04.05.19

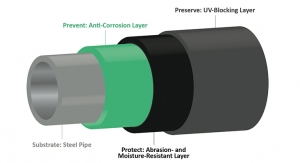

Sherwin-Williams Protective & Marine Coatings launched Dura-Plate 6000, a new 100 percent solids, high-build, high-strength, reinforced epoxy lining for concrete and steel in severe wastewater service environments. The durable lining material offers asset owners and applicators a variety of time and cost efficiencies due to its fast return-to-service times and the option for single-leg application. In addition, it provides long-term life expectancy due to its extremely low permeability and excellent chemical resistance.

Dura-Plate 6000 reinforced epoxy lining provides high film build characteristics and a variety of other properties to deliver easier, more cost-effective installations compared to other fiber or microfiber filled products. Reinforced with glass flakes, the material can be applied more than 125 mils thick in a single spray, potentially reducing the need for additional coats. The product’s ability to be sprayed using a single leg application eliminates the expenses of renting a generator and using a plural pump operator. Providing additional cost savings potential, Dura-Plate 6000 has a long pot life, helping applicators reduce waste material, as well as a 21-day extended recoat window, which helps applicators reduce missed recoats. In addition, the lining does not require a glaze coat like other reinforced products.

“Dura-Plate 6000 answers our customers’ needs for a 100 percent solids reinforced epoxy lining system that eliminates the application challenges associated with other fiber or microfiber filled products, which tend to sag at higher film builds and require additional steps,” said Kevin Morris, global market director – Infrastructure for Sherwin-Williams Protective & Marine Coatings. “By focusing on ease of use and more flexible application characteristics with this product, we are enabling applicators to perform faster-lining installations and increase production rates, while realizing significant cost savings potential.”

The reinforced epoxy lining material is rated for immersion service in a variety of severe environments, including headworks and primary treatment plants for wastewater operations, as well as manholes, wet wells and pump stations for sewer collection. It can be applied over properly prepared steel and concrete surfaces in these and other environments to deliver long-term service.

Dura-Plate 6000 reinforced epoxy lining provides high film build characteristics and a variety of other properties to deliver easier, more cost-effective installations compared to other fiber or microfiber filled products. Reinforced with glass flakes, the material can be applied more than 125 mils thick in a single spray, potentially reducing the need for additional coats. The product’s ability to be sprayed using a single leg application eliminates the expenses of renting a generator and using a plural pump operator. Providing additional cost savings potential, Dura-Plate 6000 has a long pot life, helping applicators reduce waste material, as well as a 21-day extended recoat window, which helps applicators reduce missed recoats. In addition, the lining does not require a glaze coat like other reinforced products.

“Dura-Plate 6000 answers our customers’ needs for a 100 percent solids reinforced epoxy lining system that eliminates the application challenges associated with other fiber or microfiber filled products, which tend to sag at higher film builds and require additional steps,” said Kevin Morris, global market director – Infrastructure for Sherwin-Williams Protective & Marine Coatings. “By focusing on ease of use and more flexible application characteristics with this product, we are enabling applicators to perform faster-lining installations and increase production rates, while realizing significant cost savings potential.”

The reinforced epoxy lining material is rated for immersion service in a variety of severe environments, including headworks and primary treatment plants for wastewater operations, as well as manholes, wet wells and pump stations for sewer collection. It can be applied over properly prepared steel and concrete surfaces in these and other environments to deliver long-term service.