Charles W. Thurston01.07.19

SolarWindow Technologies has raised $25 million through an equity transaction to purchase equipment and hire personnel required for manufacturing electricity-generating organic photovoltaic-coated glass, according to a November statement by John Conklin, CEO of the Scottsdale-based company. The company did not reply to requests for information.

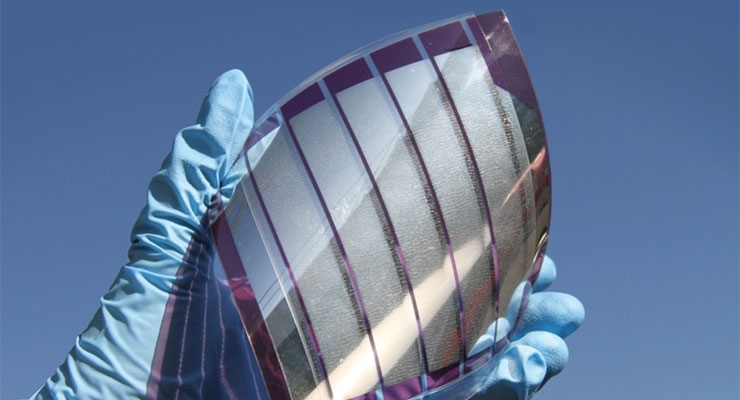

The company’s organic photovoltaic (OPV) technology is based on organic compounds applied to the surface of glass that absorb light and release an electron flow. The coatings are designed for application on glass used in buildings, either as building-integrated construction components or as an after-market application.

OPV experiments ongoing around the world have achieved solar energy conversion efficiencies near 15 percent, about half that of traditional silicon cells. A team at the Nankai University in Tianjin reported a 17.3 percent world record for OPV efficiency in August.

One other limitation of the emerging technology is that long-term reliability still presents significant barriers.

However, unlike traditional silicon crystal solar cells that are relatively expensive to manufacture, a refined OPV technology should cost far less. This is one reason that the U.S.

Department of Energy finances OPV: it is made up of common elements, and the soluble organic molecules enable roll-to-roll processing techniques that allow for low-cost manufacturing, the agency says.

SolarWindow in March was awarded a Cooperative Research and Development Agreement (CRADA) grant for Advanced Manufacturing after submitting a proposal outlining its process technologies and fabrication methods to DOE’s Roll-to-Roll Advanced Materials Manufacturing Consortium. The consortium is led by Oak Ridge National Laboratory (ORNL) and partnering with Argonne National Laboratory (ANL), Lawrence Berkeley National Laboratory (LBNL) and the National Renewable Energy Laboratory (NREL).

The CRADA is being carried out through cooperation between SolarWindow, ANL and NREL.

The company has not revealed the value of the agreement nor its completion date, and the public version of the DOE document is redacted to occlude the information.

In August, SolarWindow concluded a “Process Integration and Production Agreement” with TriView Glass Industries, a glass fabricator with a manufacturing facility in City of Industry, California. The primary goals of the agreement are to “establish commercial-scale manufacturing methodologies and processes to fabricate products based on (SolarWindow) technologies, to integrate SolarWindow process technologies into the Triview manufacturing process, and to fabricate specific transparent electricity generating SolarWindow products,” the company said.

In June, SolarWindow forged an agreement with Dallas-based nTact, a coatings process and equipment manufacturing company, with the aim of acquiring the machinery necessary for large-scale production of transparent electricity-generating windows.

The two companies will work “to design, prototype, test and manufacture machinery and equipment necessary for coating glass and flexible materials with the company’s transparent electricity-generating coatings, which will be used to create a manufacturing line, with the goal of implementing large-scale production of SolarWindow electricity-generating glass and flexible products.”

SolarWindow also is cooperating with Raynergy Tek, an organic photovoltaics technology company, based in Taiwan.

The company’s proprietary OPV energy generation software model was reviewed in 2015 by a team at the University of North Carolina’s Charlotte Energy Production and Infrastructure Center, the company noted. “The model calculates a financial payback of less than one year for our transparent electricity generating technology,” the company said.

SolarWindow, which is a publicly-traded penny stock, has filed over 60 U.S. and international patent and 30 trademark applications for its electricity generating coating and technology development.

The company’s organic photovoltaic (OPV) technology is based on organic compounds applied to the surface of glass that absorb light and release an electron flow. The coatings are designed for application on glass used in buildings, either as building-integrated construction components or as an after-market application.

OPV experiments ongoing around the world have achieved solar energy conversion efficiencies near 15 percent, about half that of traditional silicon cells. A team at the Nankai University in Tianjin reported a 17.3 percent world record for OPV efficiency in August.

One other limitation of the emerging technology is that long-term reliability still presents significant barriers.

However, unlike traditional silicon crystal solar cells that are relatively expensive to manufacture, a refined OPV technology should cost far less. This is one reason that the U.S.

Department of Energy finances OPV: it is made up of common elements, and the soluble organic molecules enable roll-to-roll processing techniques that allow for low-cost manufacturing, the agency says.

SolarWindow in March was awarded a Cooperative Research and Development Agreement (CRADA) grant for Advanced Manufacturing after submitting a proposal outlining its process technologies and fabrication methods to DOE’s Roll-to-Roll Advanced Materials Manufacturing Consortium. The consortium is led by Oak Ridge National Laboratory (ORNL) and partnering with Argonne National Laboratory (ANL), Lawrence Berkeley National Laboratory (LBNL) and the National Renewable Energy Laboratory (NREL).

The CRADA is being carried out through cooperation between SolarWindow, ANL and NREL.

The company has not revealed the value of the agreement nor its completion date, and the public version of the DOE document is redacted to occlude the information.

In August, SolarWindow concluded a “Process Integration and Production Agreement” with TriView Glass Industries, a glass fabricator with a manufacturing facility in City of Industry, California. The primary goals of the agreement are to “establish commercial-scale manufacturing methodologies and processes to fabricate products based on (SolarWindow) technologies, to integrate SolarWindow process technologies into the Triview manufacturing process, and to fabricate specific transparent electricity generating SolarWindow products,” the company said.

In June, SolarWindow forged an agreement with Dallas-based nTact, a coatings process and equipment manufacturing company, with the aim of acquiring the machinery necessary for large-scale production of transparent electricity-generating windows.

The two companies will work “to design, prototype, test and manufacture machinery and equipment necessary for coating glass and flexible materials with the company’s transparent electricity-generating coatings, which will be used to create a manufacturing line, with the goal of implementing large-scale production of SolarWindow electricity-generating glass and flexible products.”

SolarWindow also is cooperating with Raynergy Tek, an organic photovoltaics technology company, based in Taiwan.

The company’s proprietary OPV energy generation software model was reviewed in 2015 by a team at the University of North Carolina’s Charlotte Energy Production and Infrastructure Center, the company noted. “The model calculates a financial payback of less than one year for our transparent electricity generating technology,” the company said.

SolarWindow, which is a publicly-traded penny stock, has filed over 60 U.S. and international patent and 30 trademark applications for its electricity generating coating and technology development.