John McQuillan, Contributing Writer10.11.21

Today’s commercial fleet industry is more competitive than ever. To achieve success in this arena, fleet managers are tasked with making sure trucks look good, run well and stay on the road. If a truck is sidelined for any reason, it can have a negative impact on the bottom line.

Keeping costs down for most fleets typically involves routine scheduled maintenance, regular inspections and prompt, efficient repairs of mechanical problems. One area that’s often overlooked, however, is wheels. While tires are subject to wear and damage and obviously get a lot of attention, wheels carry the load as well.

With exposure to dirt, deicing chemicals, road tar and other debris, wheels can become rusty and corroded over time, and need to be properly maintained, refurbished or replaced before their structural integrity leads to breakdowns—or worse. In fact, since the early 1990s, OSHA has mandated wheel and rim refurbishing for commercial vehicles. The challenge for fleet managers is to find a quality wheel refurbishing solution designed to minimize vehicle downtime.

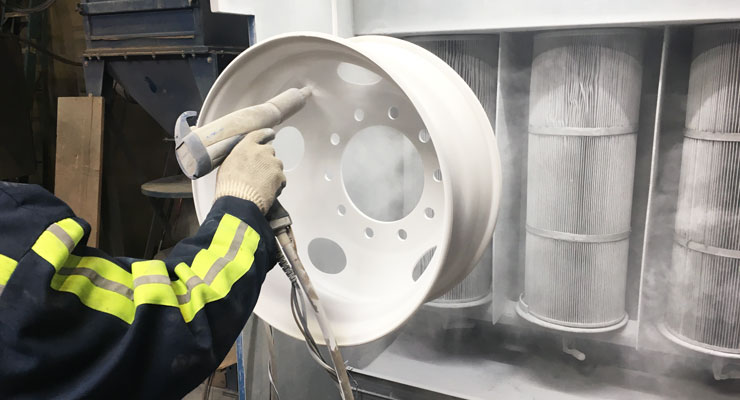

The answer for many fleets is the PPG Wheel Refurbishing Program, featuring the PPG ENVIROCRON™ family of powder coatings. Available to in-house fleet refinish operations, third-party commercial vehicle refinish centers, tire dealers and tire retread providers, the new program was created to efficiently transform rusty, corroded wheels to like-new quality.

“Our customers asked for more than just a powder coating,” explained Jamie White, PPG business development manager, commercial coatings. “With the PPG Wheel Refurbishing Program, we’re providing a comprehensive system designed to improve the efficiency of their refurbishing process while making their finished product look better and last longer. For example, the PPG Envirocron family of powder coatings includes a new, direct-to-metal formulation that delivers exceptional appearance and corrosion protection with no need to prime.”

While white is the most popular color choice for wheels on commercial transport vehicles, PPG Envirocron powder coatings are offered in a wide range of stock and custom colors, which are ideal for companies that want to maintain their brand image across their fleet.

“A truck’s appearance says a lot about the brand,” says White. “And in the competitive space that is today’s commercial transport industry, fleets are looking for every advantage. Dirty, rusty and corroded wheels are not a plus. But when a truck rolls up on a set of wheels that have been refurbished and repainted—in either classic white or a custom color—it gets noticed.”

A crucial component of any wheel refurbishing operation, whether in-house or outsourced, is customer support. When a truck is pulled off the road for wheel refurbishing, time is of the essence.

“Rather than simply provide our customers with a powder coating product, we provide solutions,” explains White. “We approach each customer individually and immerse ourselves in their business to identify ways to improve the quality, and equally important, the speed and efficiency of their wheel refurbishing process. This includes onsite application training, line audits and technical support, just to name a few.”

In addition to individualized customer support, a top level wheel refurbishing program will also offer the advantage of a vast distribution network. This is another area of strength for the PPG Wheel Refurbishing Program.

“PPG retail stores dot the landscape across the United States and Canada,” adds White. “Our wheel refurbishing program utilizes these locations along with our vast refinish and commercial coatings distributor network to provide our wheel refurbishing customers with products and support on a local basis.”

The ability to stock and support wheel refurbishing customers locally is significant, as it can eliminate the need to ship products from distant regions. In turn, this can eliminate freight charges, order minimums and extended wait times—an essential benefit for an industry that places great value on vehicle uptime.

By working closely with customers and providing them with exceptional products, support and distribution logistics, PPG has set the new commercial transport industry standard for the all-important service of wheel refurbishing.

Read more about the PPG Wheel Refurbishing Program featuring the PPG Envirocron family of powder coatings here.

To learn more about the PPG Wheel Refurbishing Program, talk to a PPG wheel refurbishing expert at 501-336-7326.

Keeping costs down for most fleets typically involves routine scheduled maintenance, regular inspections and prompt, efficient repairs of mechanical problems. One area that’s often overlooked, however, is wheels. While tires are subject to wear and damage and obviously get a lot of attention, wheels carry the load as well.

With exposure to dirt, deicing chemicals, road tar and other debris, wheels can become rusty and corroded over time, and need to be properly maintained, refurbished or replaced before their structural integrity leads to breakdowns—or worse. In fact, since the early 1990s, OSHA has mandated wheel and rim refurbishing for commercial vehicles. The challenge for fleet managers is to find a quality wheel refurbishing solution designed to minimize vehicle downtime.

The answer for many fleets is the PPG Wheel Refurbishing Program, featuring the PPG ENVIROCRON™ family of powder coatings. Available to in-house fleet refinish operations, third-party commercial vehicle refinish centers, tire dealers and tire retread providers, the new program was created to efficiently transform rusty, corroded wheels to like-new quality.

“Our customers asked for more than just a powder coating,” explained Jamie White, PPG business development manager, commercial coatings. “With the PPG Wheel Refurbishing Program, we’re providing a comprehensive system designed to improve the efficiency of their refurbishing process while making their finished product look better and last longer. For example, the PPG Envirocron family of powder coatings includes a new, direct-to-metal formulation that delivers exceptional appearance and corrosion protection with no need to prime.”

While white is the most popular color choice for wheels on commercial transport vehicles, PPG Envirocron powder coatings are offered in a wide range of stock and custom colors, which are ideal for companies that want to maintain their brand image across their fleet.

“A truck’s appearance says a lot about the brand,” says White. “And in the competitive space that is today’s commercial transport industry, fleets are looking for every advantage. Dirty, rusty and corroded wheels are not a plus. But when a truck rolls up on a set of wheels that have been refurbished and repainted—in either classic white or a custom color—it gets noticed.”

A crucial component of any wheel refurbishing operation, whether in-house or outsourced, is customer support. When a truck is pulled off the road for wheel refurbishing, time is of the essence.

“Rather than simply provide our customers with a powder coating product, we provide solutions,” explains White. “We approach each customer individually and immerse ourselves in their business to identify ways to improve the quality, and equally important, the speed and efficiency of their wheel refurbishing process. This includes onsite application training, line audits and technical support, just to name a few.”

In addition to individualized customer support, a top level wheel refurbishing program will also offer the advantage of a vast distribution network. This is another area of strength for the PPG Wheel Refurbishing Program.

“PPG retail stores dot the landscape across the United States and Canada,” adds White. “Our wheel refurbishing program utilizes these locations along with our vast refinish and commercial coatings distributor network to provide our wheel refurbishing customers with products and support on a local basis.”

The ability to stock and support wheel refurbishing customers locally is significant, as it can eliminate the need to ship products from distant regions. In turn, this can eliminate freight charges, order minimums and extended wait times—an essential benefit for an industry that places great value on vehicle uptime.

By working closely with customers and providing them with exceptional products, support and distribution logistics, PPG has set the new commercial transport industry standard for the all-important service of wheel refurbishing.

Read more about the PPG Wheel Refurbishing Program featuring the PPG Envirocron family of powder coatings here.

To learn more about the PPG Wheel Refurbishing Program, talk to a PPG wheel refurbishing expert at 501-336-7326.