11.17.17

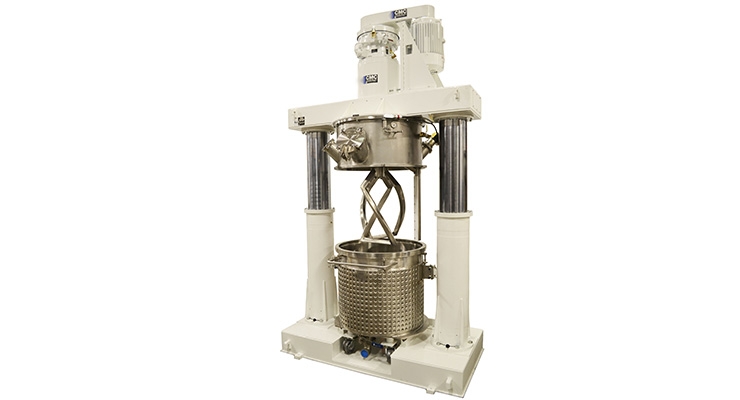

Custom Milling & Consulting, Inc. expands equipment line to include large volume production size double planetary mixers. As the demand for processing equipment that can handle high viscosity materials in large batch sizes continues to grow; CMC’s team of experts got together and engineered a whole new line of mixers and ram presses. The first of these machines to be completed is the DPM-700 explosion-proof, vacuum capable, all stainless double planetary mixer fitted with twisted gate blades.

CMC has been in the market of manufacturing high quality mixing, milling, and dispersion equipment for many years. The team of engineers took their current knowledge and expertise on manufacturing processing equipment and expanded on it. They used the same highly efficient close tolerance technology from the small mixers and applied it to the new large production size machines.

Every mixer is equipped with precision machined tanks, which allows for very close clearances between the blades, as well as the blades to the tank wall. The result is a high rate of shear that occurs as each blade rotates on its own access while orbiting around the tank. The combination of these close tolerances, and the coverage created by the orbiting of the rotating blades will quickly yield high quality mixes and dispersions.

To further enhance your production efficiency, CMC has designed a Ram Press with double seal technology. The platen on the ram press was engineered with a double o-ring seal that fits snuggly against the tank walls. This tight fit and smooth operating hydraulic cylinder ensure that you will experience minimal product waste due to product bypassing.

CMC’s DPM-700 is able to process batch sizes that range from 140 to over 600 Liters. It can be customized to include a variety of features from PLC controls, jacketed tanks, straight gate blades, side walls scarpers, vacuum capabilities and much more.

CMC has been in the market of manufacturing high quality mixing, milling, and dispersion equipment for many years. The team of engineers took their current knowledge and expertise on manufacturing processing equipment and expanded on it. They used the same highly efficient close tolerance technology from the small mixers and applied it to the new large production size machines.

Every mixer is equipped with precision machined tanks, which allows for very close clearances between the blades, as well as the blades to the tank wall. The result is a high rate of shear that occurs as each blade rotates on its own access while orbiting around the tank. The combination of these close tolerances, and the coverage created by the orbiting of the rotating blades will quickly yield high quality mixes and dispersions.

To further enhance your production efficiency, CMC has designed a Ram Press with double seal technology. The platen on the ram press was engineered with a double o-ring seal that fits snuggly against the tank walls. This tight fit and smooth operating hydraulic cylinder ensure that you will experience minimal product waste due to product bypassing.

CMC’s DPM-700 is able to process batch sizes that range from 140 to over 600 Liters. It can be customized to include a variety of features from PLC controls, jacketed tanks, straight gate blades, side walls scarpers, vacuum capabilities and much more.