Mohammad Ijaz, Kansai Paint05.04.18

Global warming is an imminent threat to our planet, with some serious consequences, and a major contributor to global warming is the urban heat island effect, which is due to rapid urbanization. Urbanization is inevitable, but what we can do to offset its impact is to focus on energy efficiency of new buildings and structures to reduce its impact.

When we talk of buildings and new structures, roofing plays an extremely vital role in the urban heat island. As per the U.S. EPA, 80 percent of the energy conservation of a single story building is through its roof. For any urban area, roofing constitutes almost 70 percent of the surface area of the total urban area. With these facts roofing suddenly plays a pivotal role, internally for the energy conservation of a building and externally for the urban heat island effect.

Conventional Roofing System

The conventional roofing system consists of multiple layers. Each layer has a distinguished purpose and function and, for the efficacy of the complete system, it is mandatory that each layer resonate with each other. The predominant major components of a roofing system are thermal insulations, water proofing and a weathering resistant top layer. Depending on the situation, some other layers are also added such as geotextile membranes and screeding for the slope.

Whenever we design a system with a laminated or layered structure, we are actually designing it to fail, because the joints or seals between the layers will act as weak points in the system and eventually they will degrade or delaminate thus resulting in failure of the complete system.

APOC – Armor Flex

Functional Features

1. Thermal InsulationRoof Cooling

“Thermal insulation” is a phenomenon of a material that reduces the heat transfer between two objects in thermal contact by absorbing and entrapping the heat within itself.

The basic working principal of thermal insulation on a roof is that the insulating material will absorb all heat energy generated from the incident sunlight and will entrap/store that energy and reduce the heat transfer to the roof substrate. Any insulation material’s ability is limited depending on its density, functioning procedure and exposure. Over a period of time, thermal insulation will become a reservoir of heat, sitting on top of a building’s roof and will contribute to significant heat build-up for the building and the environment.

The basic working principal of the Armor Flex Cool roof coating is reflecting the sunlight. By reflecting 90 percent of the sunlight, silicone cool-roof coatings work as an “isolation” layer between the incident sunlight and the roof substrate. Important parameters for a roof cooling product are: reflectivity, emissivity, and solar reflective index (SRI).

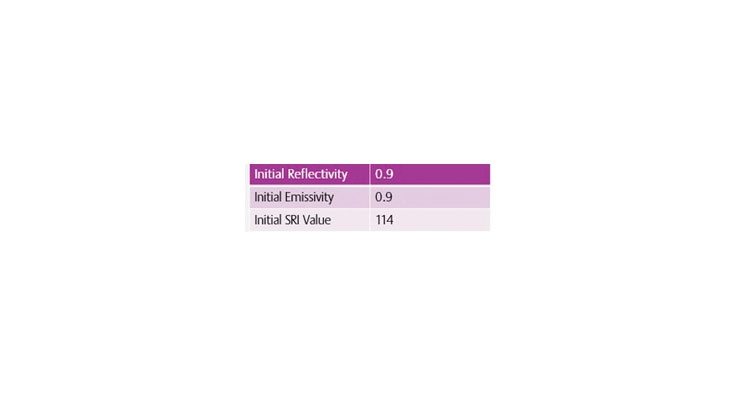

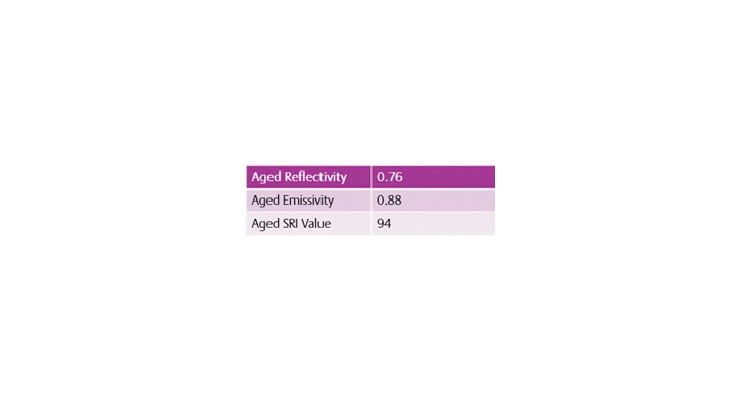

Armor Flex is evaluated not on the initial values but on the aged values for the above-mentioned parameters to demonstrate the actual performance of the coating while in service. Tables 1 and 2 show the initial and aged reflectivity (after 3 years) and the SRI values obtained from the United States independent authority – the Cool Roof Rating Council (CRRC).

Table 1. Armor Flex initial reflectivity, emissivity and SRI value.

Table 2. Armor Flex aged reflectivity, emissivity and SRI value.

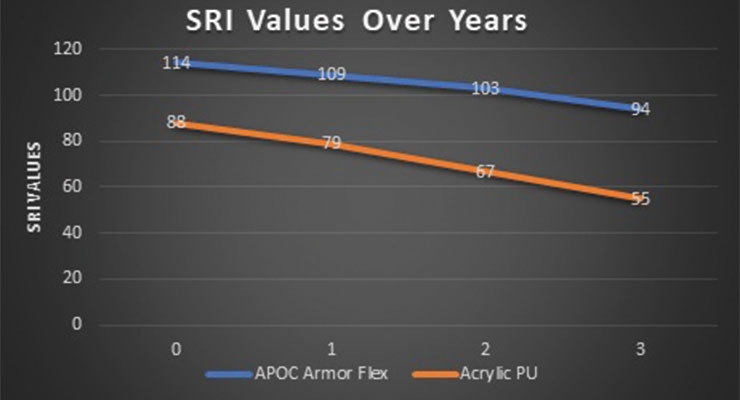

Figure 1. SRI values of Armor Flex and an acrylic PU roof coating over time.

Figure 1 compares the SRI values of APOC Armor Flex and a normal acrylic PU roof coating over time. As per a study carried out by the University of California, Berkeley the tangible gains by using reflective cool roof coatings with a reflectivity value of 0.85, are as follows:

• Reduction in the roof substrate temperature by up to 20°C;

• Reduction in the energy consumption by 48 kWh/m2 per year (in a single story building); and a

• Reduction in the cooling loads by 61 percent.

2. Waterproofing

Waterproofing for roofing is defined as a treatment of the roofing surface in such a way that it not only blocks the contact of water to the roof substrate, but it also blocks the passage of the water. The parameters which determine the quality of any water proofing system are: permeability and water absorption over time (ponding water). The common problems associated with conventional water proofing coatings are: shrinkage, blistering, and adhesive failure.

Armor Flex is engineered to possess the following key features:

• Single-component moisture cured;

• Monolithic membrane (no overlaps or joints);

• Pond proof technology (standing water).

Silicone coatings are formulated so that they possess natural hydrophobic properties. The silicon atoms form an extremely tight bond with the oxygen (Figure 2) and under microscopic examination reveals extremely tiny protrusions, which are smaller than the size of water droplets that act as a complete and permanent barrier to water penetration.

Figure 2. Illustration of a silicone atomic structure.

3. Weathering and UV Resistance

For a roof coating, weather resistance is its ability to prevent degradation or deterioration due to prolonged exposure to harsh environmental and weather conditions.

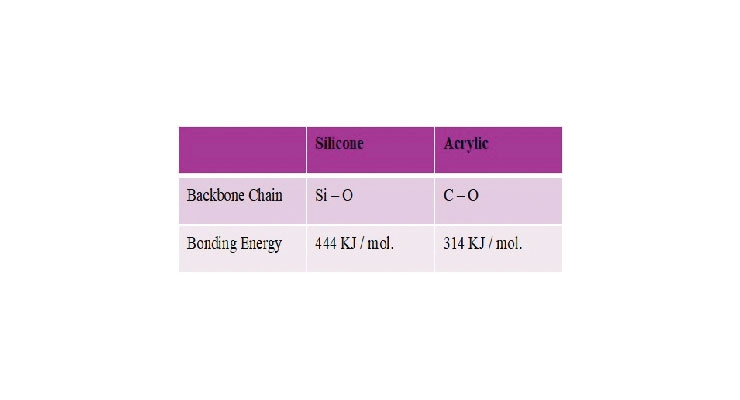

The following two properties of silicon, contribute to extremely photo and thermally stable coatings (Table 3).

• Extremely high inter-atomic bonding energy (Si – O0.163 nm; UV wavelength is in the range of 10 to 400 nm).

• Extremely tight inter-atomic bonding spacing.

Table 3. Comparison of silicon-oxygen and carbon-oxygen bonding energies.

The backbone chain of a silicone coating (silicon and oxygen), due to its strong and tight inter-atomic bonding, will resist any photochemical or thermal degradation in case of UV exposure or any heat build-up.

The conventional acrylic top coat (backbone chain of carbon and oxygen), possesses a much lower atomic bonding energy as compared to that of silicone and that is the reason that acrylics will start to crack and degrade under severe sunlight, often within a few months of application. Plus, acrylics do not possess pond-proof technology, therefore, standing water will cause blistering on the topcoat over time.

4. Fire Rating

Armor Flex offers extremely impressive fire rating properties. It is a UL Certified product and falls under the UL Fire Rating A category, which is essential for any roof coating. It is equally effective against severe fire exposure either on combustible or non-combustible substrates.

5. Durability

When Armor Flex is tested as per ASTM D4798 for its durability, it exhibited extremely durable results. For 5,000 hours under harsh weather conditions and thermal cycling no degradation was observed. This simulated weathering is the equivalent of 30 years in real life as per ASTM D4798.

Due to the decrease in temperature drop of the roof substrate, roof thermal contraction and expansion will reduce drastically, thus improving the roof substrate life span.

6. Environmental Impact

Silicone is an environment friendly and low-VOC product and it normally comes at 98 percent or higher volume solids content.

All the above functional features of Armor Flex in a single component product makes it a “Single Component Complete Roofing System,” whereas, in a conventional roofing system, you need to have various layers, each performing its own function.

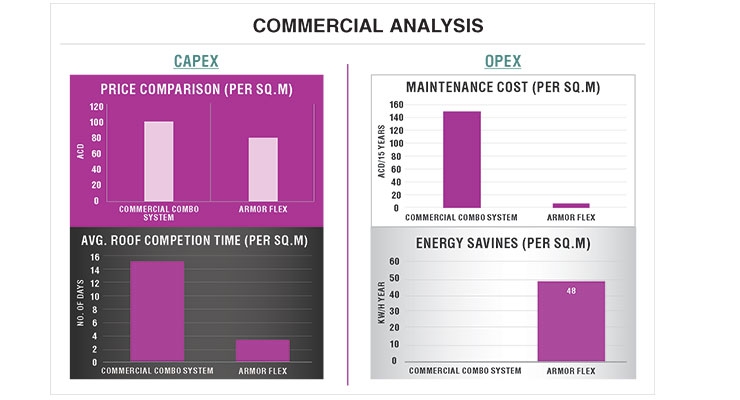

Commercial Analysis

In general, when an innovative product is compared commercially with a conventional system, there are two areas of concern for such a commercial comparison; first is capital expense (CAPEX) and second is operational expense (OPEX). Armor Flex offers commercial benefits not only on the CAPEX side but also significant advantage on the OPEX side, thus giving a return on investment (ROI) within a couple of years of application (Figure 3).

Armor Flex is a unique and innovative coating not only for its ease of application but also for the profound monetary and tangible commercial benefits associated with it. These benefits make it hard to oversee, when considering any roof coating application.

Not only does it reduce the upfront cost as compared to the conventional combo system, but also its ROI is very rapid by significantly reducing routine maintenance cost and real benefits in terms of adding energy savings.

Armor Flex is ideally suited for any new building projects or for any roof restoration projects because it has an adherent feature to go on top of several substrates, such as steel, concrete, wood or any existing roofing system, like bitumen or acrylic, with minimal surface preparation.

Mohammad Ijaz, product manager at Kansai Paint Middle East is a corrosion and coatings engineer by education and has extensive Middle East experience in the field of corrosion and specialized coatings.

When we talk of buildings and new structures, roofing plays an extremely vital role in the urban heat island. As per the U.S. EPA, 80 percent of the energy conservation of a single story building is through its roof. For any urban area, roofing constitutes almost 70 percent of the surface area of the total urban area. With these facts roofing suddenly plays a pivotal role, internally for the energy conservation of a building and externally for the urban heat island effect.

Conventional Roofing System

The conventional roofing system consists of multiple layers. Each layer has a distinguished purpose and function and, for the efficacy of the complete system, it is mandatory that each layer resonate with each other. The predominant major components of a roofing system are thermal insulations, water proofing and a weathering resistant top layer. Depending on the situation, some other layers are also added such as geotextile membranes and screeding for the slope.

Whenever we design a system with a laminated or layered structure, we are actually designing it to fail, because the joints or seals between the layers will act as weak points in the system and eventually they will degrade or delaminate thus resulting in failure of the complete system.

APOC – Armor Flex

Functional Features

1. Thermal InsulationRoof Cooling

“Thermal insulation” is a phenomenon of a material that reduces the heat transfer between two objects in thermal contact by absorbing and entrapping the heat within itself.

The basic working principal of thermal insulation on a roof is that the insulating material will absorb all heat energy generated from the incident sunlight and will entrap/store that energy and reduce the heat transfer to the roof substrate. Any insulation material’s ability is limited depending on its density, functioning procedure and exposure. Over a period of time, thermal insulation will become a reservoir of heat, sitting on top of a building’s roof and will contribute to significant heat build-up for the building and the environment.

The basic working principal of the Armor Flex Cool roof coating is reflecting the sunlight. By reflecting 90 percent of the sunlight, silicone cool-roof coatings work as an “isolation” layer between the incident sunlight and the roof substrate. Important parameters for a roof cooling product are: reflectivity, emissivity, and solar reflective index (SRI).

Armor Flex is evaluated not on the initial values but on the aged values for the above-mentioned parameters to demonstrate the actual performance of the coating while in service. Tables 1 and 2 show the initial and aged reflectivity (after 3 years) and the SRI values obtained from the United States independent authority – the Cool Roof Rating Council (CRRC).

Table 1. Armor Flex initial reflectivity, emissivity and SRI value.

Table 2. Armor Flex aged reflectivity, emissivity and SRI value.

Figure 1. SRI values of Armor Flex and an acrylic PU roof coating over time.

Figure 1 compares the SRI values of APOC Armor Flex and a normal acrylic PU roof coating over time. As per a study carried out by the University of California, Berkeley the tangible gains by using reflective cool roof coatings with a reflectivity value of 0.85, are as follows:

• Reduction in the roof substrate temperature by up to 20°C;

• Reduction in the energy consumption by 48 kWh/m2 per year (in a single story building); and a

• Reduction in the cooling loads by 61 percent.

2. Waterproofing

Waterproofing for roofing is defined as a treatment of the roofing surface in such a way that it not only blocks the contact of water to the roof substrate, but it also blocks the passage of the water. The parameters which determine the quality of any water proofing system are: permeability and water absorption over time (ponding water). The common problems associated with conventional water proofing coatings are: shrinkage, blistering, and adhesive failure.

Armor Flex is engineered to possess the following key features:

• Single-component moisture cured;

• Monolithic membrane (no overlaps or joints);

• Pond proof technology (standing water).

Silicone coatings are formulated so that they possess natural hydrophobic properties. The silicon atoms form an extremely tight bond with the oxygen (Figure 2) and under microscopic examination reveals extremely tiny protrusions, which are smaller than the size of water droplets that act as a complete and permanent barrier to water penetration.

Figure 2. Illustration of a silicone atomic structure.

3. Weathering and UV Resistance

For a roof coating, weather resistance is its ability to prevent degradation or deterioration due to prolonged exposure to harsh environmental and weather conditions.

The following two properties of silicon, contribute to extremely photo and thermally stable coatings (Table 3).

• Extremely high inter-atomic bonding energy (Si – O0.163 nm; UV wavelength is in the range of 10 to 400 nm).

• Extremely tight inter-atomic bonding spacing.

Table 3. Comparison of silicon-oxygen and carbon-oxygen bonding energies.

The backbone chain of a silicone coating (silicon and oxygen), due to its strong and tight inter-atomic bonding, will resist any photochemical or thermal degradation in case of UV exposure or any heat build-up.

The conventional acrylic top coat (backbone chain of carbon and oxygen), possesses a much lower atomic bonding energy as compared to that of silicone and that is the reason that acrylics will start to crack and degrade under severe sunlight, often within a few months of application. Plus, acrylics do not possess pond-proof technology, therefore, standing water will cause blistering on the topcoat over time.

4. Fire Rating

Armor Flex offers extremely impressive fire rating properties. It is a UL Certified product and falls under the UL Fire Rating A category, which is essential for any roof coating. It is equally effective against severe fire exposure either on combustible or non-combustible substrates.

5. Durability

When Armor Flex is tested as per ASTM D4798 for its durability, it exhibited extremely durable results. For 5,000 hours under harsh weather conditions and thermal cycling no degradation was observed. This simulated weathering is the equivalent of 30 years in real life as per ASTM D4798.

Due to the decrease in temperature drop of the roof substrate, roof thermal contraction and expansion will reduce drastically, thus improving the roof substrate life span.

6. Environmental Impact

Silicone is an environment friendly and low-VOC product and it normally comes at 98 percent or higher volume solids content.

All the above functional features of Armor Flex in a single component product makes it a “Single Component Complete Roofing System,” whereas, in a conventional roofing system, you need to have various layers, each performing its own function.

Commercial Analysis

In general, when an innovative product is compared commercially with a conventional system, there are two areas of concern for such a commercial comparison; first is capital expense (CAPEX) and second is operational expense (OPEX). Armor Flex offers commercial benefits not only on the CAPEX side but also significant advantage on the OPEX side, thus giving a return on investment (ROI) within a couple of years of application (Figure 3).

Armor Flex is a unique and innovative coating not only for its ease of application but also for the profound monetary and tangible commercial benefits associated with it. These benefits make it hard to oversee, when considering any roof coating application.

Not only does it reduce the upfront cost as compared to the conventional combo system, but also its ROI is very rapid by significantly reducing routine maintenance cost and real benefits in terms of adding energy savings.

Armor Flex is ideally suited for any new building projects or for any roof restoration projects because it has an adherent feature to go on top of several substrates, such as steel, concrete, wood or any existing roofing system, like bitumen or acrylic, with minimal surface preparation.

Mohammad Ijaz, product manager at Kansai Paint Middle East is a corrosion and coatings engineer by education and has extensive Middle East experience in the field of corrosion and specialized coatings.