T.S. McCracken, Covestro, Pittsburgh, PA 01.07.19

Abstract

The wood composite industry has been using PMDI since the 1970s, most notably in oriented strand board products. With current formaldehyde emission reduction initiatives, PMDI has been moving into the particle board and medium density fiberboard areas as well. The industry has been looking for a fast curing PMDI to compete with the catalyzed urea/melamine resins with the goal to reduce press times. When using PMDI for wood composites, the process comprises combining wood particles with a PMDI resin, followed by molding or compressing the coated combination of wood particles. PMDI prepolymers are useful as single component binders as they do not require separate catalyst or polyol streams to be metered into the resin at the mill facilities which would require additional personnel to monitor the process. The binders are advantageous in that they may be used to reduce press times without the addition of a catalyst, may be run with higher wood moisture contents, and provide longer shelf life (when stored properly) when compared to the other commonly known catalyzed wood binder systems. This paper looks at various single component PMDI’s reactivity and press time reduction results for laboratory produced panels. The data shows that the proper choice of prepolymer can allow for reduced press times for enhanced productivity and efficiency in panel production.

Introduction

Since the early 1980s, polymeric MDI has been used as a commercial wood binding adhesive in North America, primarily as a binder in oriented strand board (OSB) and engineered lumber.1 It has since gained acceptance as a Particleboard and Medium Density Fiberboard (MDF) wood binder in North America. Within the past 7 years, the biggest driver for PMDI in the Particleboard and MDF areas has been the regulation of formaldehyde emissions. Introduction of the California Air Resources Board (CARB) standard created an opportunity to convert more composite wood manufacturers from UF to PMDI. Reducing or eliminating formaldehyde in the composite panel area has become a priority for wood products manufacturers. As manufacturers looked for alternatives to UF resin, PMDI offered them a no-added-formaldehyde (NAF) alternative product.

PMDI offers manufacturers lower resin dosage, reduced wood drying requirements, lower VOC emissions, and higher out-of-press moisture content for better dimensional stability, excellent moisture resistance, and better physical properties. PMDI is known to have a high reactivity with moisture which is the driving force in the wood isocyanate reaction but its reactivity is, unfortunately, slower than UF resins. When manufacturers trialed PMDI they identified two problems.

• When running uncatalyzed PMDI resins, productivity for certain products dropped as slower cure times led to slower line speeds, especially when running the thinner products.

• Catalyzed PMDI resins often demonstrated pre-curing of the resin especially in the summertime in the southern USA. Pre-cure occurs when moisture and the resin react prior to the wood being pressed. This pre-cure issue often manifests itself by buildup on the forming rollers, clumping along the bin sidewalls and low board properties. Since a catalyzed system can be exposed to heat (100 to 130 °F) and moisture (humidity) in the forming bins or on the forming line, the potential for pre-curing exists. It will typically take 10 to 20 minutes to turn material over to the press and any delays (line stoppage) can increase the pre-cure potential.

With prolonged line stoppages, the resinated wood may have to be dumped which costs the manufacturer in resin and wood. As exposure to high heat and moisture is common in wood forming bins, it is important to have a resin system that is not as sensitive to these factors so it can operate with a wider processing latitude.

To increase the reactivity of PMDI, mill trials were performed by injecting catalysts inline and spraying catalyst/polyol on the wood fiber itself, but with limited success due to the inconsistency in board properties and material build-up within the production process. Some of these issues could be attributed to the short inline mix time and very small dosage amounts (catalyst distribution) or poor distribution of small catalytic quantities during the spray approach.

A more reliable way was needed to catalyze the wood – PMDI reaction and it should be a single component resin requiring no dosing equipment and have the same shelf life as our current 541 wood binder PMDI.

It was decided that it would be advantageous to provide an isocyanate binder that is water tolerant that may be used with wood fiber raw materials having moisture contents from about 10% and higher, allows shorter press times without requiring a third stream catalyst, reduces isocyanate press emissions during production and has a minimum 6-month shelf life.3 This paper documents the evaluation of multiple, single-component prepolymers for an improved cure without the potential for pre-cure, and which maintains acceptable shelf life stability for a wood binder.

Our purpose was to evaluate PMDI prepolymer reactivity and shorter pressing times. Internal bond properties were measured because it is the major indicator of resin strength in a panel board. Laboratory test boards were made with conventional particleboard furnish, by varying the type and polyol additive or amounts with PMDI. The data presented here is a small part of a much larger project that looks at the effects of other parameters on these resins such as mat moisture, wax content, wood species, bin life, and dimensional stability. We have been investigating modifications to our current PMDI wood binder to further enhance some of the above advantages. This paper illustrates a small part of the progress we have made in adapting PMDI to shorten press cycles while maintaining binder stability and shelf life for the hot pressing process.

Experimental

Time Temperature Reactivity

Time-temperature reactivity evaluations were used as the initial method of analysis. We used Covestro’s Vorschrift LE-PUHS-09-91 method which was designed specifically for evaluating PMDI as wood binders. The time-temperature technique has been evaluated internally against the DSC technique and has proven to be very comparable. The time-temperature procedure consists of blending PMDI resin with specified amounts of wax, water and emulsifier in a paper cup can which is then mixed for a specified time and then poured into a temperature conditioned container controlled at 100 °C. These conditions will force the reaction to completion and the exotherm is recorded. This method was found to be a quick and effective screening tool because two characteristics of the resulting graphs were of particular interest: the slope indicates the rate of reaction and shifts in curves indicate the induction time and temperature for the resin. Results from the time-temperature data enabled PMDI to be mixed with additives and quickly evaluated for curing characteristics.

Lab Panel Plan

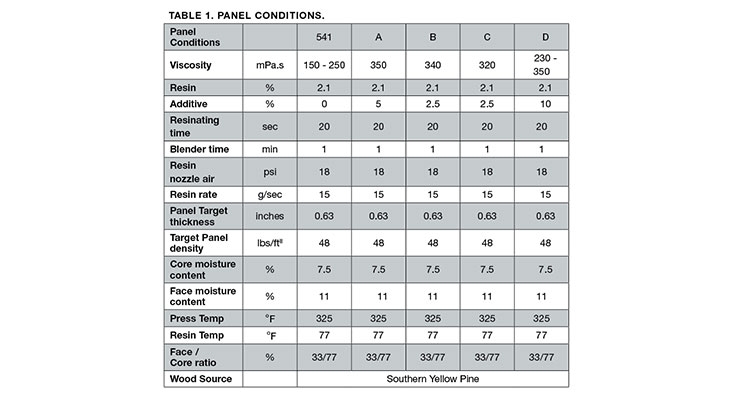

Panel conditions (Table 1) were chosen by using typical particle board mill target criteria.

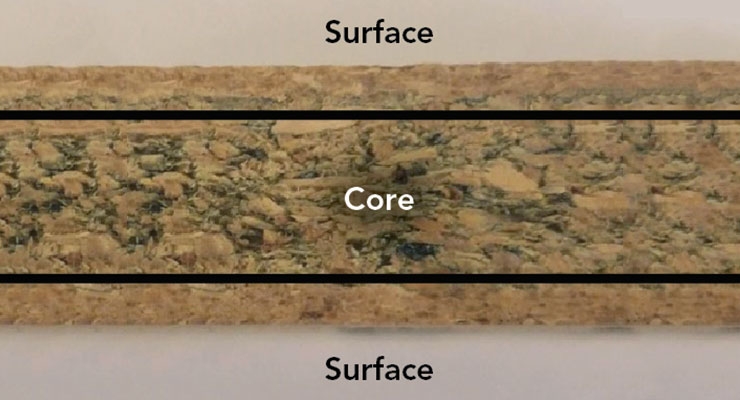

Southern Yellow Pine furnish was supplied by a southern U.S. particleboard mill. The wood was already screened for particle size to meet manufacturing standards for panel production. Three-layer laboratory boards were made from the supplied furnish (Figure 1).

Moisture content of the wood was adjusted by hot air drying and by water spray addition. Wood moisture content was adjusted to 11% in the face material and 7.5% in the core material. The material was then sealed in polyethylene bags for 24 hours to equilibrate. This was done so that any added moisture could penetrate into the wood rather than being topical. Covestro Mondur G-541 isocyanate was used as the control resin in the surface layers of the panel. This was to eliminate any possible pre-cure effect from the initial contact with the heated press platens. The prepolymer resins were used in the core of the board only. This was done because we did not know the potential of the prepolymer resins speed and did not want the heat of the initial platen contact to potentially pre-cure the surface material because this could lead to misinterpretation of internal bond testing results.

Panel Manufacture Procedure

Prepared material was weighed out to produce three panels per run. The face and core fiber were pre-weighed and then placed into a Lodige FM 130 Blender (Figure 2) to be resinated separately.

Figure 2. Lodige blender.

Face material was dosed with the 541 neat resin and the core material was dosed with the prepolymer modified Covestro Mondur G-541 resin. Resin percentage was applied on a dry wood basis. Resin was applied at 15 grams/sec through a vee-jet full cone nozzle at 18 psi while the material was being mixed in the blender. After the resin was added, the fiber was then blended for an additional 1 minute and then emptied into a large plastic container and then covered. Panels were then made using a 32.5 x 32.5 inch deckle forming box. The bottom steel caul plate was pretreated with 2.5 grams per square foot of release agent. The bottom surface material was then added to the box and spread-out evenly. The core material was then added and spread-out evenly. The top surface material was then added and spread- out evenly. The material was then pre-pressed using a 50 lb weight placed on top of the box to compress the panel. The panel surface was then sprayed with 2.5 grams per square foot of release agent and then placed into a 34 x 34 in hot press and then pressed to a final thickness of 5/8 inches at 325 °F for the specified press times. Each set of panels were made within a 30 minute time frame to minimize resin penetration and potential pre-cure issues. Panels were then trimmed to 26 x 26 inch to eliminate any potential edge effect for testing. Testing samples were then cut from all four sides of the panel and two strips down the middle. The samples were then lightly sanded to remove any possibility of release agent effect on sample testing. Samples were conditioned for 48 hours at 25 °C and 50% humidity and then the panel internal bonds were tested using ASTM method D1037-06a.6

Results and Discussion

Time and Temperature Reactivity

The underlying reasons for the excellent performance of PMDI resins continue to be researched, with significant effort devoted to detecting resin-wood covalent bonds. While spectral peaks consistent with urethanes have been detected via nuclear magnetic resonance spectroscopy, research has also suggested that common industrial manufacturing conditions lead to a chemically complex polyurea-based network.5 The proportion of polyurea, biuret/polyuret, allophanate and polyurethane bonds are strongly influenced by wood moisture, temperature, time and wood species and can all influence productivity and panel properties.4

It was hypothesized that a potentially effective additive would have a lower onset temperature and a fast reaction rate to create bonds more quickly. A material with a low onset temperature would help because the cure is partially limited by the heat flow through the wood. Wood is a good insulator, and the core of the board takes a longer time to heat up. If the additive can lower the onset temperature that is necessary for bond formation, the board may cure faster.

The resin reaction rate is also thought to be predictive of faster processing speed because it could lower the amount of time needed for the resin to form a strong bond network. Finally, the reaction rate would be indicative of an exothermic reaction and could be related to potentially reducing cure time since time and temperature are key elements when evaluating reactivity.

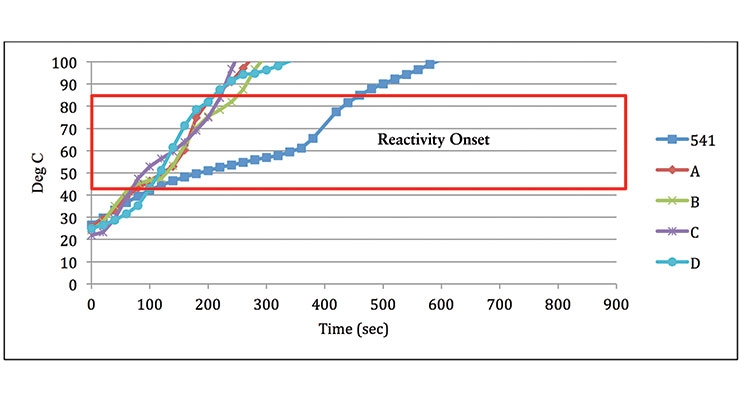

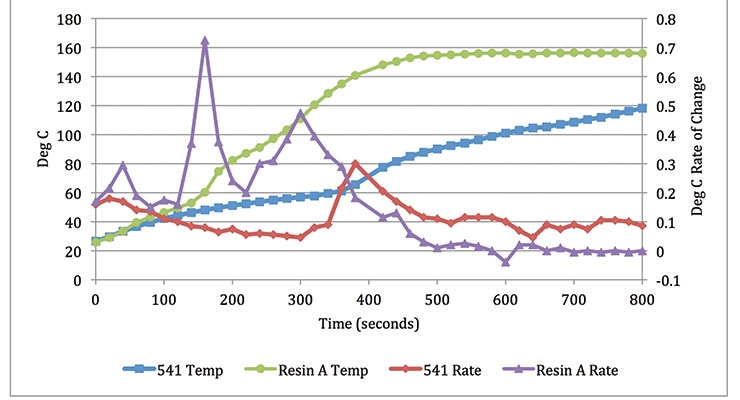

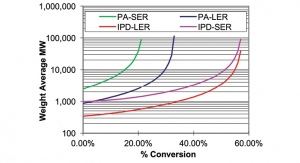

There are two parameters of interest that we look for when performing time temperature measurements. We look for temperature rise and rate of temperature change. When graphing these two parameters, we first look at the reactivity onset zone which typically occurs between 40 to 80 °C (Figure 3). This is where the material is beginning to heat up and we begin to look for early signs of a fast temperature rise which can be an indication of faster reactivity. One can see that the temperature rise of the 541 control resin is slower than the prepolymers.

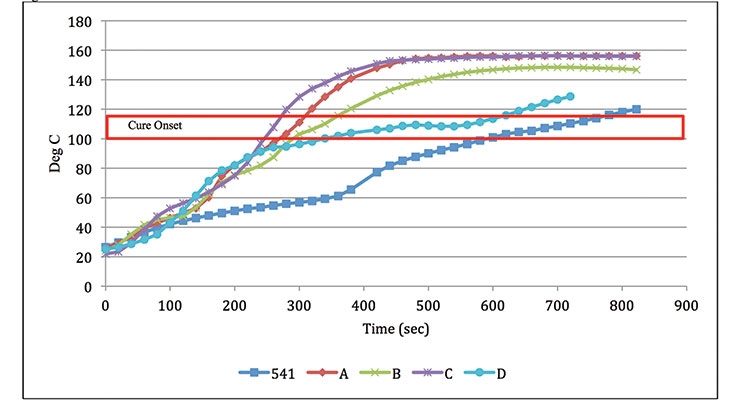

The second area that we look at is the cure onset zone (Figure 4). We know that PMDI typically cures at 105 °C.2 When we look at the cure onset temperature, we look at the time it takes to reach 100 to 110 °C (other dynamics within the pressing such as density, moisture content and wood species can swing these temperatures plus or minus 5 degrees).

Once the material reaches its cure temperature, the temperature will continue to climb slowly until it reaches its maximum exotherm as seen with the 541. The prepolymer PMDI’s show that there is still some exothermic reactivity happening after 110 °C because the temperature continues to rise at a steeper rate and they reach a much higher max temperature than the control. This indicates a stronger exothermic reaction and potential for a more efficient bond formation.

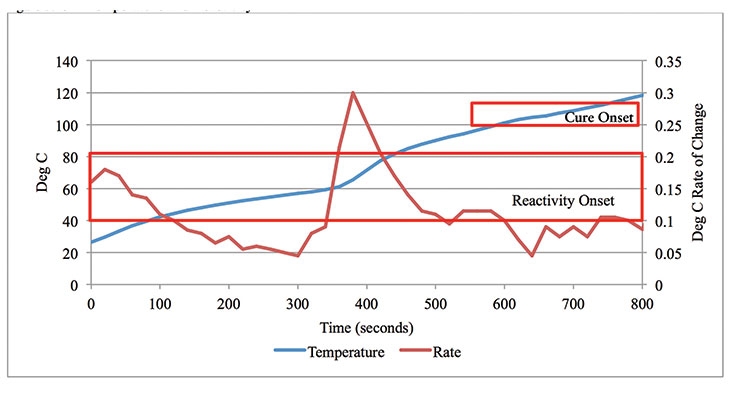

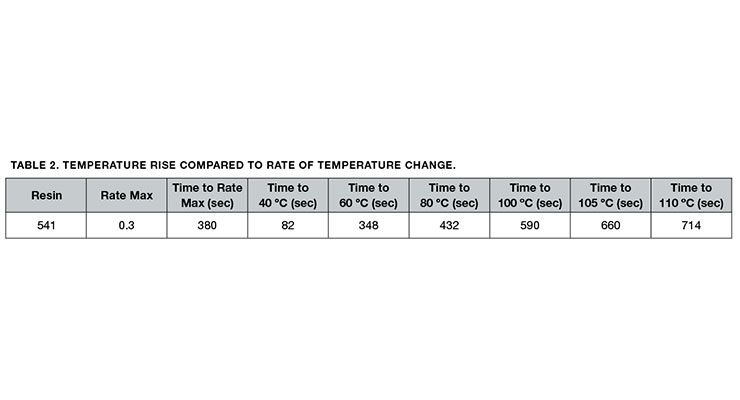

The other parameter we look for is the reactivity rate of the material. Figure 5 shows a typical reactivity control curve for 541 control PMDI. There are typically two distinct peaks that occur.

The first is at the beginning, as the material begins to heat. This occurs when the material is first exposed to heat until it reaches roughly 40 °C and then begins to slow down. By comparing the temperature rise to the rate of temperature change (Table 2), one can see that the changes are relatively slow until it hits 60 °C at which point the reactivity begins to increase. There is increased reactivity until it reaches 80 °C and once again begins to slow down. This is indicative of the formation of the urea bond which is relatively slow unless pushed with heat.

Once the resin hits 100 – 110 °C we can see a small reactivity peak and then a decrease in reactivity. It is at this point the resin is considered cured.

541 vs. Prepolymer

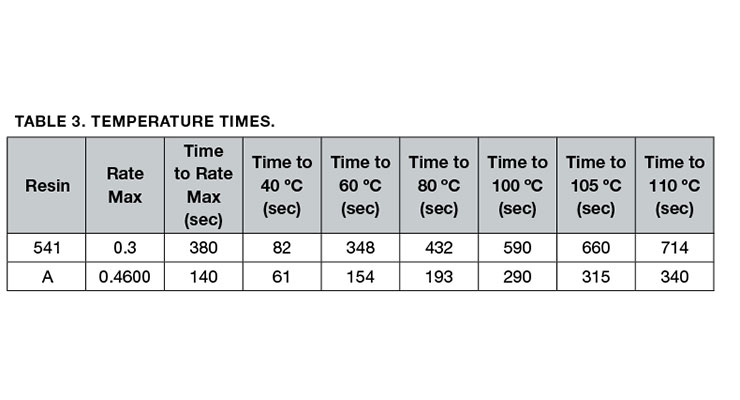

In Figure 6, a comparison can be seen between the control 541 and a prepolymer PMDI. The prepolymer shows an early but slightly faster temperature increase and the reactivity rate shows three distinct peaks of reactivity, whereas the control shows one small peak and one main peak. The first peak at 40 °C for the prepolymer indicates a higher reactivity than the control and could point to a potential resin pre-cure. The second peak or the pre-polymer has the largest rate increase from 50 to 80 °C and is clearly reacting faster than the control 541. A third peak happens within the cure onset zone as the temperature rises faster to a peak temperature of 156 °C vs 120 °C for the 541 peak temperature. This is indicating an increased exothermic reaction which can help drive the core temperature of the panel up faster than the control resin. In Table 3, temperature times and reactivity rate can be seen with the pre-polymer clearly reacting faster than the control 541.

Reactivity Rate Comparison

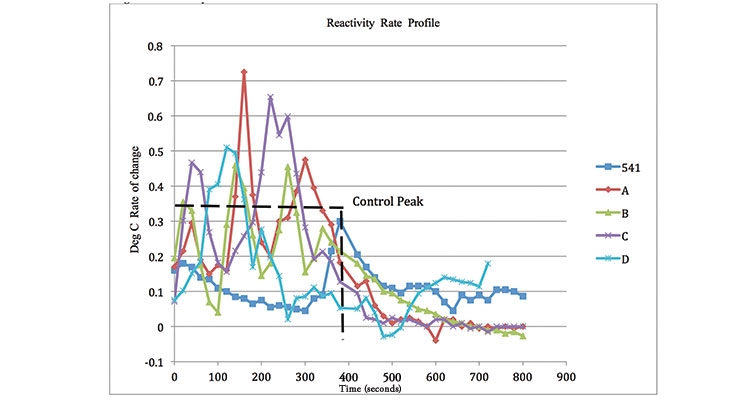

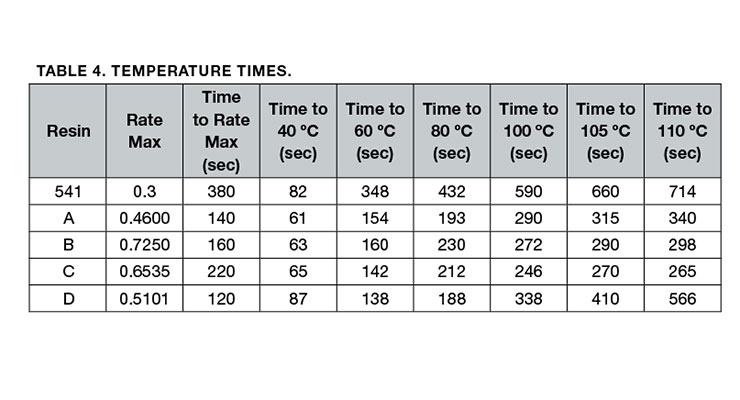

In Figure 7, all the prepolymer resins clearly show an increased reactivity with at least two to three distinctive peaks with all of them occurring before the control resins peak reaction rate. Resins A and B show three peaks with each having a different maximum reactivity rate. Resins C and D both have high initial rate peaks and may indicate potential for pre-cure, but have elongated secondary peaks that indicates a higher reactivity. Resins A and B both have the same three peaks but at different rates. This is mainly because resins A and B both have the same additive but at different percentages, with resin A being the higher. In Table 4, resins A, B and C clearly show they react faster and reach 100 °C before the other resins.

So what do these rates tell us? Samples A, B, C and D are somewhat similar in reaction other than the three reaction peaks that samples A and B exhibit. All four prepolymers appear to have similar reactivity times. As the samples reach cure temperatures (100 – 110 °C), samples B and C look to be the most reactive with the fastest overall times. It confirms that all of the prepolymers have higher maximum rate increases, faster times to reach 80°C and much shorter times to reach the curing temperatures than the 541 control. From the results in Table 4, we can now get a feel for the material's rate of reactivity and develop a panel pressing program to evaluate the resin speed in an actual press environment.

Lab Panel Results

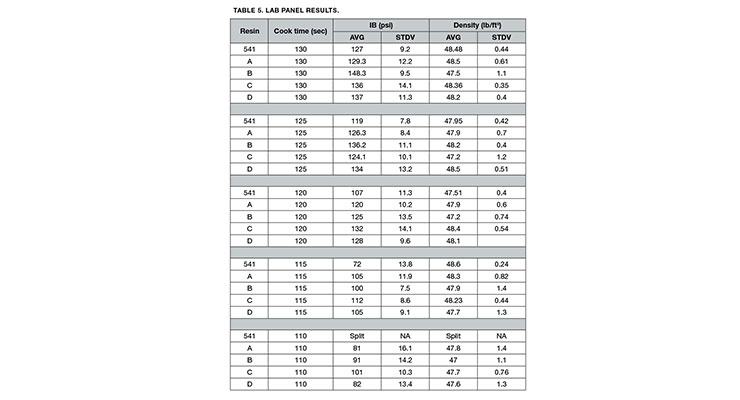

With temperature and reactivity data available, we then took our evaluation to the next step, which involved impregnating and pressing particleboard panels. We then began to evaluate press cook times. Cook time can be defined as the time it takes to cure a panel once it reaches target thickness until the press is ready to open to the de-gas stage. A base cook time of 130 seconds was used as a control time. This is the standard for PMDI for most particle board mills at the given thickness. In Table 5, we compare the various press times with the internal bond strength of the panels. At the control 130 second time, all of the IB’s (internal bond) are high and far exceed the 100 psi internal bond target which is to be expected. As we lower the time by five seconds, slight decreases can be seen in IB but not enough to be alarmed. One could even lower the cook time to 125 second and the properties would not change much.

As we lower the cook time by another 5 seconds and go to 120 seconds we begin to see differences. The internal bond strength begins to drop, particularly for the control, but it is still in the control range. We know from the reactivity profiles that the 541 is the slowest reacting, so when we open the press earlier, the resin bonds are not as fully formed and the internal bond strength will decrease. As we continue to decrease the press time to 115 seconds, we now see that the control 541 internal bond strength has dropped below the 100 psi target range and would fail. In a mill setting, correcting this issue would either add more press time (lower productivity) or increase the resin content (less efficient/economical). All of the other resins continue to meet the spec of 100 psi. With the next step down in press time to 110 seconds, this is where the strong (bond) shall survive. The 541 control did not hold together at all and split at the press opening. This is caused from poor bond formation with the panel and the internal gas pressure of the panel exceeding the bond strength. Resins A, B and D did not meet the 100 psi target but still had decent bond strength. Only resin C met the 100 psi internal bond target which was expected as it also had the fastest reactivity times.

Conclusion

Results from the pilot run demonstrated that the particle boards made with the prepolymer PMDI resin had better properties and at lower press times than the control. This confirms that we have lowered the reaction onset temperature and the panel internal bond results indicate that the prepolymer PMDI has potentially increased the efficiency of the bonding as indicated by the internal bond strength and reduced press times. The resins are also storage stable for 6 months (when stored under recommended storage conditions). The material requires no mill dosing equipment, is easy to handle (stable) with no apparent pre-curing of the resonated wood. We are currently continuing the study by performing long-term durability studies, analyzing the effects of moisture contents, of wood species and optimizing process parameters for optimal mill production.

References

1. R.N Hunt, J.W Rosthauser, W.S. Gustavich, K.W. Haider “ MOISTURE-CURING POLYMERIC- CURING WOOD BINDERS” presented at The Forest Products Society in Merida, Mexico June 1998.

2. J.W. Frink, H.D Layton “CURING PROFILE OF POLYMERIC MDI IN HARDWOOD FLAKEBOARD BONDING SYSTEMS”, Presented at the SPI 28th Technical /Marketing Conference.

3. U.S. Patent 6022444 Bayer Corporation, “MODIFIED PMDI FOR FASTER PRESS TIMES OR LOWER PRESS TEMPERATURES OF MDI FROM HOT PRESSES”.

4. T.M.Gruver , N.R. Brown, J.S Cionni, T.S.McCracken, W.J Nicola , T.Takah 2007, EFFECT OF SELECTED WOOD SPECIES AND MOISTURE CONTENT AND MOISTURE CONTENT ON PMDI RESIN APPLICATION AND PANEL PROPERTIES”. Wood and Fiber Science, April 2008, V. 40(2).

5. D.A. Redlinger, Naajian Sun, Charles E. Frazier, Tg AN INDEX OF CONVERSION IN PMDI- IMPGREGNATED WOOD, NCSU.EDU. Bioresources, Oct. 17, 2007.

6. ASTM (2006) Method D 1037-06a. AMERICAN SOCIETY FOR TESTING AND MATERIALS.

The wood composite industry has been using PMDI since the 1970s, most notably in oriented strand board products. With current formaldehyde emission reduction initiatives, PMDI has been moving into the particle board and medium density fiberboard areas as well. The industry has been looking for a fast curing PMDI to compete with the catalyzed urea/melamine resins with the goal to reduce press times. When using PMDI for wood composites, the process comprises combining wood particles with a PMDI resin, followed by molding or compressing the coated combination of wood particles. PMDI prepolymers are useful as single component binders as they do not require separate catalyst or polyol streams to be metered into the resin at the mill facilities which would require additional personnel to monitor the process. The binders are advantageous in that they may be used to reduce press times without the addition of a catalyst, may be run with higher wood moisture contents, and provide longer shelf life (when stored properly) when compared to the other commonly known catalyzed wood binder systems. This paper looks at various single component PMDI’s reactivity and press time reduction results for laboratory produced panels. The data shows that the proper choice of prepolymer can allow for reduced press times for enhanced productivity and efficiency in panel production.

Introduction

Since the early 1980s, polymeric MDI has been used as a commercial wood binding adhesive in North America, primarily as a binder in oriented strand board (OSB) and engineered lumber.1 It has since gained acceptance as a Particleboard and Medium Density Fiberboard (MDF) wood binder in North America. Within the past 7 years, the biggest driver for PMDI in the Particleboard and MDF areas has been the regulation of formaldehyde emissions. Introduction of the California Air Resources Board (CARB) standard created an opportunity to convert more composite wood manufacturers from UF to PMDI. Reducing or eliminating formaldehyde in the composite panel area has become a priority for wood products manufacturers. As manufacturers looked for alternatives to UF resin, PMDI offered them a no-added-formaldehyde (NAF) alternative product.

PMDI offers manufacturers lower resin dosage, reduced wood drying requirements, lower VOC emissions, and higher out-of-press moisture content for better dimensional stability, excellent moisture resistance, and better physical properties. PMDI is known to have a high reactivity with moisture which is the driving force in the wood isocyanate reaction but its reactivity is, unfortunately, slower than UF resins. When manufacturers trialed PMDI they identified two problems.

• When running uncatalyzed PMDI resins, productivity for certain products dropped as slower cure times led to slower line speeds, especially when running the thinner products.

• Catalyzed PMDI resins often demonstrated pre-curing of the resin especially in the summertime in the southern USA. Pre-cure occurs when moisture and the resin react prior to the wood being pressed. This pre-cure issue often manifests itself by buildup on the forming rollers, clumping along the bin sidewalls and low board properties. Since a catalyzed system can be exposed to heat (100 to 130 °F) and moisture (humidity) in the forming bins or on the forming line, the potential for pre-curing exists. It will typically take 10 to 20 minutes to turn material over to the press and any delays (line stoppage) can increase the pre-cure potential.

With prolonged line stoppages, the resinated wood may have to be dumped which costs the manufacturer in resin and wood. As exposure to high heat and moisture is common in wood forming bins, it is important to have a resin system that is not as sensitive to these factors so it can operate with a wider processing latitude.

To increase the reactivity of PMDI, mill trials were performed by injecting catalysts inline and spraying catalyst/polyol on the wood fiber itself, but with limited success due to the inconsistency in board properties and material build-up within the production process. Some of these issues could be attributed to the short inline mix time and very small dosage amounts (catalyst distribution) or poor distribution of small catalytic quantities during the spray approach.

A more reliable way was needed to catalyze the wood – PMDI reaction and it should be a single component resin requiring no dosing equipment and have the same shelf life as our current 541 wood binder PMDI.

It was decided that it would be advantageous to provide an isocyanate binder that is water tolerant that may be used with wood fiber raw materials having moisture contents from about 10% and higher, allows shorter press times without requiring a third stream catalyst, reduces isocyanate press emissions during production and has a minimum 6-month shelf life.3 This paper documents the evaluation of multiple, single-component prepolymers for an improved cure without the potential for pre-cure, and which maintains acceptable shelf life stability for a wood binder.

Our purpose was to evaluate PMDI prepolymer reactivity and shorter pressing times. Internal bond properties were measured because it is the major indicator of resin strength in a panel board. Laboratory test boards were made with conventional particleboard furnish, by varying the type and polyol additive or amounts with PMDI. The data presented here is a small part of a much larger project that looks at the effects of other parameters on these resins such as mat moisture, wax content, wood species, bin life, and dimensional stability. We have been investigating modifications to our current PMDI wood binder to further enhance some of the above advantages. This paper illustrates a small part of the progress we have made in adapting PMDI to shorten press cycles while maintaining binder stability and shelf life for the hot pressing process.

Experimental

Time Temperature Reactivity

Time-temperature reactivity evaluations were used as the initial method of analysis. We used Covestro’s Vorschrift LE-PUHS-09-91 method which was designed specifically for evaluating PMDI as wood binders. The time-temperature technique has been evaluated internally against the DSC technique and has proven to be very comparable. The time-temperature procedure consists of blending PMDI resin with specified amounts of wax, water and emulsifier in a paper cup can which is then mixed for a specified time and then poured into a temperature conditioned container controlled at 100 °C. These conditions will force the reaction to completion and the exotherm is recorded. This method was found to be a quick and effective screening tool because two characteristics of the resulting graphs were of particular interest: the slope indicates the rate of reaction and shifts in curves indicate the induction time and temperature for the resin. Results from the time-temperature data enabled PMDI to be mixed with additives and quickly evaluated for curing characteristics.

Lab Panel Plan

Panel conditions (Table 1) were chosen by using typical particle board mill target criteria.

Southern Yellow Pine furnish was supplied by a southern U.S. particleboard mill. The wood was already screened for particle size to meet manufacturing standards for panel production. Three-layer laboratory boards were made from the supplied furnish (Figure 1).

Moisture content of the wood was adjusted by hot air drying and by water spray addition. Wood moisture content was adjusted to 11% in the face material and 7.5% in the core material. The material was then sealed in polyethylene bags for 24 hours to equilibrate. This was done so that any added moisture could penetrate into the wood rather than being topical. Covestro Mondur G-541 isocyanate was used as the control resin in the surface layers of the panel. This was to eliminate any possible pre-cure effect from the initial contact with the heated press platens. The prepolymer resins were used in the core of the board only. This was done because we did not know the potential of the prepolymer resins speed and did not want the heat of the initial platen contact to potentially pre-cure the surface material because this could lead to misinterpretation of internal bond testing results.

Panel Manufacture Procedure

Prepared material was weighed out to produce three panels per run. The face and core fiber were pre-weighed and then placed into a Lodige FM 130 Blender (Figure 2) to be resinated separately.

Figure 2. Lodige blender.

Face material was dosed with the 541 neat resin and the core material was dosed with the prepolymer modified Covestro Mondur G-541 resin. Resin percentage was applied on a dry wood basis. Resin was applied at 15 grams/sec through a vee-jet full cone nozzle at 18 psi while the material was being mixed in the blender. After the resin was added, the fiber was then blended for an additional 1 minute and then emptied into a large plastic container and then covered. Panels were then made using a 32.5 x 32.5 inch deckle forming box. The bottom steel caul plate was pretreated with 2.5 grams per square foot of release agent. The bottom surface material was then added to the box and spread-out evenly. The core material was then added and spread-out evenly. The top surface material was then added and spread- out evenly. The material was then pre-pressed using a 50 lb weight placed on top of the box to compress the panel. The panel surface was then sprayed with 2.5 grams per square foot of release agent and then placed into a 34 x 34 in hot press and then pressed to a final thickness of 5/8 inches at 325 °F for the specified press times. Each set of panels were made within a 30 minute time frame to minimize resin penetration and potential pre-cure issues. Panels were then trimmed to 26 x 26 inch to eliminate any potential edge effect for testing. Testing samples were then cut from all four sides of the panel and two strips down the middle. The samples were then lightly sanded to remove any possibility of release agent effect on sample testing. Samples were conditioned for 48 hours at 25 °C and 50% humidity and then the panel internal bonds were tested using ASTM method D1037-06a.6

Results and Discussion

Time and Temperature Reactivity

The underlying reasons for the excellent performance of PMDI resins continue to be researched, with significant effort devoted to detecting resin-wood covalent bonds. While spectral peaks consistent with urethanes have been detected via nuclear magnetic resonance spectroscopy, research has also suggested that common industrial manufacturing conditions lead to a chemically complex polyurea-based network.5 The proportion of polyurea, biuret/polyuret, allophanate and polyurethane bonds are strongly influenced by wood moisture, temperature, time and wood species and can all influence productivity and panel properties.4

It was hypothesized that a potentially effective additive would have a lower onset temperature and a fast reaction rate to create bonds more quickly. A material with a low onset temperature would help because the cure is partially limited by the heat flow through the wood. Wood is a good insulator, and the core of the board takes a longer time to heat up. If the additive can lower the onset temperature that is necessary for bond formation, the board may cure faster.

The resin reaction rate is also thought to be predictive of faster processing speed because it could lower the amount of time needed for the resin to form a strong bond network. Finally, the reaction rate would be indicative of an exothermic reaction and could be related to potentially reducing cure time since time and temperature are key elements when evaluating reactivity.

There are two parameters of interest that we look for when performing time temperature measurements. We look for temperature rise and rate of temperature change. When graphing these two parameters, we first look at the reactivity onset zone which typically occurs between 40 to 80 °C (Figure 3). This is where the material is beginning to heat up and we begin to look for early signs of a fast temperature rise which can be an indication of faster reactivity. One can see that the temperature rise of the 541 control resin is slower than the prepolymers.

The second area that we look at is the cure onset zone (Figure 4). We know that PMDI typically cures at 105 °C.2 When we look at the cure onset temperature, we look at the time it takes to reach 100 to 110 °C (other dynamics within the pressing such as density, moisture content and wood species can swing these temperatures plus or minus 5 degrees).

Once the material reaches its cure temperature, the temperature will continue to climb slowly until it reaches its maximum exotherm as seen with the 541. The prepolymer PMDI’s show that there is still some exothermic reactivity happening after 110 °C because the temperature continues to rise at a steeper rate and they reach a much higher max temperature than the control. This indicates a stronger exothermic reaction and potential for a more efficient bond formation.

The other parameter we look for is the reactivity rate of the material. Figure 5 shows a typical reactivity control curve for 541 control PMDI. There are typically two distinct peaks that occur.

The first is at the beginning, as the material begins to heat. This occurs when the material is first exposed to heat until it reaches roughly 40 °C and then begins to slow down. By comparing the temperature rise to the rate of temperature change (Table 2), one can see that the changes are relatively slow until it hits 60 °C at which point the reactivity begins to increase. There is increased reactivity until it reaches 80 °C and once again begins to slow down. This is indicative of the formation of the urea bond which is relatively slow unless pushed with heat.

Once the resin hits 100 – 110 °C we can see a small reactivity peak and then a decrease in reactivity. It is at this point the resin is considered cured.

541 vs. Prepolymer

In Figure 6, a comparison can be seen between the control 541 and a prepolymer PMDI. The prepolymer shows an early but slightly faster temperature increase and the reactivity rate shows three distinct peaks of reactivity, whereas the control shows one small peak and one main peak. The first peak at 40 °C for the prepolymer indicates a higher reactivity than the control and could point to a potential resin pre-cure. The second peak or the pre-polymer has the largest rate increase from 50 to 80 °C and is clearly reacting faster than the control 541. A third peak happens within the cure onset zone as the temperature rises faster to a peak temperature of 156 °C vs 120 °C for the 541 peak temperature. This is indicating an increased exothermic reaction which can help drive the core temperature of the panel up faster than the control resin. In Table 3, temperature times and reactivity rate can be seen with the pre-polymer clearly reacting faster than the control 541.

Reactivity Rate Comparison

In Figure 7, all the prepolymer resins clearly show an increased reactivity with at least two to three distinctive peaks with all of them occurring before the control resins peak reaction rate. Resins A and B show three peaks with each having a different maximum reactivity rate. Resins C and D both have high initial rate peaks and may indicate potential for pre-cure, but have elongated secondary peaks that indicates a higher reactivity. Resins A and B both have the same three peaks but at different rates. This is mainly because resins A and B both have the same additive but at different percentages, with resin A being the higher. In Table 4, resins A, B and C clearly show they react faster and reach 100 °C before the other resins.

So what do these rates tell us? Samples A, B, C and D are somewhat similar in reaction other than the three reaction peaks that samples A and B exhibit. All four prepolymers appear to have similar reactivity times. As the samples reach cure temperatures (100 – 110 °C), samples B and C look to be the most reactive with the fastest overall times. It confirms that all of the prepolymers have higher maximum rate increases, faster times to reach 80°C and much shorter times to reach the curing temperatures than the 541 control. From the results in Table 4, we can now get a feel for the material's rate of reactivity and develop a panel pressing program to evaluate the resin speed in an actual press environment.

Lab Panel Results

With temperature and reactivity data available, we then took our evaluation to the next step, which involved impregnating and pressing particleboard panels. We then began to evaluate press cook times. Cook time can be defined as the time it takes to cure a panel once it reaches target thickness until the press is ready to open to the de-gas stage. A base cook time of 130 seconds was used as a control time. This is the standard for PMDI for most particle board mills at the given thickness. In Table 5, we compare the various press times with the internal bond strength of the panels. At the control 130 second time, all of the IB’s (internal bond) are high and far exceed the 100 psi internal bond target which is to be expected. As we lower the time by five seconds, slight decreases can be seen in IB but not enough to be alarmed. One could even lower the cook time to 125 second and the properties would not change much.

As we lower the cook time by another 5 seconds and go to 120 seconds we begin to see differences. The internal bond strength begins to drop, particularly for the control, but it is still in the control range. We know from the reactivity profiles that the 541 is the slowest reacting, so when we open the press earlier, the resin bonds are not as fully formed and the internal bond strength will decrease. As we continue to decrease the press time to 115 seconds, we now see that the control 541 internal bond strength has dropped below the 100 psi target range and would fail. In a mill setting, correcting this issue would either add more press time (lower productivity) or increase the resin content (less efficient/economical). All of the other resins continue to meet the spec of 100 psi. With the next step down in press time to 110 seconds, this is where the strong (bond) shall survive. The 541 control did not hold together at all and split at the press opening. This is caused from poor bond formation with the panel and the internal gas pressure of the panel exceeding the bond strength. Resins A, B and D did not meet the 100 psi target but still had decent bond strength. Only resin C met the 100 psi internal bond target which was expected as it also had the fastest reactivity times.

Conclusion

Results from the pilot run demonstrated that the particle boards made with the prepolymer PMDI resin had better properties and at lower press times than the control. This confirms that we have lowered the reaction onset temperature and the panel internal bond results indicate that the prepolymer PMDI has potentially increased the efficiency of the bonding as indicated by the internal bond strength and reduced press times. The resins are also storage stable for 6 months (when stored under recommended storage conditions). The material requires no mill dosing equipment, is easy to handle (stable) with no apparent pre-curing of the resonated wood. We are currently continuing the study by performing long-term durability studies, analyzing the effects of moisture contents, of wood species and optimizing process parameters for optimal mill production.

References

1. R.N Hunt, J.W Rosthauser, W.S. Gustavich, K.W. Haider “ MOISTURE-CURING POLYMERIC- CURING WOOD BINDERS” presented at The Forest Products Society in Merida, Mexico June 1998.

2. J.W. Frink, H.D Layton “CURING PROFILE OF POLYMERIC MDI IN HARDWOOD FLAKEBOARD BONDING SYSTEMS”, Presented at the SPI 28th Technical /Marketing Conference.

3. U.S. Patent 6022444 Bayer Corporation, “MODIFIED PMDI FOR FASTER PRESS TIMES OR LOWER PRESS TEMPERATURES OF MDI FROM HOT PRESSES”.

4. T.M.Gruver , N.R. Brown, J.S Cionni, T.S.McCracken, W.J Nicola , T.Takah 2007, EFFECT OF SELECTED WOOD SPECIES AND MOISTURE CONTENT AND MOISTURE CONTENT ON PMDI RESIN APPLICATION AND PANEL PROPERTIES”. Wood and Fiber Science, April 2008, V. 40(2).

5. D.A. Redlinger, Naajian Sun, Charles E. Frazier, Tg AN INDEX OF CONVERSION IN PMDI- IMPGREGNATED WOOD, NCSU.EDU. Bioresources, Oct. 17, 2007.

6. ASTM (2006) Method D 1037-06a. AMERICAN SOCIETY FOR TESTING AND MATERIALS.