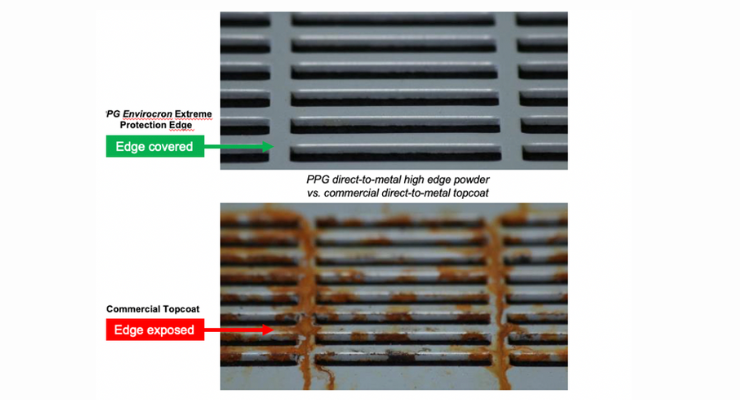

The edges of metal equipment are particularly susceptible to rust, mainly because conventional coatings often recede from these sharp points during application. This retreat leaves these sections less guarded, making them the primary candidates for rust.Anti-rust measures are pivoting toward advanced powder coatings. In places like Iowa, a visible shift to powder coatings among heavy-duty equipment and agricultural manufacturers, from original equipment manufacturers to smaller fabricators, remains.

The appeal of powder coating stems from its efficiency, protective qualities, and speedy application that boosts productivity. For instance, PPG's ENVIROCRON Extreme Protection Edge augments the coating's adherence to equipment edges, ensuring longer-lasting protection. The layer sets new benchmarks, boasting 1,000 hours of salt spray resistance, effectively fending off premature rust.

Conduct regular line surveys

Regular "line surveys" remain important. They refine processes and pre-empt potential issues that could disrupt manufacturing operations. Ongoing evaluations pave the way for energy efficiency, a reduced operational footprint, fewer warranty claims arising from edge corrosion, and savings on equipment. A recent collaboration with a U.S. trailer manufacturer exemplifies this, resulting in enhanced products and long-term cost efficiency. They transitioned to PPG's ENVIROCRON Extreme Protection Edge. The one-coat application boasts outstanding edge protection. The solution ensures prolonged field longevity, ultimately leading to sustained cost savings.An advanced coating, however, is only as good as its application process. That's where the partnership with a strong coatings supplier becomes critical. For example, PPG offers a holistic approach, from pre-treatment and cleaning to rigorous testing and on-site evaluations. The team collaborates with the clients from the outset, employing documentation and a disciplined approach to tailor-make coatings that consistently align with the client's color, manufacturing, and environmental specifications.

Ongoing technical support

The importance of continuous technical support from a strong coatings partner keeps operations steady. The right coatings supplier provides superior products and guides users through best practices and challenges. Rooted in rigorous research, development, and state-of-the-art lab facilities, the PPG team assures swift and effective resolutions with experts delivering in-house technical assistance and troubleshooting. Customers report the importance of their coating suppliers being more than a supplier but more of an extension of their business. They realize the importance of a business and technical coating supplier partner to ensure they efficiently put out the best product. They truly realize they receive much more than paint from their supplier. Routine line audits, application training for painters, and environment, health, and safety updates and training are just a few additional benefits a coating partner should provide.Looking ahead

The emphasis on pioneering coating solutions to extend equipment longevity becomes paramount as weather patterns grow unpredictable. It's evident that innovation, rooted in a solid partnership with coating suppliers, remains instrumental. But this goes beyond mere transactions. It's about genuinely comprehending challenges, enhancing efficiencies, and fostering lasting partnerships—all aimed at prolonging the life of farm equipment, boosting brand prestige, reducing warranty claims, enhancing resale value, and ensuring operational consistency.Greg Crom and Rob Culbertson are Commercial Territory Managers for PPG. Crom has 19 years of experience in the industry, while Culbertson has 12. Visit www.PPGVersolon.com to learn more.