Otto Soidinsalo, Synnøve Holtan, Ali Moosavifar, Borregaard, Sarpsborg, Norway05.31.19

Abstract

There is a growing interest to move toward waterborne systems in the coatings industry due to environmental and occupational health reasons. However, the change is not always straightforward and often new technologies are required to obtain the same performance as with solventborne systems.

Microfibrillated cellulose (MFC), a value-added and multifunctional product made of cellulose, consists of fibers with lateral dimensions in the nanoscale range and lengths up to the micron scale. The main characteristic of this unique fiber structure is its resemblance to both water-soluble polymers and insoluble additives, leading to a versatile and efficient alternative to technologies currently available. The high inertness, compatibility and stability of MFC opens up new possibilities for waterborne coatings, especially for the more demanding formulations. MFC secures high viscosity at rest, giving good stability, as well as offering shear thinning behavior and rapid viscosity build-up, which prevents sag during application.

The aim of this work was to evaluate the effect of MFC on the rheological behavior of the coating formulation as well as on the final film properties. Waterborne exterior flat paint, based on a blend of acrylic and vinyl acrylic binders, was used to investigate the effect of MFC on the prevention of syneresis as well as mud cracking of the coating. Deep base acrylic paint was used to evaluate the effectiveness of MFC in preventing viscosity loss on tinting, color float and sagging.

We demonstrate how MFC can solve typical challenges in waterborne high-quality architectural coatings regarding, for example, mud-cracking, viscosity loss upon tinting, sagging and sprayability.

Introduction

It is commonly known that waterborne formulations still suffer from several issues and it`s not always possible to obtain the same performance as with solvent-borne systems. One of the typical challenges with waterborne systems is related to the relatively rapid drying of the film leading to short open time. The short open time naturally creates challenges regarding the workability as well as the applicability. Short open times also set limits on the wet thickness of the film. Mud cracking is often observed when thick layers are applied and the drying takes place at low temperatures. Another challenge in waterborne systems is related to the behavior of rheology modifiers in the presence of surfactants as well as under extreme pH conditions. The common rheology modifiers can be divided roughly into two categories, associative and non-associative. The former is typically sensitive to the presence of surfactants and this is often seen after the tinting of the base paint. In most cases, the viscosity of the paint reduces as a consequence of disturbance in the associative network due to the surfactants present in the tinting paste.

Microfibrillated cellulose (MFC) is a multifunctional additive for coatings, adhesives and sealants, with a pronounced effect in improving rheology, stabilization and surface properties. MFC is suitable for a wide variety of polar organic and waterborne systems, enabling the control of viscosity and modification of thixotropy of various water and polar solvent-based systems. The high inertness, compatibility and stability of MFC allows the development of stable and robust formulations, even under demanding conditions. In addition, MFC offers solutions for formulators for improved anti-settling, anti-syneresis and anti-cracking of the coatings formulations.

The compatibility and rheological behavior of microfibrillated cellulose has previously been studied in water-based acrylic and epoxy systems.1,2 The results from these studies showed that MFC dispersed very well into the resins and showed good compatibility. In addition, the viscosity and sag resistance increased with increasing concentration of MFC. Furthermore, the dispersions were heat stable in terms of sedimentation and retention of rheological properties.

The unique rheological properties of MFC lead to better control of the formulations by controlling the flow of the particles. It has been shown that MFC can prevent the coffee-ring effect during the drying process of films, leading to a better distribution of particles and pigments.3 This opens up possibilities for increased effectiveness and better color development of pigments and fillers, such as titanium dioxide.

Microfibrillated Cellulose

Microfibrillated cellulose was first introduced back in the eighties.4 During the years its potential and possible uses have been reported extensively, ranging from use as a thickener in cosmetics to an oxygen barrier in food packaging.5 Until the beginning of 2010 the research and small scale production of MFC was conducted mainly at universities and small pilot facilities. Borregaard launched the commercial production of MFC, opening a 1000 Dry MT Exilva factory in 2016 as the first one in the world.6

MFC consists of long and thin cellulose fibrils which form a three-dimensional (3D) network. The secret behind the unique properties is the extremely large surface area, combined with numerous hydroxyl groups on the surface of the fibrils. The interaction of MFC is based on physical as well as on chemical interaction in the formulation. The main characteristics of this unique fibril structure resembles a hybrid of water-soluble polymers and insoluble additives. MFC has high viscosity and yield stress, it is shear thinning and has high water holding capacity. The insoluble nature of the cellulose fibrils also leads to excellent stability and compatibility. MFC is stable at wide pH range (1-13) and is compatible with common water-miscible organic solvent as well as with surfactants.

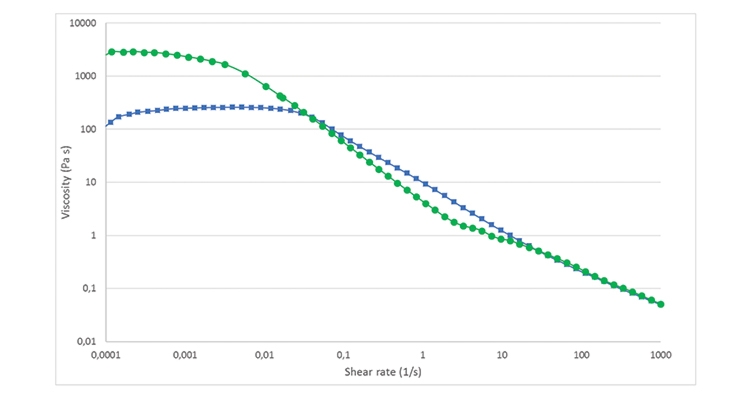

Compared to common polymer solutions in water, the rheological properties of MFC suspensions are quite different. First of all, the viscosity does not reach a plateau at low shear as it normally does in polymer solutions. This can be seen in Figure 1, which shows that the viscosity of MFC suspension increases as the shear rate decreases. Instead, the viscosity of xanthan gum solution reaches a plateau around the shear rate of 0.1 s-1. This means that the viscosity at rest is much higher for MFC, in this case nearly 50 times higher, meaning considerably better stability under storage, especially in terms of syneresis and settling. At higher shear rates, xanthan gum solution and MFC suspension have comparable shear thinning which helps in pumping, spraying, mixing and application of the formulation.

Due to the high viscosity at low shear rate and very shear thinning behavior, MFC can also be used as a thickener in products that are intended to be applied by spraying. MFC secures high stability during storage and allows the spraying of very thick suspensions since the viscosity decreases during the spraying. However, when the product has been applied and no forces are applied, the viscosity recovers quickly, and the product remains where it impacted the surface without sagging (Figure 2). In addition to anti-sagging, the use of MFC leads to a non-dripping effect, which is often desired in coatings.

Materials and Methods

Commercially available MFC (Exilva® F 01-V) was used in this study, containing 10 wt% microfibrillated cellulose in water (manufactured by Borregaard). The anti-mud-cracking effect of MFC was studied with an exterior acrylic paint formulation. A paint sample was applied by a Leneta Anti Sag Meter (14-60 mils) to the reverse side of Leneta Form 9A charts at ambient temperature and at 2 °C. The paints were allowed to dry in a flat position for 24 hours. The greatest mils without mud-cracking were reported. Sag resistance (tinted) was determined according to ASTM D4440, flow and levelling (tinted) according to ASTM D4062, gloss (tinted) according to ASTM D523 and scrub resistance according to ASTM D2486.

Results and Discussions

In order to understand the behaviour of MFC in waterborne systems, two different formulations were studied. Acrylic exterior flat coating was used to demonstrate the impact of MFC on drying behaviour of the curing film as well as the storage stability of the formulation. Interior acrylic deep base formulation was used to investigate the effect of MFC on viscosity loss after tinting as well as rheological and surface properties of the coating.

Acrylic Coating - Storage Stability and Drying Behaviour

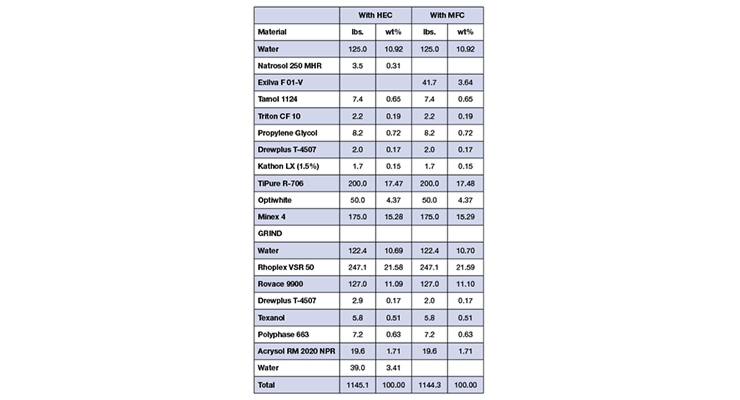

The effect of MFC on storage stability and film properties was studied with exterior flat paint (Table 1). The formulation was based on a blend of acrylic and vinyl acrylic binders, with either hydroxyethyl cellulose (HEC) as a thickener or MFC as a functional additive. In both cases, non-ionic urethane rheology modifier (HEUR) was used to adjust the high-shear viscosity.

In addition to the rheology modification, the formulation based on MFC displayed increased mudcrack resistance during curing from 35 °F to 75 °F, outperforming the same formulation when based on HEC. With MFC, no cracking was observed even at 60 mils thickness, whereas the HEC paint displayed cracking for all thicknesses above 14 mils (Figure 3). The improved mud crack resistance is a consequence of the effect of MFC on the drying of the film. During the drying, MFC does not form a “skin” on top of the film, allowing the solvents to evaporate freely. MFC also increases the open time of the formulation as well as reduces the tackiness of the film. A clear difference in stability was also seen between the two formulations after two weeks’ heat stability testing at 120 °F. The formulation based on HEC showed moderate syneresis, whereas no syneresis was observed with the formulation based on MFC (Figure 4).

Effect of MFC on the Loss of Viscosity and Color Float of an Acrylic Coating Upon Tinting

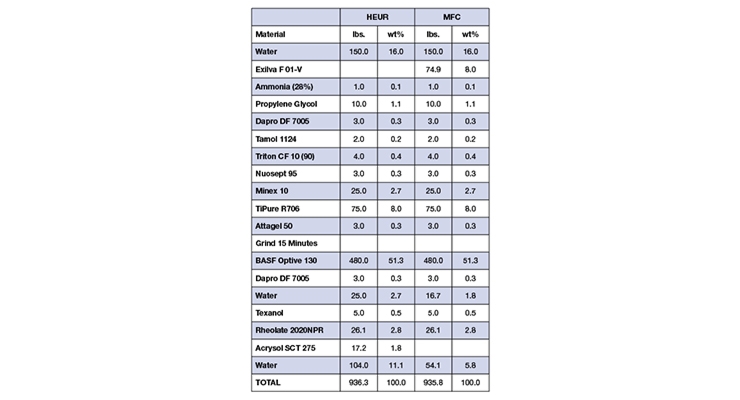

The effect of MFC on film properties as well as its ability to prevent loss on tinting and color float was studied with an acrylic deep base formulation (Table 2). The formulation was based on an acrylic binder, with either non-ionic urethane modifier (HEUR) as a thickener or MFC as a functional additive. In both cases, HEUR thickener was used to adjust the high shear viscosity.

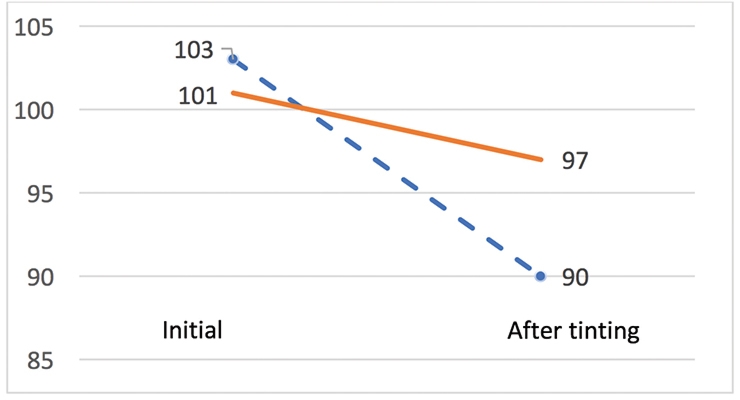

The effect of MFC on viscosity retention after tinting with 808-9907 Lamp Black (8 ounces per gallon) can be clearly seen from Figure 5. The viscosity of the HEUR-based formulation drops 12.6 %, whereas the formulation based on MFC only 4.0 %. The difference can be explained by the physical nature of the MFC fibrils. The thickening effect of MFC is based on the physical interaction with the fibrils as well as the hydrogen bonding with the other components in the system. Therefore, the network is not affected by the presence of surfactants or other hydrophobic compounds.

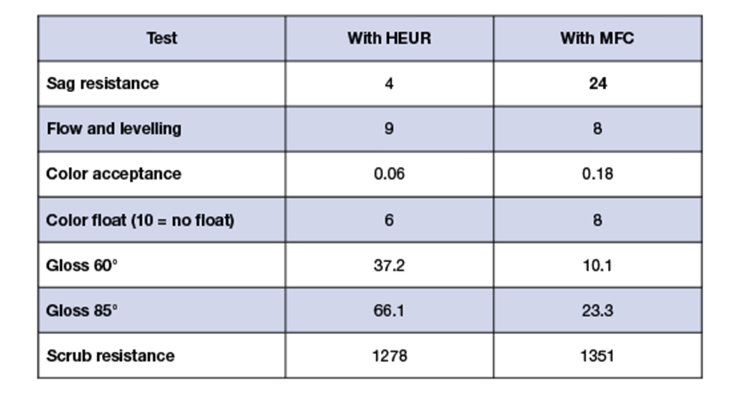

A major difference was also noticed on sagging (Table 3). The high viscosity at rest and relatively fast viscosity recovery of MFC, resulted in a sag resistance rating of 24 according to ASTM D4400, whereas the formulation based on HEUR resulted in a sag rating of 4. Color acceptance was at a similar level for both formulations. Color float was slightly lower for MFC. A strong effect on gloss was noticed when MFC was used as a rheology modifier. The gloss for the HEUR-based formulation was 37.2 (60°), whereas for the MFC-based formulation it was 10.1. As the levelling for both formulations was at a similar level, 9 for HEUR and 8 for MFC (ASTM D4062), the loss on gloss is thought to be related to the physical structure of the MFC fibrils, leading to a mattifying effect. This also means that MFC can be used to formulate smooth surface flat paints, at higher dosage levels. Both formulations showed good scrub resistance, with MFC showing slightly higher resistance (1351 vs 1278).

Conclusions

The effect of MFC on the rheology of the coating formulations as well as on the film properties is prominent. The effect is especially significant at low-temperature film formation, offering huge benefits when applying MFC in high-quality exterior paints for cold climates. MFC enables increased applied film thickness, thereby reducing the number of applied film layers required, without comprimising the final coating properties. The high viscosity at rest, combined with high yield stress results in stable formulations and allows homogenous formulations even in the presence of heavy particles or low density fillers. The relatively fast viscosity recovery leads to excellent sag resistance without sacrificing the levelling of the coating. In addition, the 3D MFC network is highly robust and is not affected by the addition of surfactants or changes in pH. MFC prevents viscosity loss after tinting and helps to reduce the color float of the coating. Depending on the dosage of MFC, effect on the gloss of the coating can be seen. This opens up possibilities to formulate smooth surface flat paints. MFC is a sustainable, VOC-free, multifunctional additive which can not only replace synthetic additives in formulations, but also contribute added value to the end products.

REFERENCES

1. A. Moosavifar and S. Holtan, European Coatings Congress proceedings, 2015.

2. A.M. Falkenberg Olsen, S. Holtan and A. Moosavifar, European Coatings Journal, 2015, 07/08, 30.

3. Y. Ooi, I. Hanasaki, D. Mizumura and Y. Matsuda, Science and Technology of Advanced Materials, 2017, 1, 316.

4. A. F, Turbak, F.W. Snyder and K.R. Sandberg, US Patent 4,500,546, 1982.

5. D. Klemm, F. Kramer, S. Moritz, T. Lindström, M. Ankerfors, D. Gray and A. Dorris, (2011) Angewandte Chemie Int. Ed. 2011, 24, 5438.

6. www.exilva.com CW

There is a growing interest to move toward waterborne systems in the coatings industry due to environmental and occupational health reasons. However, the change is not always straightforward and often new technologies are required to obtain the same performance as with solventborne systems.

Microfibrillated cellulose (MFC), a value-added and multifunctional product made of cellulose, consists of fibers with lateral dimensions in the nanoscale range and lengths up to the micron scale. The main characteristic of this unique fiber structure is its resemblance to both water-soluble polymers and insoluble additives, leading to a versatile and efficient alternative to technologies currently available. The high inertness, compatibility and stability of MFC opens up new possibilities for waterborne coatings, especially for the more demanding formulations. MFC secures high viscosity at rest, giving good stability, as well as offering shear thinning behavior and rapid viscosity build-up, which prevents sag during application.

The aim of this work was to evaluate the effect of MFC on the rheological behavior of the coating formulation as well as on the final film properties. Waterborne exterior flat paint, based on a blend of acrylic and vinyl acrylic binders, was used to investigate the effect of MFC on the prevention of syneresis as well as mud cracking of the coating. Deep base acrylic paint was used to evaluate the effectiveness of MFC in preventing viscosity loss on tinting, color float and sagging.

We demonstrate how MFC can solve typical challenges in waterborne high-quality architectural coatings regarding, for example, mud-cracking, viscosity loss upon tinting, sagging and sprayability.

Introduction

It is commonly known that waterborne formulations still suffer from several issues and it`s not always possible to obtain the same performance as with solvent-borne systems. One of the typical challenges with waterborne systems is related to the relatively rapid drying of the film leading to short open time. The short open time naturally creates challenges regarding the workability as well as the applicability. Short open times also set limits on the wet thickness of the film. Mud cracking is often observed when thick layers are applied and the drying takes place at low temperatures. Another challenge in waterborne systems is related to the behavior of rheology modifiers in the presence of surfactants as well as under extreme pH conditions. The common rheology modifiers can be divided roughly into two categories, associative and non-associative. The former is typically sensitive to the presence of surfactants and this is often seen after the tinting of the base paint. In most cases, the viscosity of the paint reduces as a consequence of disturbance in the associative network due to the surfactants present in the tinting paste.

Microfibrillated cellulose (MFC) is a multifunctional additive for coatings, adhesives and sealants, with a pronounced effect in improving rheology, stabilization and surface properties. MFC is suitable for a wide variety of polar organic and waterborne systems, enabling the control of viscosity and modification of thixotropy of various water and polar solvent-based systems. The high inertness, compatibility and stability of MFC allows the development of stable and robust formulations, even under demanding conditions. In addition, MFC offers solutions for formulators for improved anti-settling, anti-syneresis and anti-cracking of the coatings formulations.

The compatibility and rheological behavior of microfibrillated cellulose has previously been studied in water-based acrylic and epoxy systems.1,2 The results from these studies showed that MFC dispersed very well into the resins and showed good compatibility. In addition, the viscosity and sag resistance increased with increasing concentration of MFC. Furthermore, the dispersions were heat stable in terms of sedimentation and retention of rheological properties.

The unique rheological properties of MFC lead to better control of the formulations by controlling the flow of the particles. It has been shown that MFC can prevent the coffee-ring effect during the drying process of films, leading to a better distribution of particles and pigments.3 This opens up possibilities for increased effectiveness and better color development of pigments and fillers, such as titanium dioxide.

Microfibrillated Cellulose

Microfibrillated cellulose was first introduced back in the eighties.4 During the years its potential and possible uses have been reported extensively, ranging from use as a thickener in cosmetics to an oxygen barrier in food packaging.5 Until the beginning of 2010 the research and small scale production of MFC was conducted mainly at universities and small pilot facilities. Borregaard launched the commercial production of MFC, opening a 1000 Dry MT Exilva factory in 2016 as the first one in the world.6

MFC consists of long and thin cellulose fibrils which form a three-dimensional (3D) network. The secret behind the unique properties is the extremely large surface area, combined with numerous hydroxyl groups on the surface of the fibrils. The interaction of MFC is based on physical as well as on chemical interaction in the formulation. The main characteristics of this unique fibril structure resembles a hybrid of water-soluble polymers and insoluble additives. MFC has high viscosity and yield stress, it is shear thinning and has high water holding capacity. The insoluble nature of the cellulose fibrils also leads to excellent stability and compatibility. MFC is stable at wide pH range (1-13) and is compatible with common water-miscible organic solvent as well as with surfactants.

Compared to common polymer solutions in water, the rheological properties of MFC suspensions are quite different. First of all, the viscosity does not reach a plateau at low shear as it normally does in polymer solutions. This can be seen in Figure 1, which shows that the viscosity of MFC suspension increases as the shear rate decreases. Instead, the viscosity of xanthan gum solution reaches a plateau around the shear rate of 0.1 s-1. This means that the viscosity at rest is much higher for MFC, in this case nearly 50 times higher, meaning considerably better stability under storage, especially in terms of syneresis and settling. At higher shear rates, xanthan gum solution and MFC suspension have comparable shear thinning which helps in pumping, spraying, mixing and application of the formulation.

Due to the high viscosity at low shear rate and very shear thinning behavior, MFC can also be used as a thickener in products that are intended to be applied by spraying. MFC secures high stability during storage and allows the spraying of very thick suspensions since the viscosity decreases during the spraying. However, when the product has been applied and no forces are applied, the viscosity recovers quickly, and the product remains where it impacted the surface without sagging (Figure 2). In addition to anti-sagging, the use of MFC leads to a non-dripping effect, which is often desired in coatings.

Materials and Methods

Commercially available MFC (Exilva® F 01-V) was used in this study, containing 10 wt% microfibrillated cellulose in water (manufactured by Borregaard). The anti-mud-cracking effect of MFC was studied with an exterior acrylic paint formulation. A paint sample was applied by a Leneta Anti Sag Meter (14-60 mils) to the reverse side of Leneta Form 9A charts at ambient temperature and at 2 °C. The paints were allowed to dry in a flat position for 24 hours. The greatest mils without mud-cracking were reported. Sag resistance (tinted) was determined according to ASTM D4440, flow and levelling (tinted) according to ASTM D4062, gloss (tinted) according to ASTM D523 and scrub resistance according to ASTM D2486.

Results and Discussions

In order to understand the behaviour of MFC in waterborne systems, two different formulations were studied. Acrylic exterior flat coating was used to demonstrate the impact of MFC on drying behaviour of the curing film as well as the storage stability of the formulation. Interior acrylic deep base formulation was used to investigate the effect of MFC on viscosity loss after tinting as well as rheological and surface properties of the coating.

Acrylic Coating - Storage Stability and Drying Behaviour

The effect of MFC on storage stability and film properties was studied with exterior flat paint (Table 1). The formulation was based on a blend of acrylic and vinyl acrylic binders, with either hydroxyethyl cellulose (HEC) as a thickener or MFC as a functional additive. In both cases, non-ionic urethane rheology modifier (HEUR) was used to adjust the high-shear viscosity.

In addition to the rheology modification, the formulation based on MFC displayed increased mudcrack resistance during curing from 35 °F to 75 °F, outperforming the same formulation when based on HEC. With MFC, no cracking was observed even at 60 mils thickness, whereas the HEC paint displayed cracking for all thicknesses above 14 mils (Figure 3). The improved mud crack resistance is a consequence of the effect of MFC on the drying of the film. During the drying, MFC does not form a “skin” on top of the film, allowing the solvents to evaporate freely. MFC also increases the open time of the formulation as well as reduces the tackiness of the film. A clear difference in stability was also seen between the two formulations after two weeks’ heat stability testing at 120 °F. The formulation based on HEC showed moderate syneresis, whereas no syneresis was observed with the formulation based on MFC (Figure 4).

Effect of MFC on the Loss of Viscosity and Color Float of an Acrylic Coating Upon Tinting

The effect of MFC on film properties as well as its ability to prevent loss on tinting and color float was studied with an acrylic deep base formulation (Table 2). The formulation was based on an acrylic binder, with either non-ionic urethane modifier (HEUR) as a thickener or MFC as a functional additive. In both cases, HEUR thickener was used to adjust the high shear viscosity.

The effect of MFC on viscosity retention after tinting with 808-9907 Lamp Black (8 ounces per gallon) can be clearly seen from Figure 5. The viscosity of the HEUR-based formulation drops 12.6 %, whereas the formulation based on MFC only 4.0 %. The difference can be explained by the physical nature of the MFC fibrils. The thickening effect of MFC is based on the physical interaction with the fibrils as well as the hydrogen bonding with the other components in the system. Therefore, the network is not affected by the presence of surfactants or other hydrophobic compounds.

A major difference was also noticed on sagging (Table 3). The high viscosity at rest and relatively fast viscosity recovery of MFC, resulted in a sag resistance rating of 24 according to ASTM D4400, whereas the formulation based on HEUR resulted in a sag rating of 4. Color acceptance was at a similar level for both formulations. Color float was slightly lower for MFC. A strong effect on gloss was noticed when MFC was used as a rheology modifier. The gloss for the HEUR-based formulation was 37.2 (60°), whereas for the MFC-based formulation it was 10.1. As the levelling for both formulations was at a similar level, 9 for HEUR and 8 for MFC (ASTM D4062), the loss on gloss is thought to be related to the physical structure of the MFC fibrils, leading to a mattifying effect. This also means that MFC can be used to formulate smooth surface flat paints, at higher dosage levels. Both formulations showed good scrub resistance, with MFC showing slightly higher resistance (1351 vs 1278).

Conclusions

The effect of MFC on the rheology of the coating formulations as well as on the film properties is prominent. The effect is especially significant at low-temperature film formation, offering huge benefits when applying MFC in high-quality exterior paints for cold climates. MFC enables increased applied film thickness, thereby reducing the number of applied film layers required, without comprimising the final coating properties. The high viscosity at rest, combined with high yield stress results in stable formulations and allows homogenous formulations even in the presence of heavy particles or low density fillers. The relatively fast viscosity recovery leads to excellent sag resistance without sacrificing the levelling of the coating. In addition, the 3D MFC network is highly robust and is not affected by the addition of surfactants or changes in pH. MFC prevents viscosity loss after tinting and helps to reduce the color float of the coating. Depending on the dosage of MFC, effect on the gloss of the coating can be seen. This opens up possibilities to formulate smooth surface flat paints. MFC is a sustainable, VOC-free, multifunctional additive which can not only replace synthetic additives in formulations, but also contribute added value to the end products.

REFERENCES

1. A. Moosavifar and S. Holtan, European Coatings Congress proceedings, 2015.

2. A.M. Falkenberg Olsen, S. Holtan and A. Moosavifar, European Coatings Journal, 2015, 07/08, 30.

3. Y. Ooi, I. Hanasaki, D. Mizumura and Y. Matsuda, Science and Technology of Advanced Materials, 2017, 1, 316.

4. A. F, Turbak, F.W. Snyder and K.R. Sandberg, US Patent 4,500,546, 1982.

5. D. Klemm, F. Kramer, S. Moritz, T. Lindström, M. Ankerfors, D. Gray and A. Dorris, (2011) Angewandte Chemie Int. Ed. 2011, 24, 5438.

6. www.exilva.com CW