09.18.19

Sherwin-Williams Protective & Marine Coatings has developed a new and improved version of CarClad Macropoxy HS, the economical, effective, high-solids epoxy that is the popular choice for railcar exteriors.

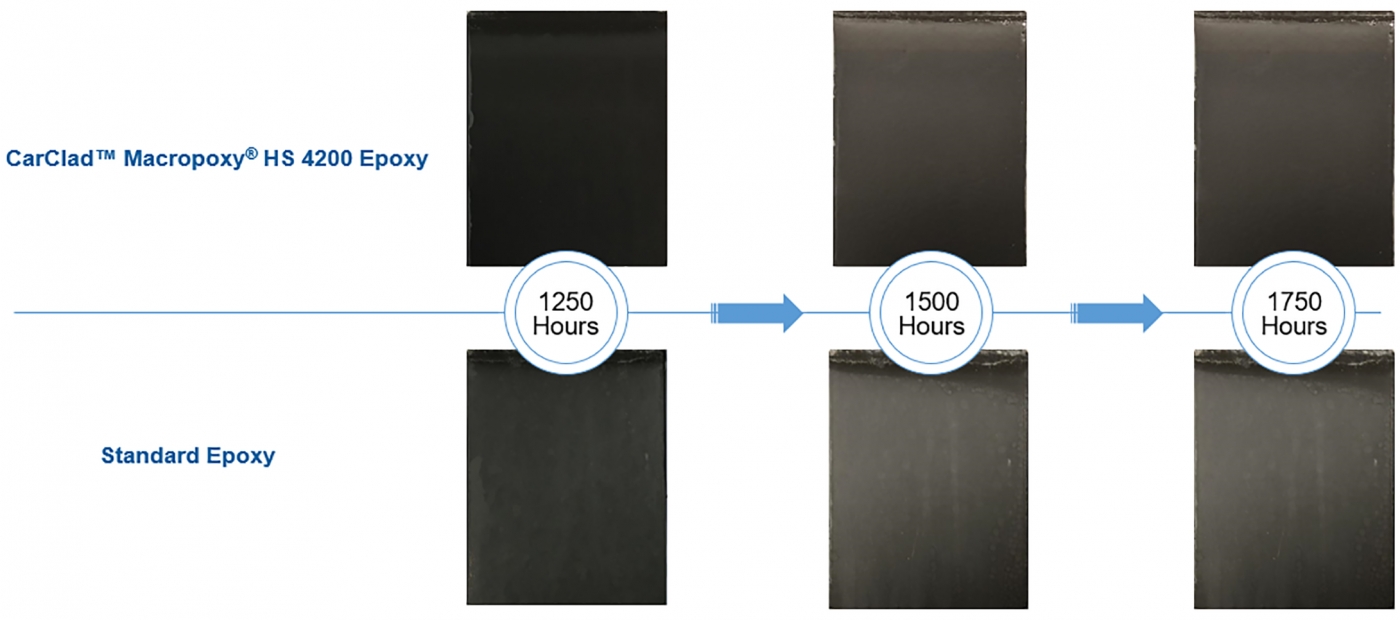

The new product – CarClad Macropoxy HS 4200 extended weathering epoxy – delivers the same long-term corrosion protection and abrasion resistance as its predecessor, and now solves a long-standing aesthetic challenge related to epoxies and UV exposure. While maintaining effective corrosion protection, exterior epoxy coatings tend to change color as they chalk after a year or two in sunlight. For example, black coatings turn to gray. The new CarClad Macropoxy HS 4200 epoxy solves this by chalking black, instead of gray, so black railcars will retain their color and aesthetics much better over their full maintenance interval.

This improvement to high-solids epoxy coatings addresses a growing trend in the industry. While the primary role of the exterior epoxy coating on tanker and hopper cars remains protection from the elements, corrosion and abrasion, railcar owners and leasing companies have begun to hear from their customers – the operators – that they would like tanker and hopper cars to stay black and continue to look attractive over many years. Previously, railcars that had chalked gray after only a couple of years could require a new coating if they were being leased to a new customer. CarClad Macropoxy HS 4200 will reduce costs for railcar owners and lessors because they will no longer have to recoat tanker railcars before the coating’s corrosion-resistant properties have reached the end of their life.

“There has never been any question that CarClad Macropoxy HS epoxy provides many years of effective, economical protection from exterior corrosion on tanker and hopper railcars,” said Michael Manetta, global market director – Rail for Sherwin-Williams Protective & Marine Coatings. “But now we have customers asking us to fix a black exterior appearance issue – and we embraced that challenge. The coating is the first thing you notice when you see a railcar.”

While the main objective of the new product was to improve appearance after UV exposure, CarClad Macropoxy HS 4200 epoxy possesses other virtues that railcar customers value, including flexibility of application. Coating railcars in a time-efficient manner is no easy task due to complex geometries and time demands. CarClad Macropoxy HS 4200 can be applied at the proper film builds (4-6 mils dry film thickness (DFT)) and allows the painter to hang additional wet mils in areas requiring overlapping coats.

CarClad Macropoxy HS 4200 epoxy is also solvent-based, which means there is more latitude in terms of application conditions, such as temperature, than with waterborne epoxies. It can be applied with the same equipment and techniques as the predecessor product, accommodating both single-leg and plural-component sprayers.

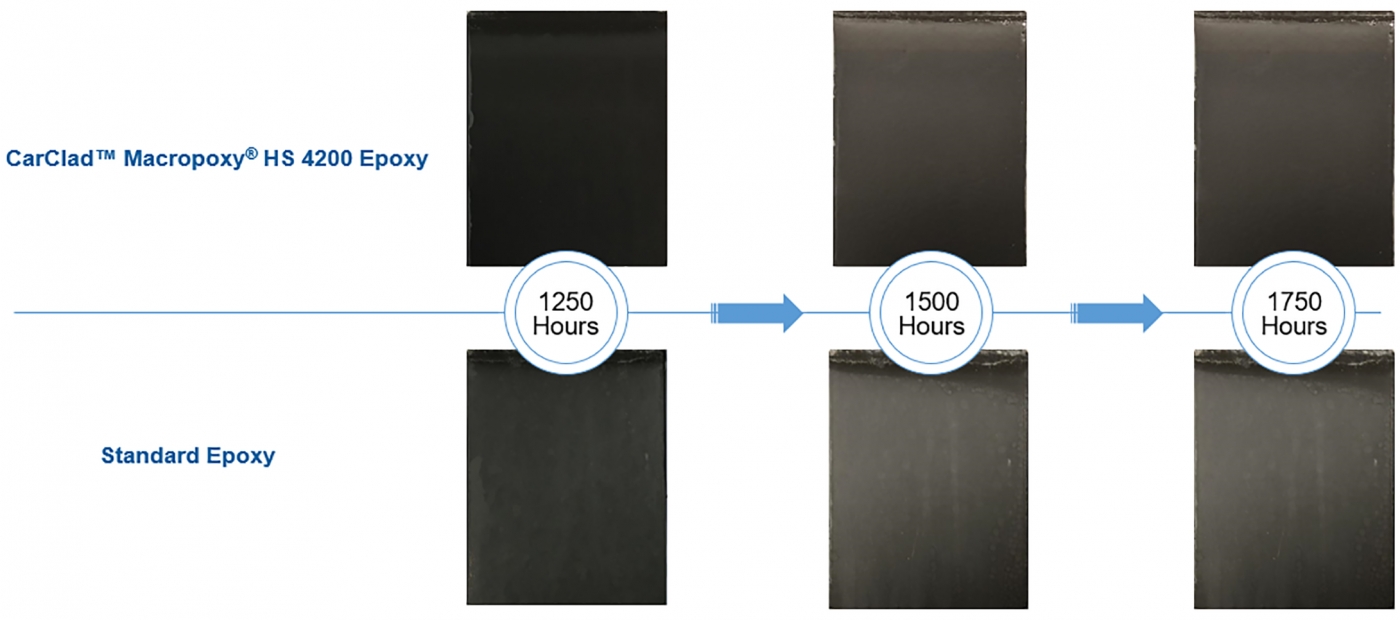

The new product – CarClad Macropoxy HS 4200 extended weathering epoxy – delivers the same long-term corrosion protection and abrasion resistance as its predecessor, and now solves a long-standing aesthetic challenge related to epoxies and UV exposure. While maintaining effective corrosion protection, exterior epoxy coatings tend to change color as they chalk after a year or two in sunlight. For example, black coatings turn to gray. The new CarClad Macropoxy HS 4200 epoxy solves this by chalking black, instead of gray, so black railcars will retain their color and aesthetics much better over their full maintenance interval.

This improvement to high-solids epoxy coatings addresses a growing trend in the industry. While the primary role of the exterior epoxy coating on tanker and hopper cars remains protection from the elements, corrosion and abrasion, railcar owners and leasing companies have begun to hear from their customers – the operators – that they would like tanker and hopper cars to stay black and continue to look attractive over many years. Previously, railcars that had chalked gray after only a couple of years could require a new coating if they were being leased to a new customer. CarClad Macropoxy HS 4200 will reduce costs for railcar owners and lessors because they will no longer have to recoat tanker railcars before the coating’s corrosion-resistant properties have reached the end of their life.

“There has never been any question that CarClad Macropoxy HS epoxy provides many years of effective, economical protection from exterior corrosion on tanker and hopper railcars,” said Michael Manetta, global market director – Rail for Sherwin-Williams Protective & Marine Coatings. “But now we have customers asking us to fix a black exterior appearance issue – and we embraced that challenge. The coating is the first thing you notice when you see a railcar.”

While the main objective of the new product was to improve appearance after UV exposure, CarClad Macropoxy HS 4200 epoxy possesses other virtues that railcar customers value, including flexibility of application. Coating railcars in a time-efficient manner is no easy task due to complex geometries and time demands. CarClad Macropoxy HS 4200 can be applied at the proper film builds (4-6 mils dry film thickness (DFT)) and allows the painter to hang additional wet mils in areas requiring overlapping coats.

CarClad Macropoxy HS 4200 epoxy is also solvent-based, which means there is more latitude in terms of application conditions, such as temperature, than with waterborne epoxies. It can be applied with the same equipment and techniques as the predecessor product, accommodating both single-leg and plural-component sprayers.