06.28.19

Royal DSM launched a new direct-to-metal, waterborne coating resin, NeoCryl XK-117.

NeoCryl XK-117 offers a viable alternative to solvent-borne coating technology for the construction and heavy machinery segments and contains low levels of volatile organic compounds, as well as being low in odor.

Moreover, by enabling a direct-to-metal application, rather than requiring the traditional two-stage application, NeoCryl XK-117 enables energy-saving opportunities of up to 50 percent during forced drying processes. What’s more, the new resin enables coatings with high levels of durability, driving the lifetimes of the end products, and helping to reduce our consumption of valuable metal resources.

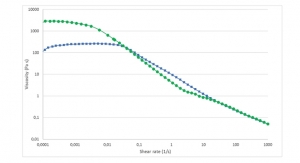

The new resin also delivers a wide range of functional and aesthetic performance benefits, bringing together the diverse properties of traditional multi-step primer-topcoat systems within a single-layer coating solution. In this way, the new resin can help applicators reduce their process times and spatial requirements, without compromising the practical qualities of the end coating. In particular, with a high solid content level of 50 percent, this full-bodied resin can be formulated into high-build coatings to deliver outstanding corrosion resistance, as well as a high-gloss finish.

“The launch of NeoCryl XK-117 is an important step forward for DSM as we look to expand our sustainable direct‑to‑metal product offering, and reinforce our position as the world’s number one waterborne resin producer," said Ap Heijenk, global technical application manager, Industrial Coating Resins DSM. "With the new resin, we are again delivering on our commitment to shaping a more sustainable future in which coating products can perform excellently without damaging the health of people or our planet."