10.03.19

Nippon Paint Marine added to its NOA range of self-indicating epoxy coatings with a new system specially developed to protect chemical and product carrier tanks from corrosion and cargo contamination.

NOA PC 700, a phenolic/novolac-based epoxy, is resistant to a wide range of chemicals, solvents and petroleum products, including those containing xylenes, methyl ethyl ketone, methanol, caustic soda and LSA fuel oil.

“The addition of NOA PC 700 to our established NOA range significantly protects inner cargo tanks from corrosion while preventing cargo contamination," said Makoto Nakagawa, GM sales and marketing, Nippon Paint Marine Coatings, Osaka. "As with all our NOA coatings, the application is self-indicating, which enables the applicator to visually confirm the correct wet/dry film thickness has been achieved during the application process. Correct film thickness is crucial to mitigating against corrosion risk to maintain ship structural strength.”

Since the 1998 market launch of the first NOA (Nippon Optimized and Advanced) coating system, Nippon Paint Marine has introduced several different NOA products. And while each one is designed according to the anti-corrosive requirements of different parts of the ship, all the coatings are based on pigments that have various opacities depending on film thickness.

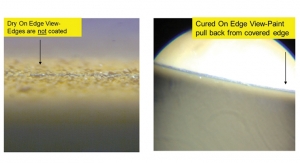

“Achieving correct film thickness, especially on edges and corners, is a challenge but this remarkably simple concept allows shipyard staff, surveyors and coatings inspectors to literally see when the coating has been correctly applied. If the coating appears transparent, then film thickness is incorrect. When it is opaque, correct film thickness has been achieved,” said Nakagawa.

“While NOA application improves coating quality and helps to reduce manhours and costs, the coating system is fundamental to maintaining structural integrity. This is becoming more and more apparent with the increase in areas requiring coating and the reduction in the availability of skilled applicators," said Hiro Yamashita, technical manager, Nippon Paint Marine (Europe).

“In drydock, for instance, our NOA 10M system – specifically developed for hull maintenance and repair – means just one touch-up coat can be applied in the knowledge that the self-indicating function will ensure that the thickness applied is correct. This means fewer days in dock, which contributes to lower drydock costs for the owner. By improving a ship’s corrosion resistance through more accurate coating application, ships are less prone to rusting early.”

With the introduction of NOA PC 700, Nippon Paint Marine hopes to emulate the market success of its NOA60 HS product, which has been applied to the ballast tanks of more than 1,300 newbuild vessels since its introduction in 1998.

NOA60 HS is a superior grade pure epoxy formulated with special phenol-based resins to reinforce resistance to cracking especially on welds, providing greater resistance to saltwater and cathodic disbonding.

Applied in two coats at 160µm per coat, NOA 60HS meets all PSPC acceptance criteria for water and cargo resistance, adhesion, cathodic disbondment, pinholes and undercutting. It is easy to clean and has low emissions of volatile organic compounds.

Suitable for multipurpose use, its enhanced resistance to freshwater and seawater has led to the system becoming the number one coating for ballast tanks and void space protection.

NOA PC 700, a phenolic/novolac-based epoxy, is resistant to a wide range of chemicals, solvents and petroleum products, including those containing xylenes, methyl ethyl ketone, methanol, caustic soda and LSA fuel oil.

“The addition of NOA PC 700 to our established NOA range significantly protects inner cargo tanks from corrosion while preventing cargo contamination," said Makoto Nakagawa, GM sales and marketing, Nippon Paint Marine Coatings, Osaka. "As with all our NOA coatings, the application is self-indicating, which enables the applicator to visually confirm the correct wet/dry film thickness has been achieved during the application process. Correct film thickness is crucial to mitigating against corrosion risk to maintain ship structural strength.”

Since the 1998 market launch of the first NOA (Nippon Optimized and Advanced) coating system, Nippon Paint Marine has introduced several different NOA products. And while each one is designed according to the anti-corrosive requirements of different parts of the ship, all the coatings are based on pigments that have various opacities depending on film thickness.

“Achieving correct film thickness, especially on edges and corners, is a challenge but this remarkably simple concept allows shipyard staff, surveyors and coatings inspectors to literally see when the coating has been correctly applied. If the coating appears transparent, then film thickness is incorrect. When it is opaque, correct film thickness has been achieved,” said Nakagawa.

“While NOA application improves coating quality and helps to reduce manhours and costs, the coating system is fundamental to maintaining structural integrity. This is becoming more and more apparent with the increase in areas requiring coating and the reduction in the availability of skilled applicators," said Hiro Yamashita, technical manager, Nippon Paint Marine (Europe).

“In drydock, for instance, our NOA 10M system – specifically developed for hull maintenance and repair – means just one touch-up coat can be applied in the knowledge that the self-indicating function will ensure that the thickness applied is correct. This means fewer days in dock, which contributes to lower drydock costs for the owner. By improving a ship’s corrosion resistance through more accurate coating application, ships are less prone to rusting early.”

With the introduction of NOA PC 700, Nippon Paint Marine hopes to emulate the market success of its NOA60 HS product, which has been applied to the ballast tanks of more than 1,300 newbuild vessels since its introduction in 1998.

NOA60 HS is a superior grade pure epoxy formulated with special phenol-based resins to reinforce resistance to cracking especially on welds, providing greater resistance to saltwater and cathodic disbonding.

Applied in two coats at 160µm per coat, NOA 60HS meets all PSPC acceptance criteria for water and cargo resistance, adhesion, cathodic disbondment, pinholes and undercutting. It is easy to clean and has low emissions of volatile organic compounds.

Suitable for multipurpose use, its enhanced resistance to freshwater and seawater has led to the system becoming the number one coating for ballast tanks and void space protection.